Graphene-waterborne epoxy high-dispersion system and synthetic method thereof

A water-based epoxy and synthesis method technology, applied in epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve problems such as pending research, heavy steel connection workload, structural safety hazards, etc., to reduce usage and increase market share. Competitiveness and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

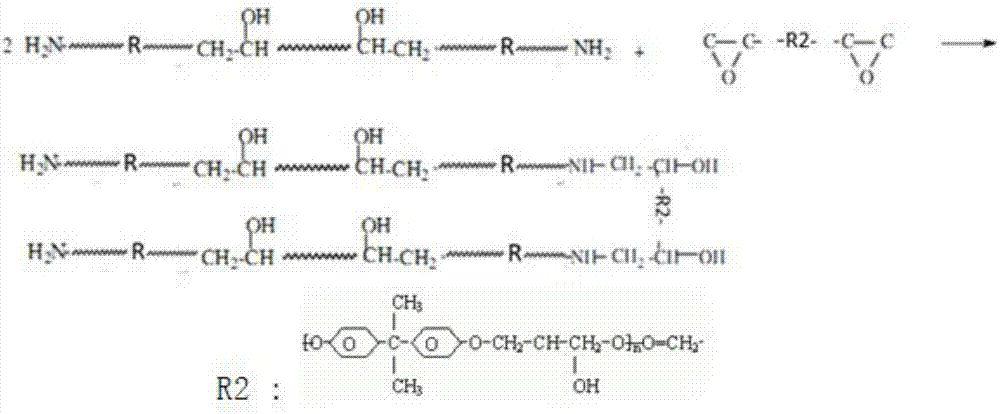

[0053] According to the molar ratio of 1:2.0, take polyethylene glycol diglycidyl ether and triethylenetetramine and mix them uniformly, then carry out addition chain extension reaction at 65°C for 3 hours, so as to introduce hydrophilic groups on the primary amino groups to obtain terminal Amino hydrophilic polyether segment (see figure 1 ). According to the molar ratio of 2.0:1, take the amino-terminated hydrophilic polyether segment and E51 epoxy resin for addition and chain extension reaction at 65°C for 4 hours to obtain the amino-terminated long-chain nonionic self-emulsifying epoxy curing agent (see figure 2 ).

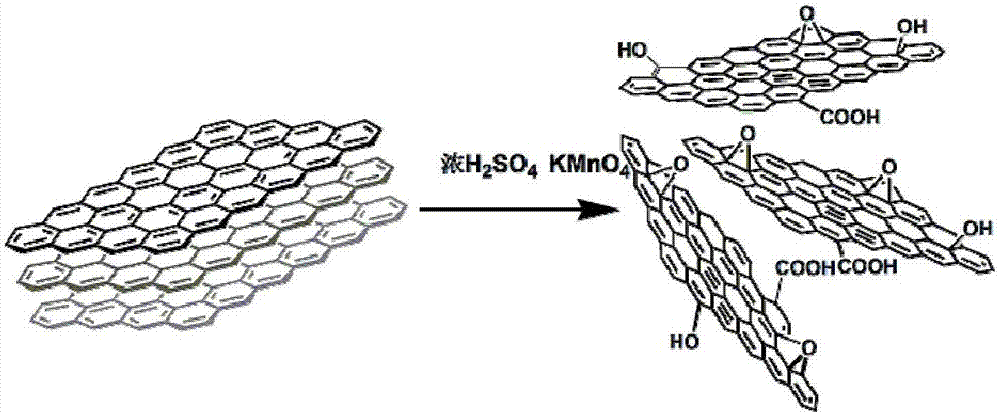

[0054] Ultrasound-assisted Hummers method was used to prepare low-oxidation graphene, such as image 3 As shown, the specific steps are as follows: (1) according to the proportioning by weight, 100 parts by weight of 98% vitriol oil, 0.8 parts by weight of graphite powder and 0.3 parts by weight of sodium nitrate are placed in a beaker, and after stirring fo...

Embodiment 2

[0059] According to the molar ratio of 1:2.1, take polyethylene glycol diglycidyl ether and isophorone diamine and mix them evenly, then carry out addition chain extension reaction at 60°C for 4 hours, so as to introduce hydrophilic groups on the primary amino group An amino-terminated hydrophilic polyether segment is obtained. According to the molar ratio of 2.1:1, the amino-terminated hydrophilic polyether segment and the E44 epoxy resin were subjected to addition chain extension reaction at 60°C for 3 hours to obtain an amino-terminated long-chain nonionic self-emulsifying epoxy curing agent.

[0060] Adopt ultrasonic-assisted Hummers method to prepare low-oxidation degree graphene, concrete steps are as follows: (1) according to the proportioning by weight, get the 98% vitriol oil of 100 parts by weight, 1.0 parts by weight of graphite powder and 0.5 parts by weight of sodium nitrate to be placed in beaker one, in After stirring for 1 hour at 2°C, add 4 parts by weight of ...

Embodiment 3

[0065] According to the molar ratio of 1:2.05, take triethylene glycol diglycidyl ether and p-xylylenediamine and mix them evenly, then carry out addition chain extension reaction at 63°C for 3.5 hours, so as to introduce hydrophilic groups on the primary amino groups An amino-terminated hydrophilic polyether segment is obtained. According to the molar ratio of 2.05:1, the amino-terminated hydrophilic polyether segment and the E20 epoxy resin were subjected to addition chain extension reaction at 63°C for 3.5 hours to obtain an amino-terminated long-chain nonionic self-emulsifying epoxy curing agent.

[0066] Adopt ultrasonic-assisted Hummers method to prepare graphene with low degree of oxidation, concrete steps are as follows: (1) according to the proportioning by weight, get 98% vitriol oil of 100 weight parts, 1.2 weight parts graphite powder and 0.7 weight parts sodium nitrate are placed in beaker one, in After stirring at 0°C for 1 hour, add 6 parts by weight of potassiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com