Method suitable for industrial production of memantine hydrochloride

A technology for memantine hydrochloride and dimethyladamantane, which is applied in the field of medicine, can solve the problems of difficult handling of aluminum reagents, unfavorable industrialization and the like, and achieves the effects of simplified post-processing process, easy post-processing and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

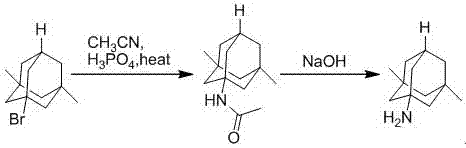

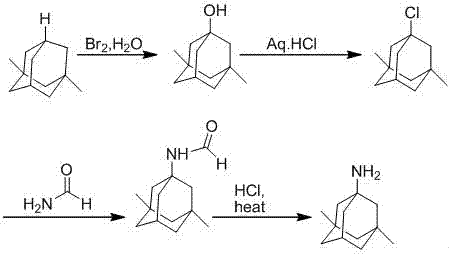

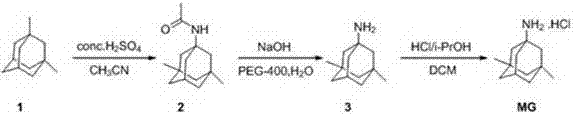

Method used

Image

Examples

Embodiment

[0043] (1) Preparation of 1-acetylamino-3,5-dimethyladamantane

[0044] Add 1,3-dimethyladamantane (300kg) and acetonitrile (1.18kg) into the reaction flask, start stirring, heat in a water bath to 60°C-65°C, pump concentrated sulfuric acid (5.37kg) into the high level tank, add dropwise Concentrated sulfuric acid, the temperature will rise, control the rate of addition, and keep the temperature in the bottle not higher than 75°C. After the dropwise addition, keep the temperature of the reaction bottle at 70°C to 80°C, stir and react for 18 hours, then cool to 20°C to 30°C, slowly pump the reaction solution into a 50L reaction kettle with 20kg of ice water (inner Temperature control 0°C~10°C), after the addition, add dichloromethane (10kg) for extraction, separate the liquid, wash the organic phase (lower layer) with purified water twice, 4kg each time, transfer the dichloromethane to In a distillation flask, concentrate under reduced pressure (the vacuum degree of the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com