Resourceful treatment method for oil and gas field well drilling oily cuttings

A processing method and recycling technology, which is applied in the field of resource processing of oily drill cuttings in oil and gas fields, can solve the problems of high cost, complicated process, unbearable operating cost, etc., and achieve the effect of low processing cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

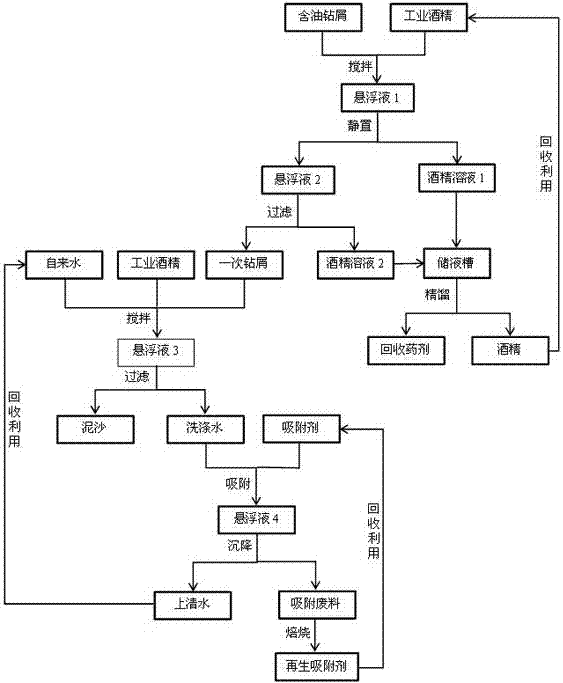

Image

Examples

Embodiment 1

[0025] Weigh 100g of oily drilling cuttings from oil and gas fields, put them into 300mL of industrial alcohol, and stir at a temperature of 45°C and a stirring speed of 400r / min for 30min to obtain suspension 1, and after standing for 30min, obtain suspension 2 and alcohol solution 1, suspension 2 After filtration, the primary drilling cuttings and alcohol solution 2 are obtained; the alcohol solution 1 and the alcohol solution 2 are transferred to the liquid storage tank and rectified and separated at a temperature of 85°C to obtain recovered pharmaceuticals and alcohol, and the alcohol is recycled; the primary drilling cuttings are mixed with 300mL tap water Stir and mix with 20mL industrial alcohol at 85°C to obtain a suspension 3, which is filtered to obtain sediment and washing water, and the washing water interacts with the adsorbent MgO to obtain a suspension 4, which is subjected to sedimentation treatment The supernatant water and MgO adsorption waste are obtained, th...

Embodiment 2

[0027] Weigh 120g of drilling cuttings from oil and gas fields and put them into 350mL of industrial alcohol. Stir at a temperature of 30°C and a stirring speed of 500r / min for 35 minutes to obtain suspension 1. After standing for 40 minutes, suspension 2 and alcohol solution 1 are obtained. Suspension 2 is obtained by filtration. Primary drilling cuttings and alcohol solution 2; alcohol solutions 1 and 2 are transferred to the liquid storage tank and rectified and separated at a temperature of 85°C to obtain recovered chemicals and alcohol, and the alcohol is recycled; primary drilling cuttings are mixed with 350mL tap water and 25mL industrial alcohol at 90 After stirring and mixing at ℃, the suspension 3 is obtained. The suspension 3 is filtered to obtain sediment and washing water. The washing water interacts with the adsorbent activated carbon to obtain the suspension 4. The suspension 4 is settled to obtain supernatant water and silica gel adsorption. Waste materials and ...

Embodiment 3

[0029] Weigh 110g of oil and gas field drilling cuttings and put them into 260mL of industrial alcohol at a temperature of 25°C and a stirring speed of 600r / min for 40 minutes to obtain a suspension 1. After standing for 50 minutes, a suspension 2 and an alcohol solution 1 are obtained. The suspension 2 is obtained by filtration. Primary drilling cuttings and alcohol solution 2; alcohol solutions 1 and 2 are transferred to the liquid storage tank and rectified and separated at a temperature of 80°C to obtain recovered chemicals and alcohol, and the alcohol is recycled; primary drilling cuttings are mixed with 250mL tap water and 15mL industrial alcohol at 80 After stirring and mixing at ℃, the suspension 3 is obtained. The suspension 3 is filtered to obtain sediment and washing water. The washing water interacts with the adsorbent molecular sieve to obtain the suspension 4. The suspension 4 is settled to obtain supernatant water and molecular sieve adsorption. The waste and sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com