Semisolid combined extrusion casting forming method of magnesium alloy casting

A composite extrusion and composite molding technology, which is applied in the field of semi-solid composite extrusion casting of magnesium alloy castings, can solve problems such as billet surface oxidation, rheological deformation, quantitative transportation, difficulty in transfer, and the addition of special equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be further described below in conjunction with accompanying drawing:

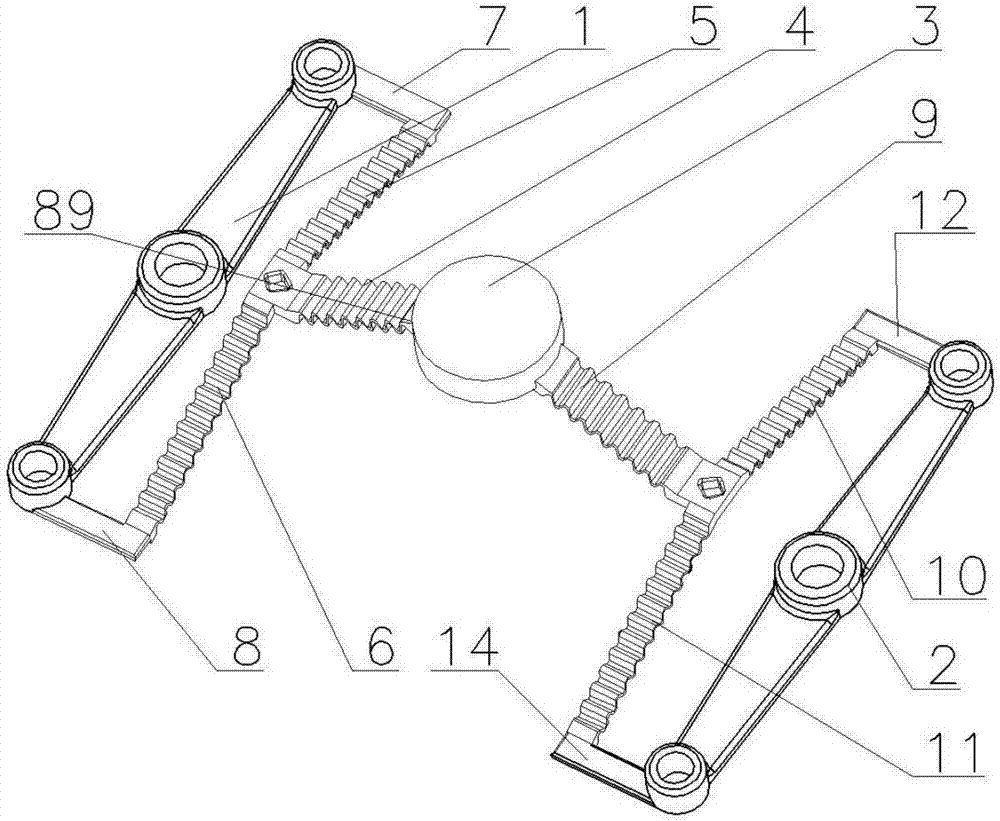

[0073] figure 1 As shown, it is a casting structure diagram with sprues. The middle position of the molded casting 89 is the material cake 3, and the left side of the material cake 3 is connected to the left self-stirring sprue 4, and the left self-stirring sprue 4 is connected to the first self-stirring sprue respectively. The runner 5 and the second self-stirring sub-runner 6 are connected, the first self-stirring sub-runner 5 is connected to the first ingate 7, the second self-stirring sub-runner 6 is connected to the second ingate 8, and the first self-stirring sub-runner 6 is connected to the second ingate 8. The ingate 7 and the second ingate 8 are connected to the left casting 1; the right side of the material cake 3 is connected to the right self-stirring sprue 9, and the right self-stirring sprue 9 is connected to the third self-stirring sub-runner 10 and the third...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com