Production system and method for methylallyl alcohol

A technology for the production of methallyl alcohol, applied in chemical instruments and methods, preparation of carbon-based compounds, preparation of hydroxyl compounds, etc., can solve problems such as reducing reaction selectivity, reduce polymerization, avoid catalysis, and improve operation The effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

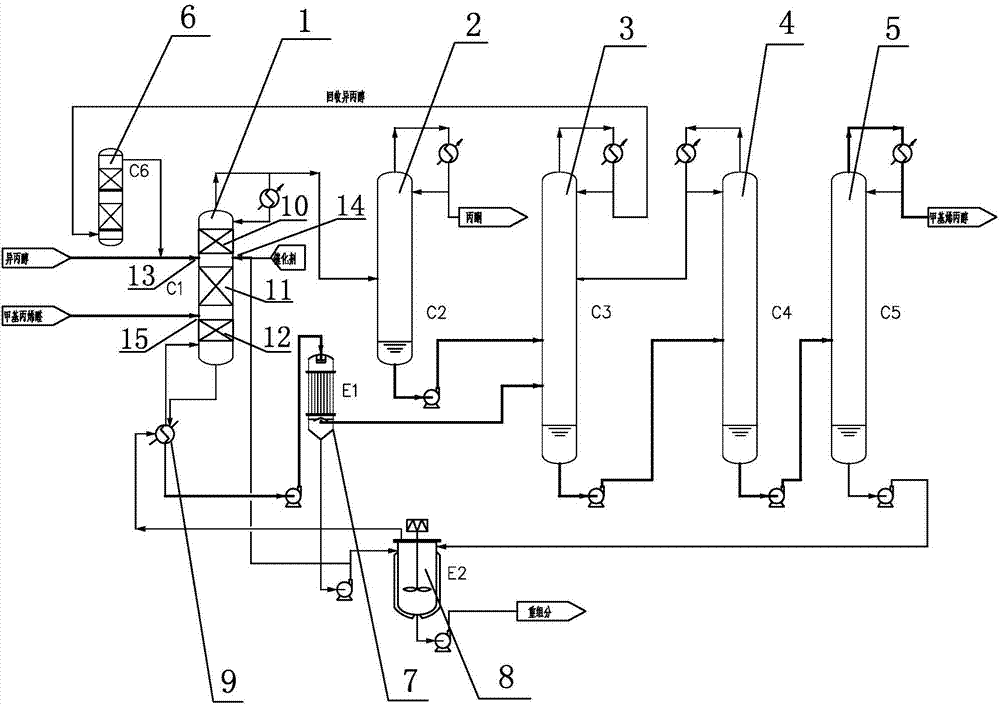

[0036] The method for producing methallyl alcohol using the system of the above specific embodiment 1, such as figure 1 As shown, the specific steps are as follows:

[0037] (1) Feed the fresh isopropanol dehydrated to the moisture content below 50ppm and the recycled isopropanol dehydrated to below 50ppm moisture content by the molecular sieve adsorption tower into the isopropanol inlet 13 of the reactive distillation tower 1; Aluminum propoxide is sent to the catalyst inlet 14 of the reactive distillation tower 1, and the methacrolein is sent to the methacrolein inlet 15 of the reactive distillation tower 1, wherein the molar ratio of methacrolein to isopropanol is controlled to be 5:1; the reactive distillation tower 1 is provided with a rectification section 10, a reaction section 11, and a stripping section 12 from top to bottom. The reactive distillation tower 1 is located between the rectification section 10 and the reaction section 11 The isopropanol inlet 13 and the cat...

Embodiment 2

[0046] Same as the above embodiment 1, the difference lies in:

[0047] In step (1), the feeding molar ratio of methacrolein and isopropanol is controlled to be 0.1:1;

[0048] In step (2), the top pressure of the reactive distillation tower 1 is controlled to 5 kpa, and the temperature of the reaction section 11 of the reactive distillation tower 1 is controlled to 60°C;

[0049] In step (3), the pressure of the falling film evaporator 7 is controlled to 101kPa;

[0050] In step (4), the top pressure of the acetone product tower 2 is controlled to 60kPa, and the temperature is controlled to 40°C;

[0051] In step (5), the top pressure of the isopropanol recovery tower 3 is controlled to 100kPa, and the temperature is controlled to 76°C;

[0052] In step (6), the top pressure of the methallyl alcohol light removal tower 4 is controlled to 101kPa, and the temperature is controlled to 110°C;

[0053] In step (7), the top pressure of the methallyl alcohol product tower 5 is controlled to 101...

Embodiment 3

[0056] Same as the above embodiment 1, the difference lies in:

[0057] In step (1), the feeding molar ratio of methacrolein and isopropanol is controlled to 10:1;

[0058] In step (2), the top pressure of the reactive distillation tower 1 is controlled to 500kpa, and the temperature of the reaction section 11 of the reactive distillation tower 1 is controlled to 80°C;

[0059] In step (3), the pressure of the falling film evaporator 7 is controlled to 115kPa;

[0060] In step (4), the top pressure of the acetone product tower 2 is controlled to 70kPa, and the temperature is controlled to 50°C;

[0061] In step (5), the top pressure of the isopropanol recovery tower 3 is controlled to 800kPa, and the temperature is controlled to 140°C;

[0062] In step (6), the top pressure of the methallyl alcohol light removal tower 4 is controlled to 800 kPa, and the temperature is controlled to 160°C;

[0063] In step (7), the top pressure of the methallyl alcohol product tower 5 is controlled to 700k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com