Method for preparation of levulinate by solid acid catalyst catalyzed sugar conversion

A technology of catalyst catalyzing sugar and solid acid catalyst, applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of poor catalytic effect, low catalyst loading rate, etc. Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

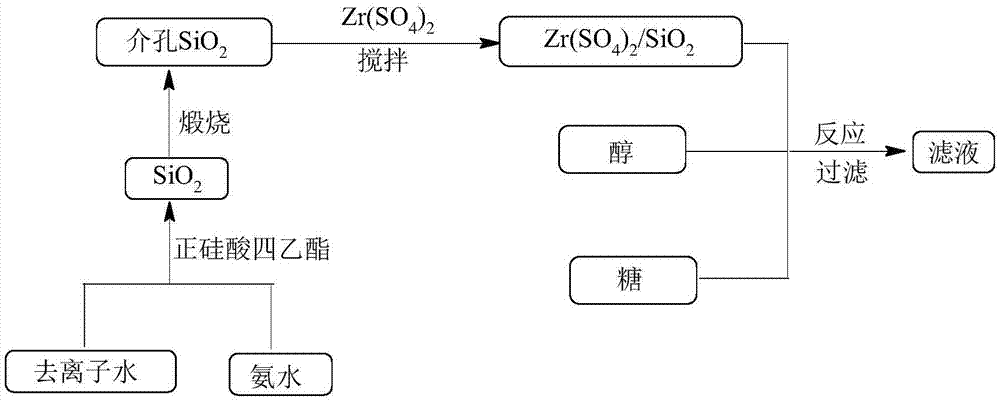

[0023] In the method for preparing levulinic acid ester of the present invention, sugar, catalyst, alcohol and cyclohexane are placed in a reaction kettle, reacted at a set temperature and a set time, and after the reaction is completed, the filtrate is taken out and filtered to obtain levulinic acid acid ester solution.

[0024] The concrete steps of preparation levulinate method:

[0025] a, sugar, solid acid catalyst, alcohol and hexanaphthene are placed in the reaction kettle and stirred evenly;

[0026] b. Seal the reaction kettle, set the temperature, and the rotation speed is 300r / min. When the temperature reaches the set value, it will react under the condition of the set time;

[0027] c. After the reaction time is up, quickly cool down to room temperature, open the reaction kettle, take out the filtrate of the product, and filter to obtain the levulinic acid ester solution.

[0028] The sugar is any one of glucose, fructose or sucrose.

[0029] Described alcohol i...

Embodiment 1

[0035] Get 0.5g solid acid catalyst Zr(SO 4 ) 2 / SiO 2 , 1.0 g of glucose, 30 ml of methanol and 10 ml of cyclohexane were placed in a reaction kettle at a reaction temperature of 200° C. for 30 minutes. After the reaction, the reactants were taken out and filtered to obtain a filtrate containing methyl levulinate. At this time, the yield of methyl levulinate was 35.82%.

Embodiment 2

[0037] Get 0.4g solid acid catalyst Zr(SO 4 ) 2 / SiO 2 , 2.0 g of fructose, 32 ml of absolute ethanol and 15 ml of cyclohexane were placed in a reaction kettle at a reaction temperature of 190° C. and reacted for 40 minutes. After the reaction was completed, the reactant was taken out and filtered to obtain a filtrate containing ethyl levulinate. At this time, the yield of ethyl levulinate was 41.12%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com