Polyethyleneimine-loaded straw adsorbent as well as preparation method and application thereof

A polyethyleneimine and adsorbent technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the complex and cumbersome preparation methods and processes, and insufficient testing of material structure and chemical stability And evaluation, consumption of more power and energy, etc., to achieve the effect of good hydrodynamic and mechanical strength, good adsorption and removal ability, and good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. A preparation method of straw-loaded polyethyleneimine adsorbent, the steps are as follows:

[0036] 1) Remove the outer skin of the rice straw, cut it into 3mm ring-shaped segments, and let it dry naturally for later use.

[0037] 2) Weigh 1.5g of straw into a 250mL Erlenmeyer flask, add 90mL of 4% PEI solution, immerse and shake at 25°C for 24 hours.

[0038] 3) After the reaction is finished, the straw is washed with water until the pH of the eluate is 9-10.

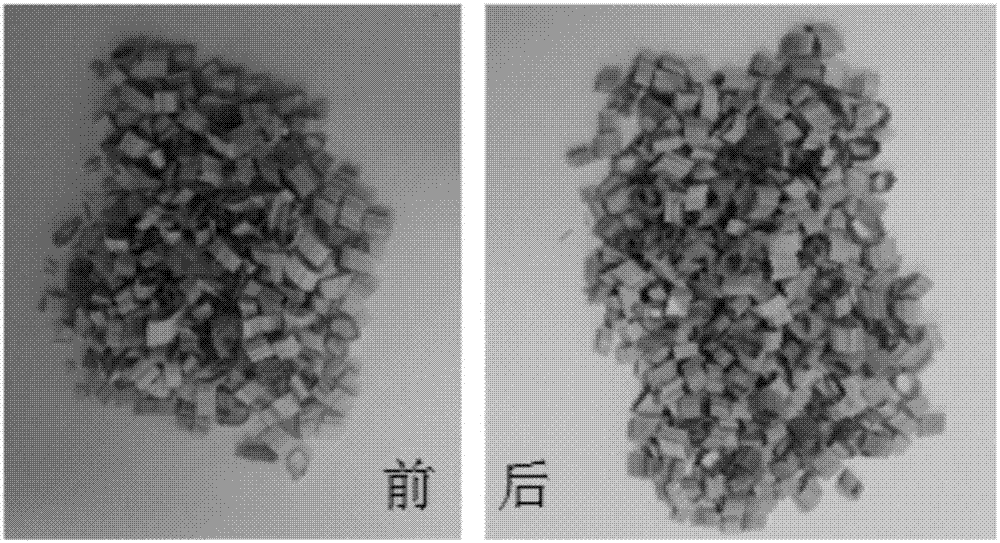

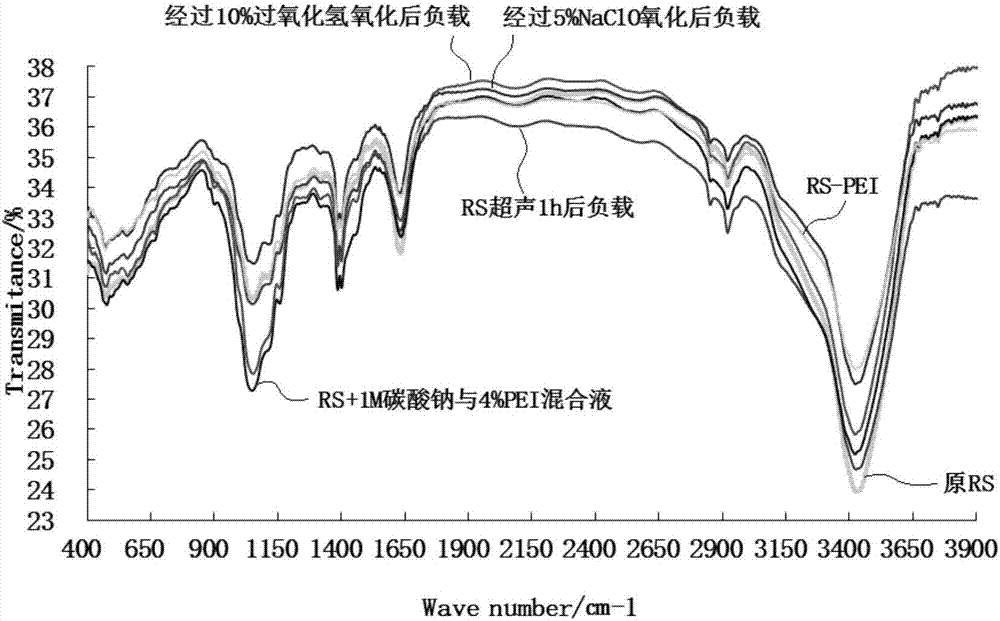

[0039] 4) After draining the water, dry it at 70°C to obtain the composite adsorbent material (RS-PEI), which is straw-loaded polyethyleneimine adsorbent. The difference in morphology of straw before and after preparation is as follows: figure 1 As shown, the color of the loaded RS-PEI is brighter yellow than that of the original RS.

[0040] 2. The preparation method of straw-loaded polyethyleneimine adsorbent, wherein, RS is first ultrasonicated for 1 hour before loading, and the specific process is as ...

Embodiment 2

[0073] A preparation method of a straw-loaded polyethyleneimine adsorbent, the steps are as follows:

[0074] 1) Remove the outer skin of the rice straw, cut it into 3mm ring-shaped segments, and let it dry naturally for later use.

[0075] 2) Weigh 1.5g of straw into a 250mL Erlenmeyer flask, add 90mL of 3% PEI solution, immerse and shake at 25°C for 24 hours.

[0076] 3) After the reaction is finished, the straw is washed with water until the pH of the eluate is 8-9.

[0077] 4) After draining the water, dry it at 50°C to obtain the composite adsorbent material (RS-PEI), which is the straw-loaded polyethyleneimine adsorbent RS-PEI.

[0078] 1) Static adsorption dosage test: Weigh the composite adsorption material RS-PEI prepared by the above method with different masses into a 250mL Erlenmeyer flask, add 50mL of 100mg / L tannic acid adsorption stock solution respectively, shake at 25°C for 12 Hours, the concentration of tannic acid in water after adsorption was detected. T...

Embodiment 3

[0082] The preparation method of RS-PEI is the same as embodiment 1, wherein PEI concentration: 1%~10%, solid-liquid ratio: 50~70 (the solution is all excessive), the material adsorption isotherm that prepares is as follows Figure 7 As shown, it can be seen that the higher the PEI concentration, the stronger the ability of RS-PEI to adsorb gallic acid, and the RS-PEI prepared when the PEI concentration is 6% or higher has basically the same equilibrium adsorption capacity for gallic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com