Method for quickly culturing aerobic granular sludge and sequencing batch reaction device

An aerobic granular sludge, rapid technology, applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve problems such as aerobic granular sludge limitation, achieve low cost, Solve the effects that are not easy to form and take too long to form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those skilled in the art to better understand the technical solution of the present invention, a method for rapidly cultivating aerobic granular sludge and a sequencing batch reaction device provided by the present invention will be described in detail below with reference to the accompanying drawings.

[0024] A method for rapidly cultivating aerobic granular sludge, comprising the following steps:

[0025] (1) Inoculation of activated sludge and pilot plant

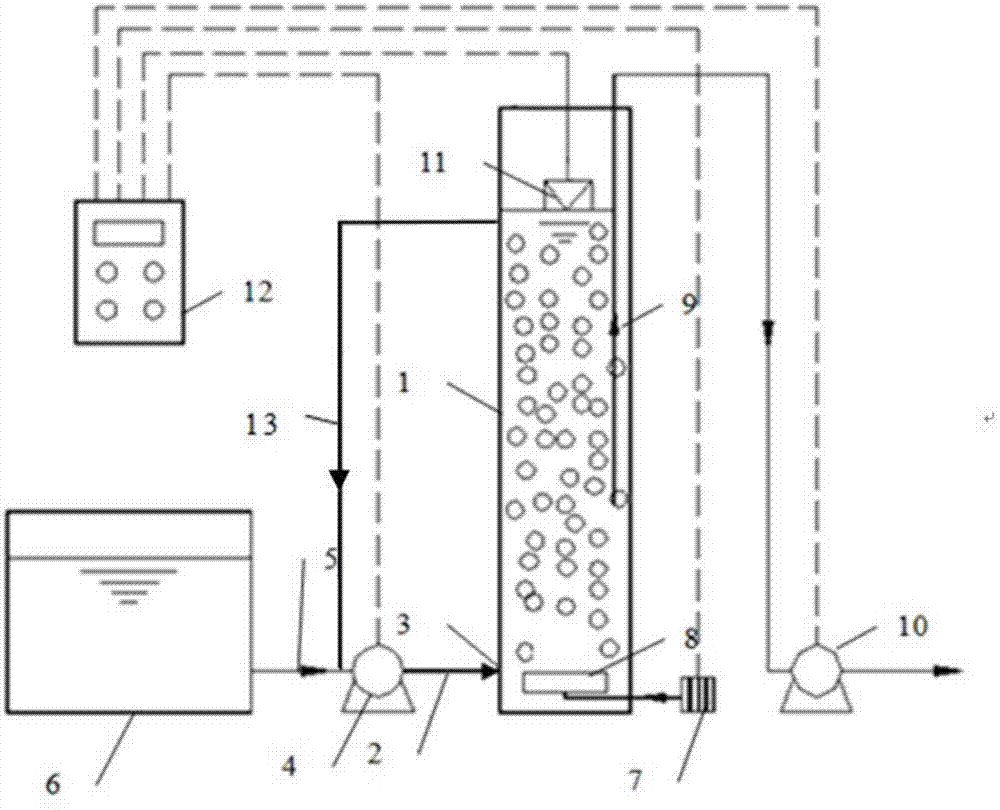

[0026] The anaerobic digestion sludge and aerobic sludge (1:1) from the municipal sewage treatment plant were used as the seed sludge, which was inoculated in the AAASBR reaction device ( figure 1 ), the reactor is cylindrical, with an inner diameter of 0.25m, a height of 2m, and an effective working volume of 85L. The process is carried out at room temperature.

[0027] (2) Water intake method

[0028] In the process of aerobic granular sludge cultivation, the sewage with typical characteris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com