Water permeable material and preparation method thereof

A technology of water-permeable materials and filter materials, which is applied in the field of water-permeable materials and their preparation, can solve problems affecting the purification of the ecological environment, and achieve the effects of promoting environmental protection, reducing energy consumption, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

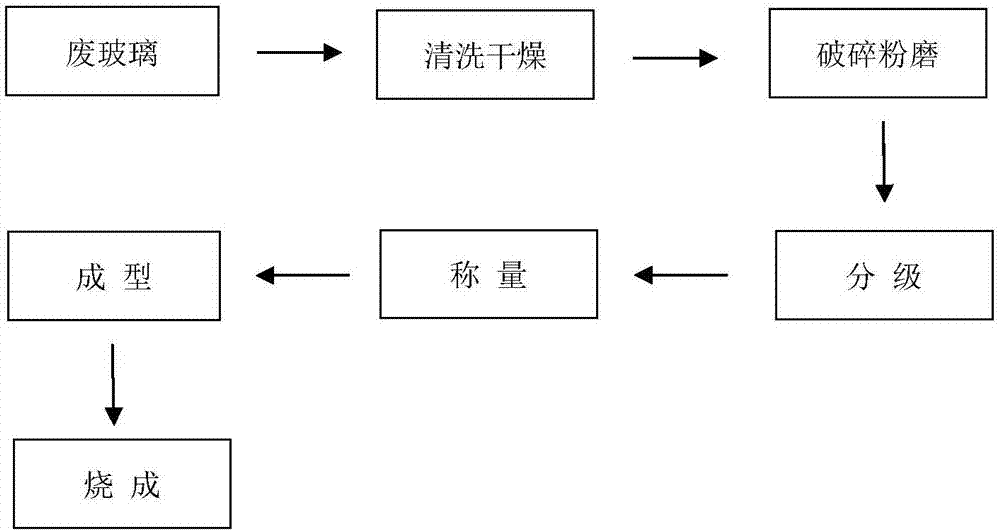

Method used

Image

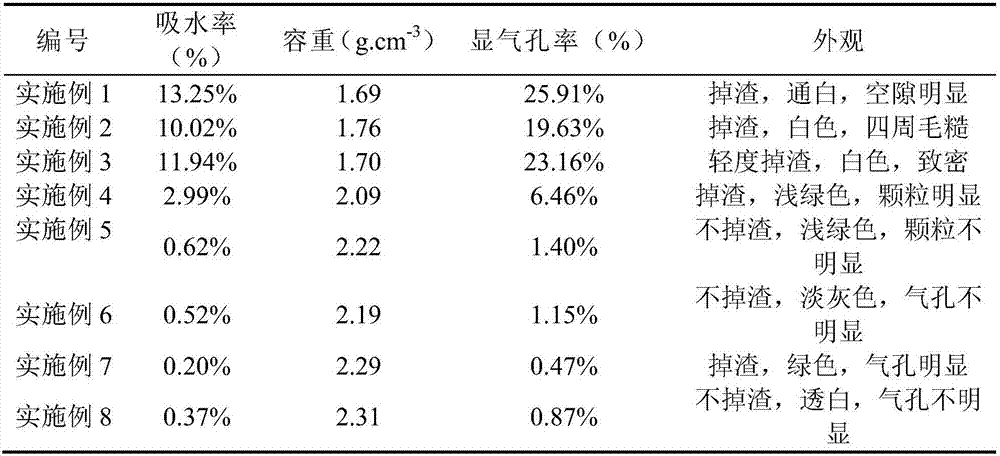

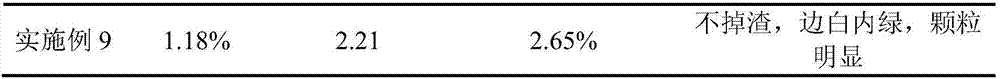

Examples

Embodiment 1

[0027] (1) Wash and dry the collected waste glass, crush and grind it, then sieve and classify it, and select 8-20 mesh glass particles;

[0028] (2) Weigh 100g of the 8-20 mesh glass particles in step (1) and put them into a cube iron mold, and pile them up naturally;

[0029] (3) Put the mold equipped with glass particles in step (2) into a firing furnace for firing at 720° C. for 120 minutes, and cool naturally to room temperature to obtain a cube-shaped water-permeable filter material.

Embodiment 2

[0031] (1) Wash and dry the collected waste glass, crush and grind it, then sieve and classify it, and select 20-40 mesh glass particles;

[0032] (2) Weigh 100g of 20-40 mesh glass particles in step (1) and put them into a cube iron mold, and pile them up naturally;

[0033] (3) Put the mold equipped with glass particles in the step (2) into a firing furnace for firing at 720° C. for 80 minutes, and cool naturally to room temperature to obtain a cube-shaped water-permeable filter material.

Embodiment 3

[0035] (1) Wash and dry the collected waste glass, crush and grind it, then sieve and classify it, and select 40-80 mesh glass particles;

[0036] (2) Weigh 100g of 40-80 mesh glass particles in step (1) and put them into a cube iron mold, and pile them up naturally;

[0037] (3) Put the mold equipped with glass particles in step (2) into a firing furnace for firing at 720° C. for 40 minutes, and cool naturally to room temperature to obtain a cube-shaped water-permeable filter material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com