QLED, preparation method and display apparatus

A dendritic, light-emitting layer technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems affecting QLED light-emitting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

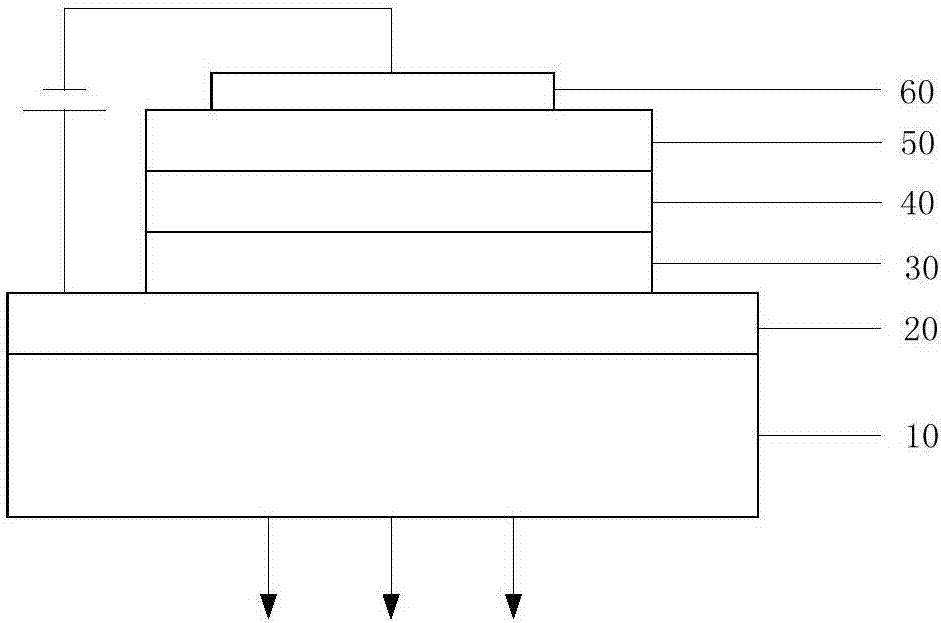

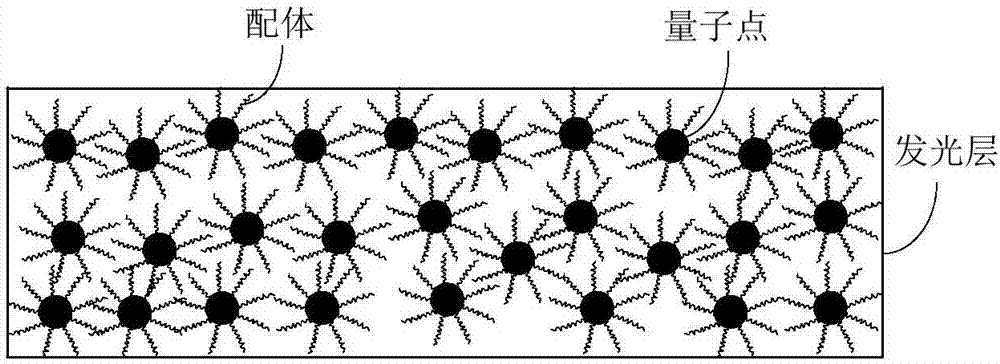

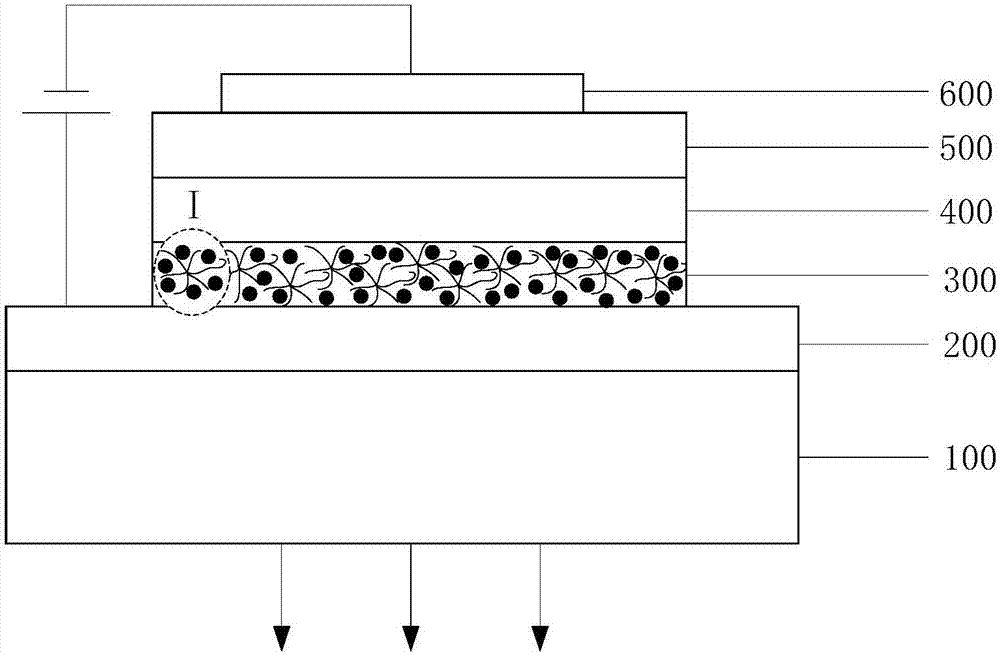

[0021] Embodiment 1 of the present application aims at the problem that the long-chain ligands on the surface of quantum dots in the existing QLED light-emitting layer will affect the light-emitting performance of the QLED, and provides a QLED. image 3 and Figure 4 are respectively a structural schematic diagram of a QLED provided in Embodiment 1 of the present application and image 3 Partial enlarged view of center I. Depend on image 3 and Figure 4 It can be seen that the QLED sequentially includes a substrate 100, an anode 200, a hole transport layer 300, a light emitting layer 400, an electron transport layer 500, and a cathode 600, wherein the light emitting layer 300 includes quantum dots and a dispersant having a dendritic molecular structure, The quantum dots are dispersed between the side chains of the dendrimers.

[0022] In this embodiment, a dispersant having a dendritic molecular structure is used to disperse the quantum dot material, so that the quantum d...

Embodiment 2

[0027] Embodiment 2 of the present application provides a method for preparing the QLED described in Embodiment 1. Figure 5 It is a method flowchart of a method for preparing a QLED provided in Example 2 of the present application. Depend on Figure 5 It can be seen that the method includes:

