Fabrication method of nanowire structure

A production method and nanowire technology, which are applied in nanotechnology, semiconductor devices, electrical components, etc., to achieve the effect of small damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

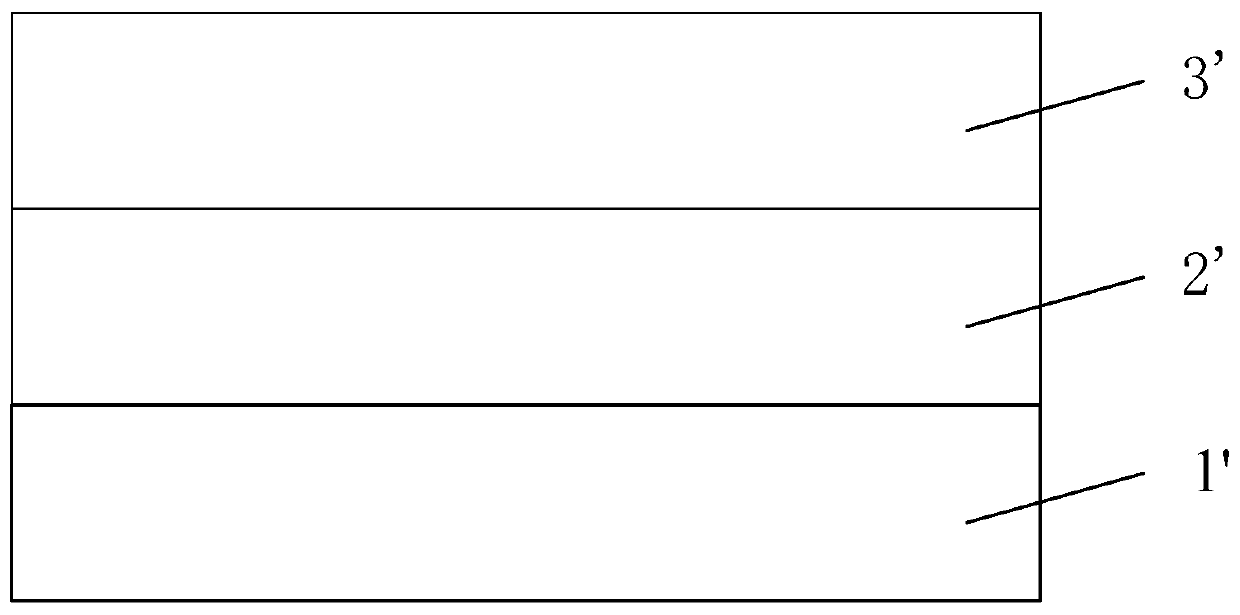

[0089] The nanowire fabrication process includes:

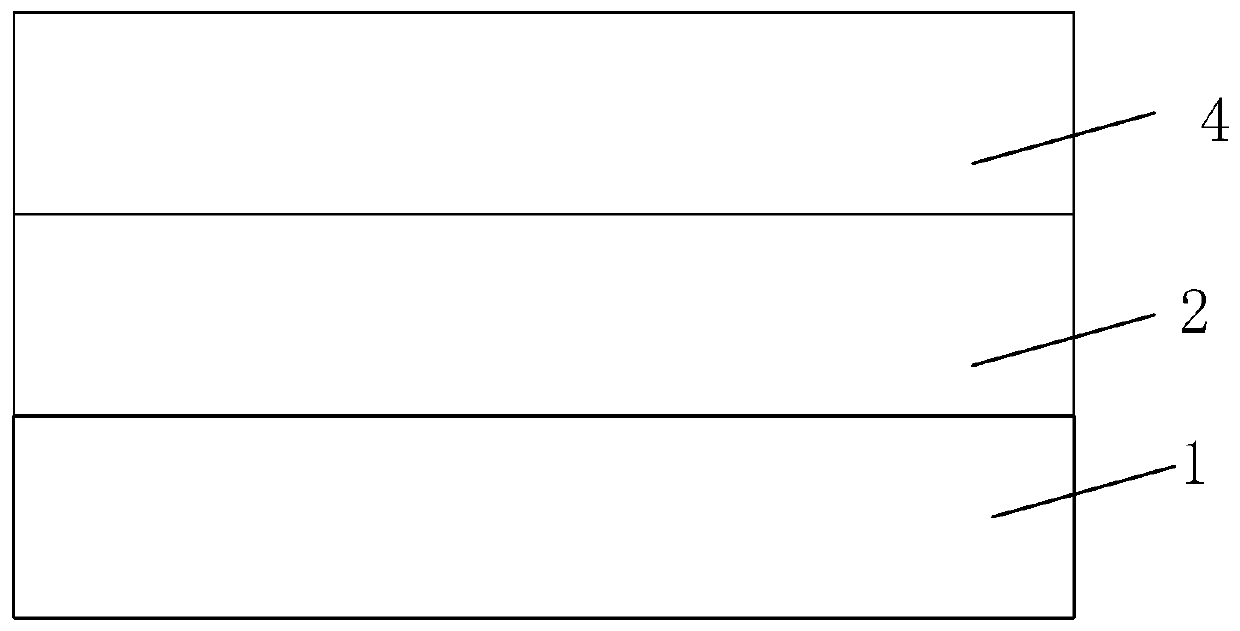

[0090] Step S1, providing a substrate, which is a silicon substrate, and sequentially epitaxially growing germanium and vapor-phase-depositing silicon nitride on the above-mentioned substrate, and then forming a first semiconductor material layer with a thickness of 40 nm and a mask with a thickness of 40 nm. The film layer is etched through the mask layer, the first semiconductor material layer and the silicon substrate at a certain depth by plasma anisotropic etching to form an island structure with steep side walls. The width of the island structure is 100nm. Each island structure includes The first semiconductor material part and the mask part.

