High-fluidity polypropylene for production of folding stools and preparation method of high-fluidity polypropylene

A high-fluidity, polypropylene technology, applied in the field of polypropylene modification and preparation, can solve the problems of poor melt fluidity of polypropylene and restrictions on the development of polypropylene industry, so as to improve fluidity, improve cohesiveness, and improve processing efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

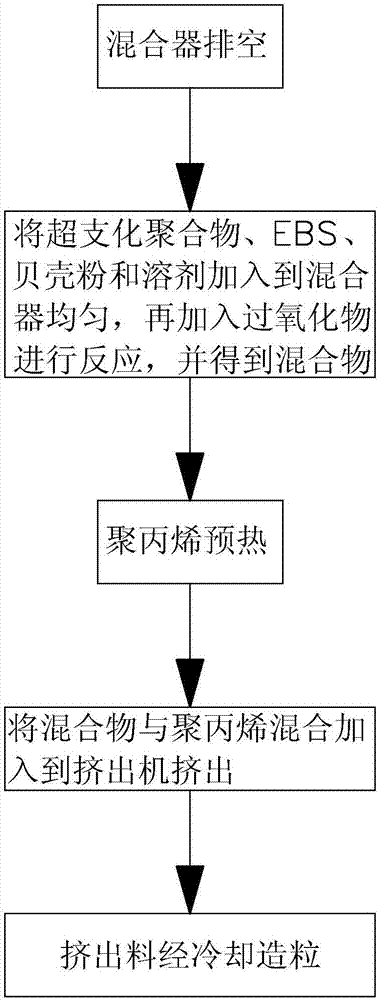

[0038] A kind of preparation method that is used to produce the high fluidity polypropylene of folding stool: S1, pass into nitrogen in mixer, mixer is evacuated, and hyperbranched polymer 14Kg, EBS12Kg, shell powder 10Kg and solvent 20Kg are added to Mix in a mixer, the stirring paddle in the mixer stirs the mixture at a speed of 500-800rpm, then add 2Kg of peroxide, and raise the temperature of the mixer to 120-160°C for 0.5-1h;

[0039] S2. Preheating 60Kg of polypropylene, the preheating temperature is 100-120°C, and the pressure is 0.05-0.08 MPa;

[0040] S3, adding the mixture in S1 and the preheated polypropylene in S2 to a screw extruder for extrusion;

[0041] After the extruded materials in S4 and S3 are cooled by cooling water, they are transported to the granulator for granulation.

[0042] Wherein, the hyperbranched polymer is a mixture of hyperbranched polyhydroxypolyurethane amide and hyperbranched polyhydroxypolyurethane with a weight ratio of 1:1.2.

[0043]...

Embodiment 2

[0047] The polypropylene preparation method of embodiment two to embodiment five and comparative example one and comparative example two is identical with the preparation method of embodiment one, and the weight of each component of embodiment two and embodiment five is shown in the table below:

[0048] components

[0049] Wherein, the hyperbranched polymer in Example 2 is a mixture of hyperbranched polycaprolactam and hyperbranched polyenantholactam, and its weight ratio is 1:1.5.

Embodiment 3

[0050] The hyperbranched polymer in embodiment three is hyperbranched polycaprolactam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com