Low-water-absorption and flame-retarding nylon 66 composition and preparation method thereof

A technology of flame retardant nylon and low water absorption, applied in the field of low water absorption flame retardant nylon 66 composition and its preparation, to achieve good flame retardancy, dimensional stability, and high barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

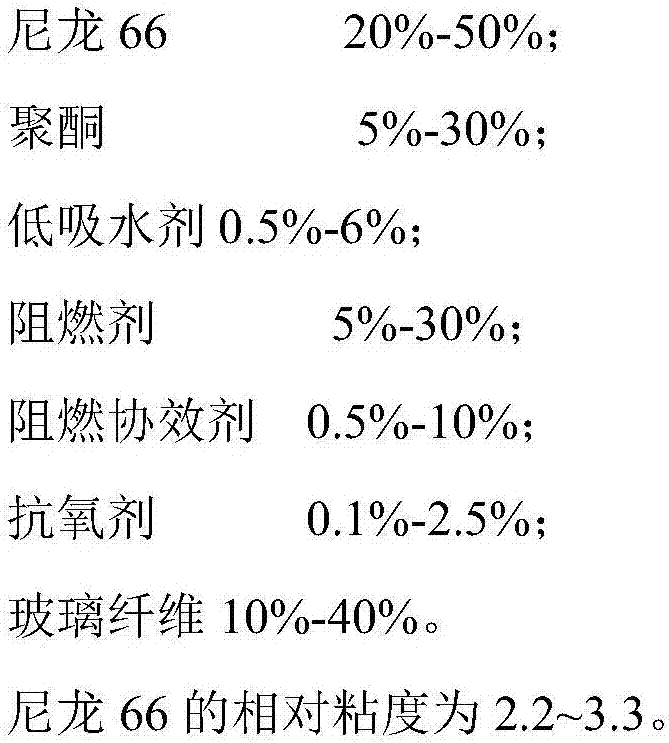

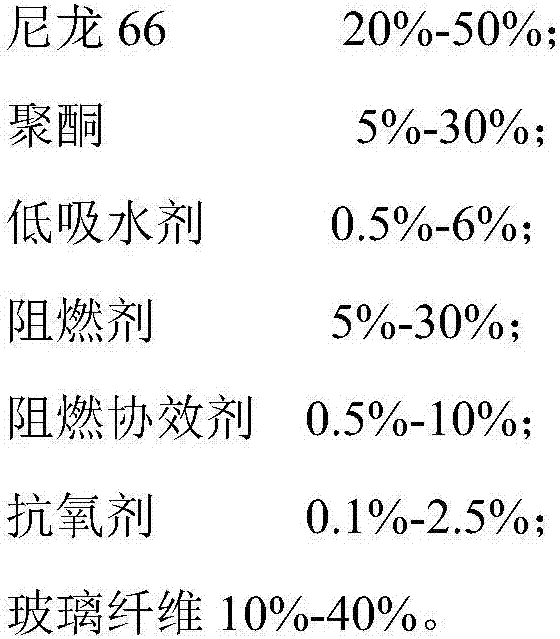

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of above-mentioned a kind of low water-absorbing flame-retardant nylon 66 composition, comprises the following steps:

[0042]1) weighing each component except the glass fiber in proportion, stirring and mixing to obtain a premix;

[0043] 2) Add the premixed material to the main feeding port of the twin-screw extruder, add glass fiber from the side feeding port, extrude, and granulate to obtain a low water absorption flame-retardant nylon 66 composition.

[0044] Preferably, the twin-screw extruder is a toothed co-rotating parallel twin-screw extruder with an aspect ratio ≥ 32:1; the temperature range of each zone of the twin-screw extruder is 245°C to 305°C; further preferably, the twin-screw extruder The aspect ratio of the screw extruder is (36-40):1.

Embodiment 1

[0047] The following raw materials are used:

[0048]

[0049] Put the components other than the glass fiber into the high-speed mixer according to the weight percentage, and stir for 2-5 minutes at room temperature and 60 rpm to prepare the premix; select the tooth with an aspect ratio of 36:1 Joint-type co-rotating parallel twin-screw extruder, the temperature range of each zone is 245-305°C, the premixed material is fed into the extruder through the main feed port of the twin-screw extruder, and the glass fiber is extruded through the twin-screw extruder at the same time The side feeding port of the extruder is fed into the extruder, and the low water absorption and flame retardant nylon 66 composition is obtained through drawing, water cooling, dehumidification, and pelletizing.

Embodiment 2

[0051] The following raw materials are used:

[0052]

[0053] Put the components other than the glass fiber into the high-speed mixer according to the weight percentage, and stir for 2-5 minutes at room temperature and 60 rpm to prepare the premix; select the tooth with an aspect ratio of 36:1 Joint-type co-rotating parallel twin-screw extruder, the temperature range of each zone is 245-305°C, the premixed material is fed into the extruder through the main feed port of the twin-screw extruder, and the glass fiber is extruded through the twin-screw extruder at the same time The side feeding port of the extruder is fed into the extruder, and the low water absorption and flame retardant nylon 66 composition is obtained through drawing, water cooling, dehumidification, and pelletizing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com