[0028] Step S201: Spin-coat a hole transport layer, a light emitting layer, and an electron transport layer sequentially on the patterned ITO substrate to form a mixed layer sample, wherein the light emitting layer includes quantum dots and a dispersant with a dendritic molecular structure, so The quantum dots are dispersed between the side chains of the dendrimers.

[0029] Step S202: Evaporating a cathode on the surface of the mixed layer sample.

[0030] In the step S201 of this embodiment, before the hole transport layer is spin-coated, a step of spin-coating the hole injection layer may also be included.

Embodiment 3

[0032] This embodiment provides a method for preparing a QLED, the method comprising:

[0033] Step S301: preparing CdSe / ZnSeS / ZnS quantum dots by hydrothermal method.

[0034]The CdSe / ZnSeS / ZnS quantum dots prepared in this example have a three-layer core-shell structure, the inner core is ZnCdSe, the outer shell is ZnS, and the CdSe / ZnSeS / ZnS quantum dots have strong optical stability. The preparation method is as follows: mix cadmium oxide and amine oxide with a molar ratio of 1:4 in an argon atmosphere, heat to 100°C and keep it warm for 30 minutes, then heat to 220°C to obtain cadmium oleate, and cool the cadmium oleate to room temperature for later use; under anaerobic conditions, dissolve selenium in 5 times the mass of tributyl phosphate, and then add 5 times the mass of octadecene ODE to prepare the selenium solution for later use; quickly add the selenium solution to the cadmium oleate , heated to 260°C and held for 40min. By controlling the holding time (that is, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com