Full-intelligent scale-preventing and scale-removing alloy and preparation method thereof

An anti-scaling, descaling and alloying technology, applied in the field of alloy materials, can solve problems such as pollution and poor safety performance, and achieve the effects of better structure, less loss of electrons, and reasonable and safe composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

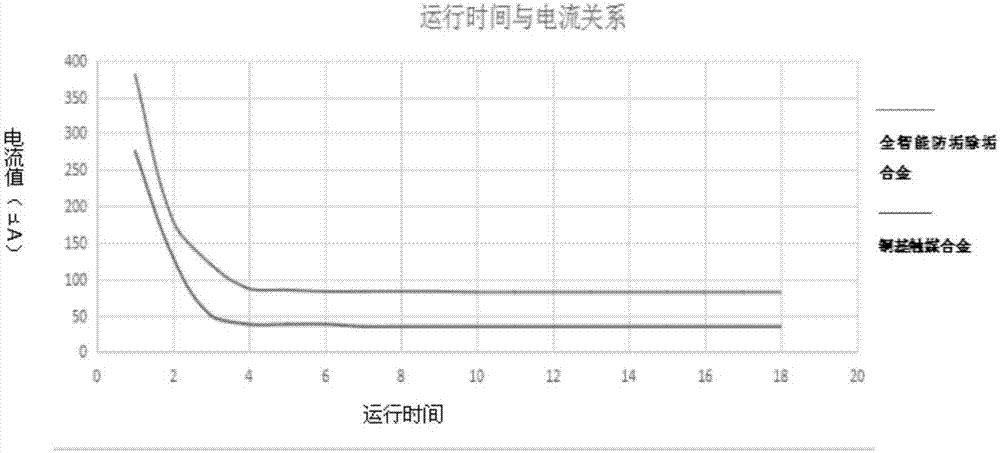

Image

Examples

Embodiment 1

[0017]The full intelligent anti-scaling and descaling alloy of the present invention, the mass percent of each component is: Cu: 55%, Ni: 15%, Zn: 10%, Sn: 8%, Ag: 4%, Fe: 3%, Nb: 2%, Mn: 2.5%, V: 0.45%, C: 0.05%, each component is synthesized into a columnar crystal alloy oriented along the S110 crystal axis.

[0018] The preparation method of the all-intelligent anti-scaling and descaling alloy is as follows: prepare raw materials according to the mass percentage of each component mentioned above, and the raw materials are lumps with a purity of more than 99.9%, and their volume is less than or equal to 2cm 3 ; Spread 3cm thick charcoal in the crucible of the heating furnace, evenly spread half of the Cu material on the charcoal by weight, then evenly spread all the Ni blocks on the Cu material, and then spread 3cm thick charcoal, and start the furnace Raise the temperature to 1380°C. After all the metals are melted, add all the Fe, V, Nb, and C blocks, stir until the metals...

Embodiment 2

[0020] The difference from the previous examples is that the mass percentages of the components in this example are: Cu: 45%, Ni: 18%, Zn: 15%, Sn: 10%, Ag: 4%, Fe: 2.5%, Nb: 3.5%, Mn: 1.5%, V: 0.48%, C: 0.02%, each component is compounded into a columnar crystal alloy which grows oriented along the S110 crystal axis.

[0021] The preparation method of this example is consistent with that described in Example 1.

Embodiment 3

[0023] The difference from the previous examples is that the mass percentages of the components in this example are: Cu: 57%, Ni: 13%, Zn: 8%, Sn: 7%, Ag: 6%, Fe: 5%, Nb: 1%, Mn: 2.5%, V: 0.45%, C: 0.05%, each component is synthesized into a columnar crystal alloy oriented along the S110 crystal axis.

[0024] The preparation method of this example is consistent with that described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com