Epoxy floor coating and preparation method thereof

A technology of epoxy floor paint and epoxy curing agent, applied in the field of coatings, can solve the problems of insufficient corrosion resistance of special chemicals, heat resistance, scratch resistance, long-term poor resistance to cold and heat cycles, etc., to improve long-term cold resistance Good thermal cycle performance, good environmental protection performance, and good scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

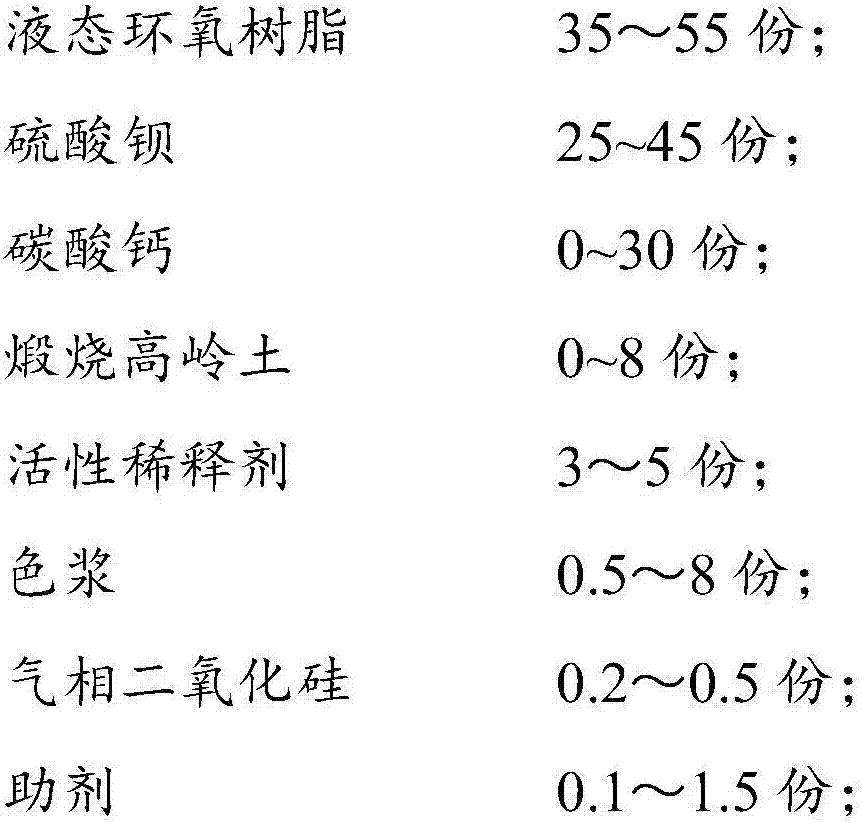

[0038] A kind of epoxy floor paint, each material mass parts are as follows:

[0039] Component A:

[0040]

[0041] Wherein, the color paste is prepared as follows: mix 15 parts of pigment art green, 5 parts of low-viscosity liquid epoxy resin 128, and 3.5 parts of reactive diluent AGE, then add 0.15 parts of BYK 104S dispersant, and disperse at 1200 rpm In 30 minutes, the green color paste was obtained by grinding with a three-roller machine, from which 6 parts were used for preparing epoxy floor paint.

[0042] Put the raw materials in the above component A into the dispersing tank, add while stirring, stir and disperse at 1200rpm until the fineness of the slurry is less than 40um, after the powder is added, disperse normally for 30min, then filter and pack.

[0043] Component B:

[0044] 100 parts by mass of epoxy curing agent (WK-6892);

[0045] C component:

[0046] Quartz sand (commercially available 90 orders) 83 parts by mass;

[0047] 17 parts by mass of glas...

