Fast dark-field detection method for surface microdefects of large-caliber fused quartz optical element

An optical element and dark field detection technology, applied in the field of engineering optics, can solve the problems of low detection accuracy and efficiency, limited acquisition frame rate, and reduced scanning efficiency, so as to save rapid detection time, improve detection efficiency, and improve detection. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0044] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

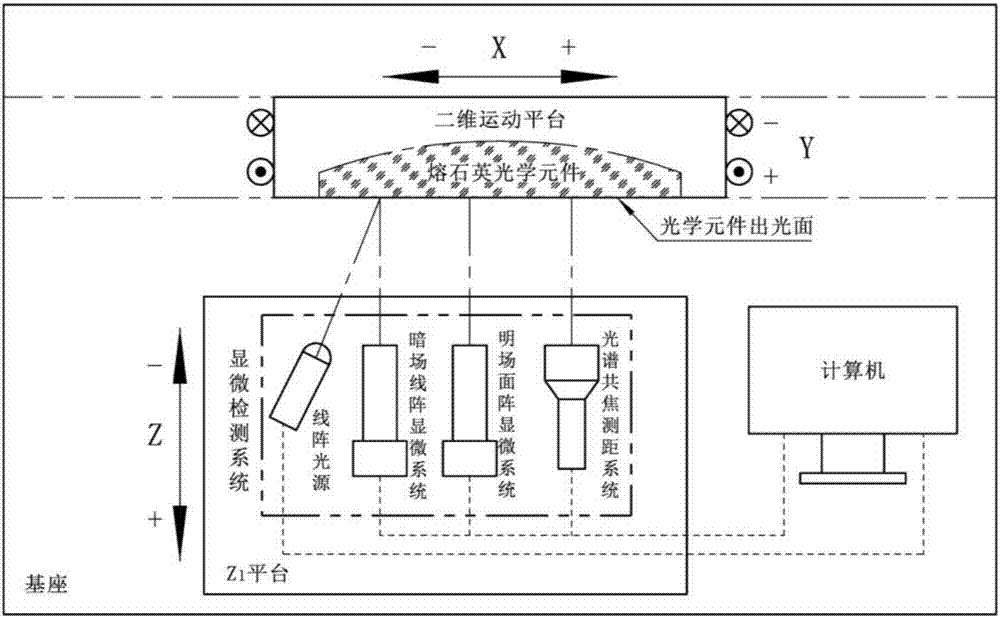

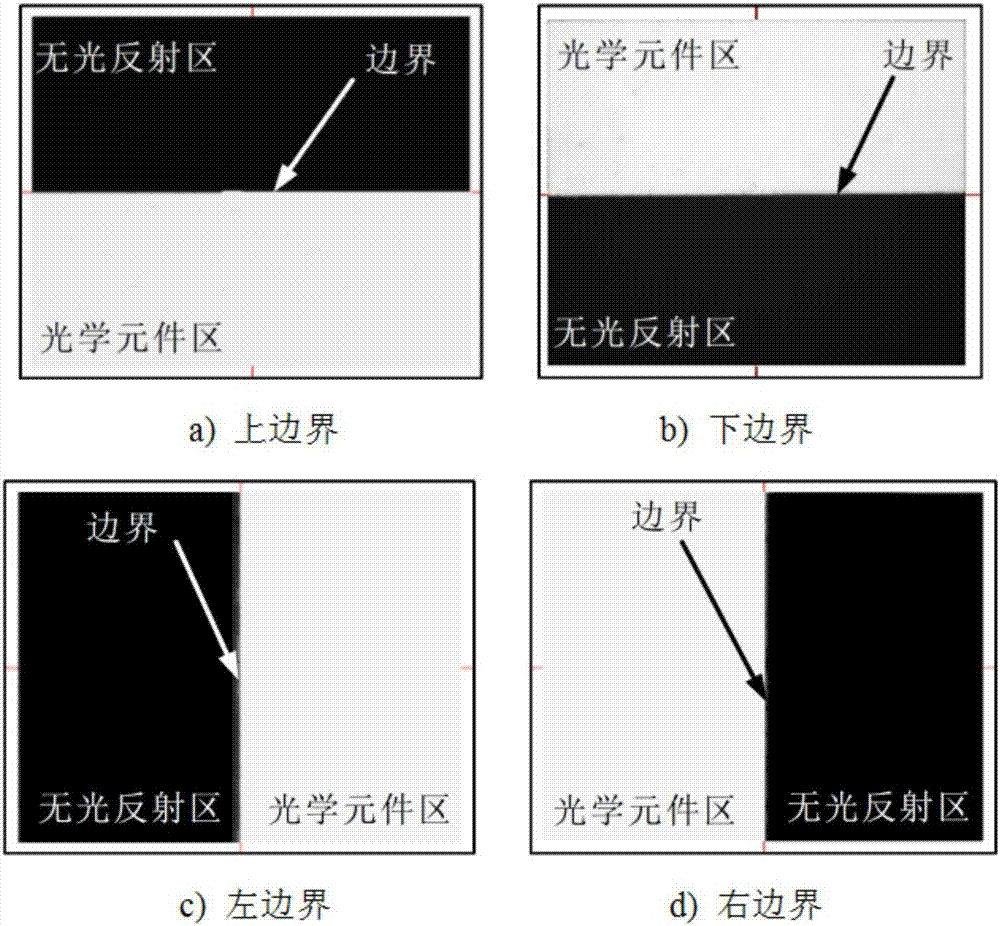

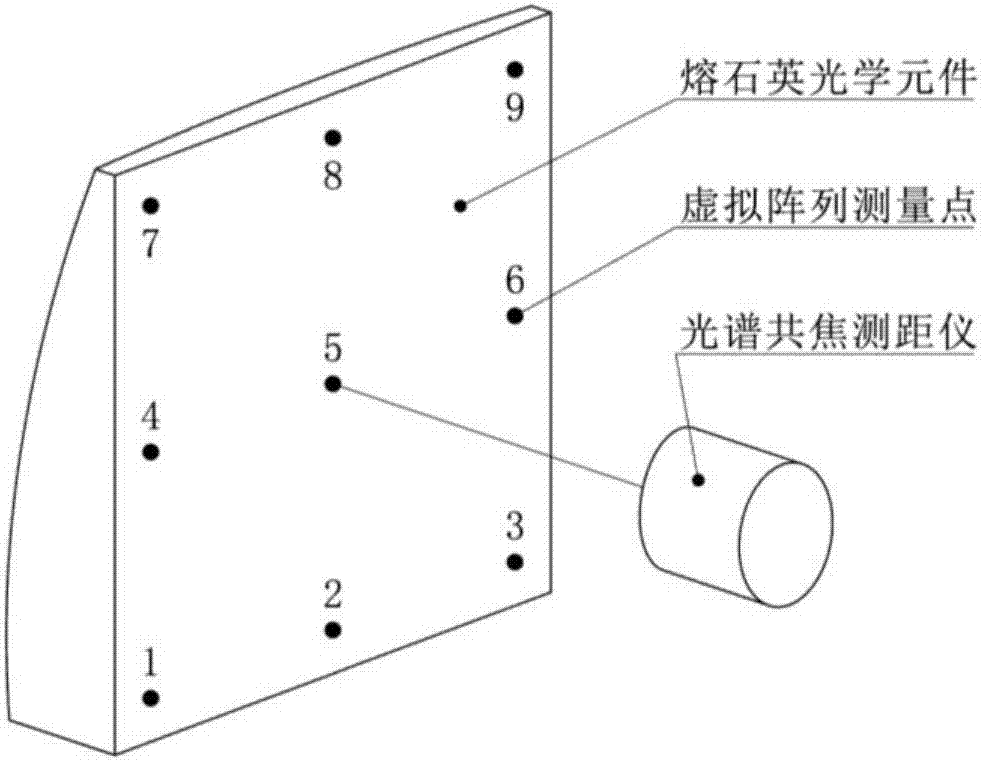

[0045] The invention discloses a fast dark-field detection method for micro-defects on the surface of a large-diameter fused silica optical element. Firstly, a bright-field array CCD microscope system is used to locate the optical element, and the position of the optical element in an absolute coordinate system is determined, and then the spectral The confocal distance measuring system determines the light surface equation of the optical element irradiated by strong laser light. Finally, the dark field linear array CCD microscope system is used to scan the surface of the precisely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com