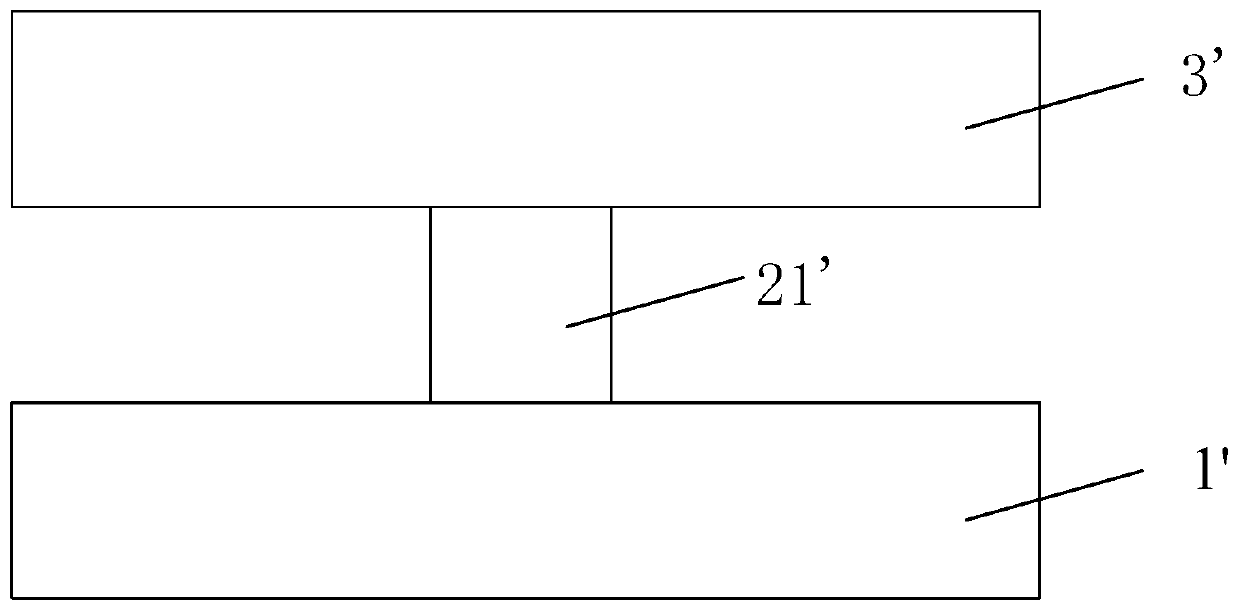

[0091] Step S2, oxidizing the first semiconductor material part and the substrate in each island structure, so that the surface part of the first semiconductor material part forms the first surface layer 20, that is, the germanium oxide layer, and the surface part of the substrat...

Embodiment 2

[0097] The difference from Example 1 is that

[0098] In step S2, the gas pressure in the plasma oxidation device is controlled to be 5mT, the radio frequency power of the plasma oxidation device is controlled to be 100W, the temperature in the plasma oxidation device is controlled to be 100°C, and oxygen is introduced into the device, In addition, the flow rate of oxygen is 5 sccm, and the working time of the radio frequency source for controlling the plasma oxidation device is 10 s.

[0099] Step S3, using a dry etching device to etch and remove the above-mentioned first surface layer, that is, putting the structure processed in step S2 into a dry etching device, specifically, controlling the gas pressure in the above-mentioned etching device to be 5 mT, and controlling The radio frequency power of the above-mentioned etching device is 50W, the temperature in the device is controlled to be 100°C, the etching gas HCl and the carrier water vapor are passed into the device, and...

Embodiment 3

[0101] The difference from Example 1 is that

[0102] In step S2, the gas pressure in the plasma oxidation device is controlled to be 100mT, the radio frequency power of the plasma oxidation device is controlled to be 100W, the temperature in the plasma oxidation device is controlled to be 150°C, and oxygen is introduced into the device, And the flow rate of oxygen is 200 sccm, and the working time of the radio frequency source for controlling the plasma oxidation device is 2s.

[0103] In step S3, a dry etching device is used to etch and remove the above-mentioned first surface layer, that is, the structure processed in step S2 is put into a dry etching device, specifically, the gas pressure in the above-mentioned etching device is controlled to be 100 mT, Control the radio frequency power of the above-mentioned etching device to 100W, control the temperature in the device to 150°C, pass the etching gas HCl and carrier water vapor into the device, and the flow rate of HCl is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com