Uniform temperature control type aluminum roll annealing furnace

An annealing furnace, uniform technology, applied in furnaces, heat treatment furnaces, furnace types, etc., can solve problems such as smoke pollution, environmental heat pollution, etc., achieve the effect of reducing operating steps, reducing auxiliary devices, and uniform and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

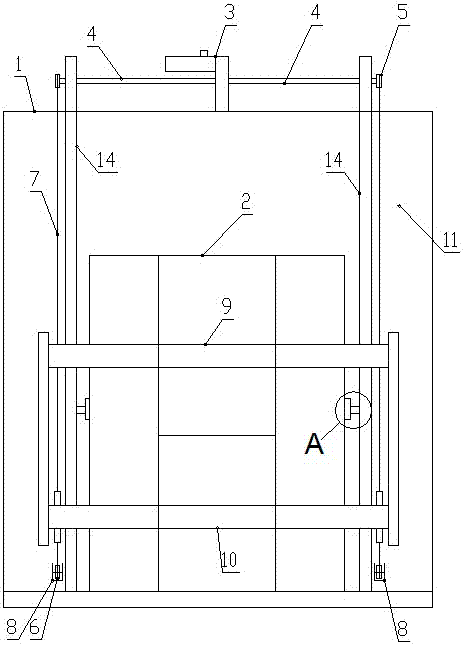

[0039] In the present invention, take the end where the furnace door 2 is located as the front end of the annealing furnace.

[0040] like Figure 1 to Figure 7 As shown, the aluminum coil annealing furnace with uniform temperature control of the present invention includes a furnace body 1 and an electric control device 21. A furnace is provided in the furnace body 1, and a door opening for aluminum coils to enter and exit is provided on the front wall 11 of the furnace body 1. There is a furnace door 2 for closing the door opening from front to back; the door opening is figure 1 The center is blocked by the furnace door 2, and the hearth is a conventional structure, which is also blocked by the furnace door 2 and the furnace body 1, so the figure is not shown. The electric control device 21 preferably adopts PLC, and certainly also can adopt single-chip microcomputer or integrated circuit. The electric control device 21 can be installed on the furnace body 1 , or can be ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com