Embodiment 2

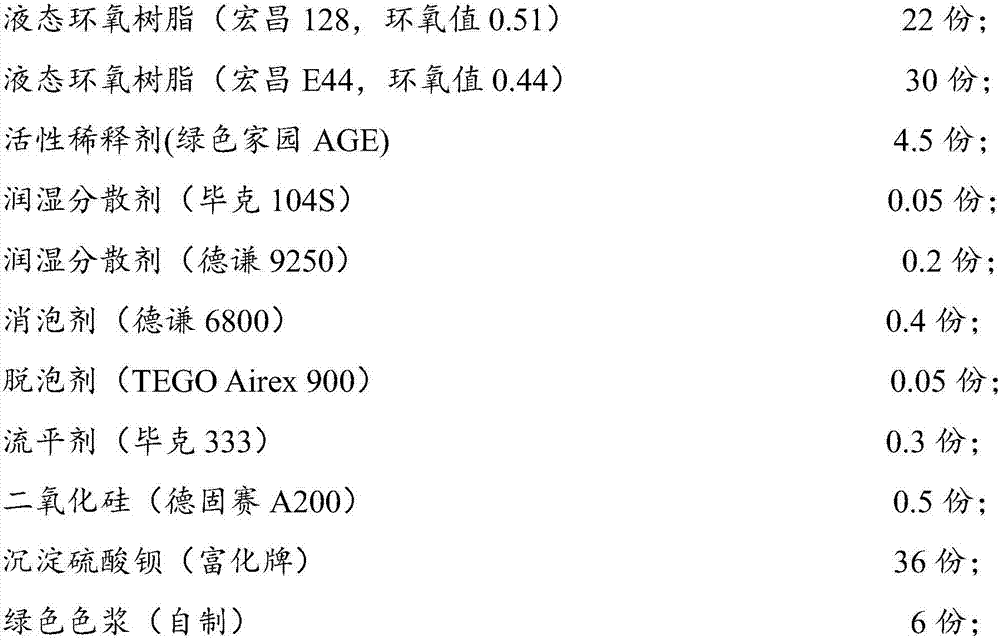

[0050] A kind of epoxy floor paint, each material mass parts are as follows:

[0051] Component A:

[0052]

[0053]

[0054]Wherein, the color paste is prepared as follows: mix 1.5 parts of pigment art green, 0.5 parts of low-viscosity liquid epoxy resin 128, and 0.35 parts of reactive diluent AGE, and then add 0.015 parts of BYK 104S dispersant, and disperse at 1200 rpm. After 30 minutes, the green color paste was obtained by grinding with a three-roller machine, from which 0.5 part was used for preparing epoxy floor paint.

[0055] Put the above raw materials into the dispersing tank, add them while stirring, stir and disperse at 1200rpm until the fineness of the slurry is less than 40um, after the powder is added, disperse normally for 30min, then filter and pack.

[0056] Component B:

[0057] 100 parts of epoxy curing agent (WK-6892);

[0058] C component:

[0059] 28 parts of quartz sand (commercially available 90 orders);

[0060] Glass beads (Zhongke Yali) ...

Embodiment 3

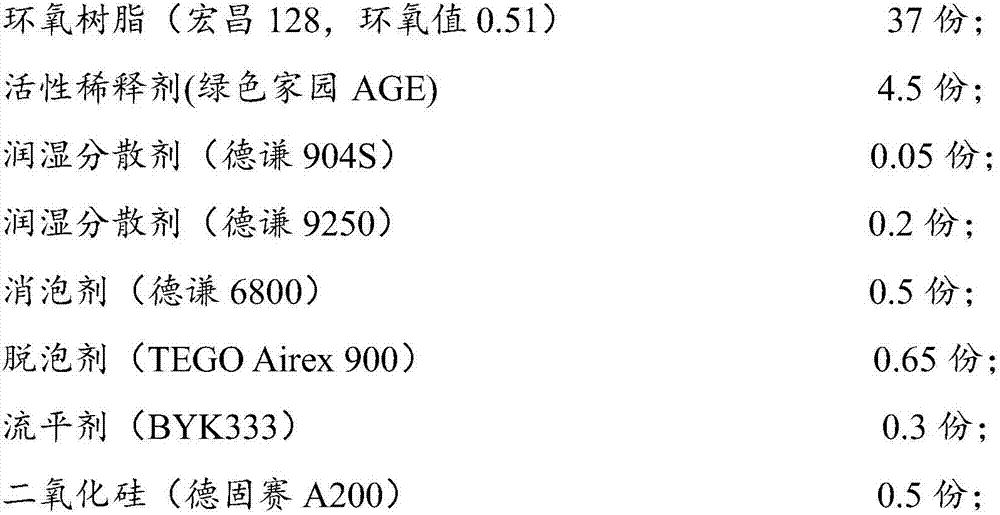

[0064] A kind of epoxy floor paint, each material mass parts are as follows:

[0065] Component A:

[0066]

[0067]

[0068] Wherein, the color paste is prepared as follows: mix 15 parts of pigment art green, 5 parts of low-viscosity liquid epoxy resin 128, and 3.5 parts of reactive diluent AGE, then add 0.15 parts of BYK 104S dispersant, and disperse at 1200 rpm In 30 minutes, the green color paste was obtained by grinding with a three-roller machine, from which 6 parts were used for preparing epoxy floor paint.

[0069] Put the above raw materials into the dispersing tank, add them while stirring, stir and disperse at 1200rpm until the fineness of the slurry is less than 40um, after the powder is added, disperse normally for 30min, then filter and pack.

[0070] Component B:

[0071] 100 parts of epoxy curing agent (2771, air chemical industry);

[0072] C component:

[0073] Quartz sand (commercially available 90 orders) 80 parts;

[0074] Glass beads (Zhongke Y...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com