Stable no-light-bath high-efficiency organic solar cell device and preparation method therefor

A technology of solar cells and devices, which is applied in the manufacture of organic semiconductor devices, electric solid devices, semiconductor/solid devices, etc., can solve the problems of unfavorable stable power supply equipment, poor electrical performance, and longer time consumption, etc., to achieve photoelectric conversion efficiency High, maintain flexible processing, simple post-processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

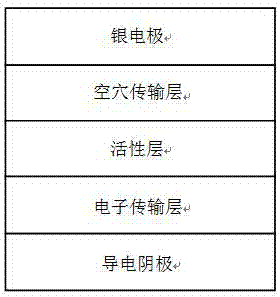

[0033] A stable non-light-bath high-efficiency organic solar cell device, its structure is: ITO / TiO 2 :TOPD(UV+EA) / PTB7-Th:PC 71 BM / MoO 3 / Ag (for the structure schematic diagram see figure 1 ), the specific preparation steps are as follows:

[0034] 1) Conductive substrate pretreatment

[0035] The square resistance is 15Ω, and the patterned transparent conductive substrate ITO is ultrasonically cleaned in deionized water, ethanol, acetone, and isopropanol for 10 minutes, blown dry with nitrogen, and then placed on a hot table to dry, and then UV-ozone treatment to remove Organic matter remains on the surface.

[0036] 2) Preparation of an electron transport layer on a pretreated transparent conductive substrate

[0037] 2a, Preparation of crystalline nano-TiO2 particles

[0038] Using titanium tetrachloride as a precursor, weigh 2.3ml of titanium tetrachloride and 8ml of ethanol in an ice-water bath and mix them thoroughly, transfer the resulting mixture into 40ml of b...

Embodiment 2

[0060] A stable non-light bath high-efficiency organic solar cell device, the specific preparation steps are as follows:

[0061] 1) Conductive substrate pretreatment

[0062] The square resistance is 15Ω, and the patterned transparent conductive substrate ITO is ultrasonically cleaned in deionized water, ethanol, acetone, and isopropanol for 10 minutes, blown dry with nitrogen, and then placed on a hot table to dry, and then UV-ozone treatment to remove Organic matter remains on the surface.

[0063] 2) Preparation of an electron transport layer on a pretreated transparent conductive substrate

[0064] 2a, Preparation of crystalline nano-TiO2 particles

[0065] Using titanium tetrachloride as the precursor, weigh 2ml of titanium tetrachloride and 8ml of ethanol in an ice-water bath and mix thoroughly, transfer the resulting mixture into 40ml of benzyl alcohol, and react at 85°C for 9h; mix 3ml of the reaction product with 27ml Diethyl ether is mixed, precipitated and washe...

Embodiment 3

[0082] A stable non-light bath high-efficiency organic solar cell device, the specific preparation steps are as follows:

[0083] 1) Conductive substrate pretreatment

[0084] The square resistance is 15Ω, and the patterned transparent conductive substrate ITO is ultrasonically cleaned in deionized water, ethanol, acetone, and isopropanol for 10 minutes, blown dry with nitrogen, and then placed on a hot table to dry, and then UV-ozone treatment to remove Organic matter remains on the surface.

[0085] 2) Preparation of an electron transport layer on a pretreated transparent conductive substrate

[0086] 2a, Preparation of crystalline nano-TiO2 particles

[0087] Using titanium tetrachloride as a precursor, weigh 2.5ml of titanium tetrachloride and 8ml of ethanol in an ice-water bath and mix them thoroughly, transfer the resulting mixture into 40ml of benzyl alcohol, and react at 90°C for 9h; mix 3ml of the reaction product with 27ml of diethyl ether were mixed, precipitated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com