Sintered refractory brick and making method thereof

A technology of refractory bricks and quartz powder is applied in the field of refractory materials, which can solve the problems affecting the service life and application fields of refractory bricks, high thermal conductivity of refractory bricks, insufficient thermal shock resistance, etc., and achieves significant thermal insulation effect and reduces thermal conductivity. , The effect of improving compressive strength and thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

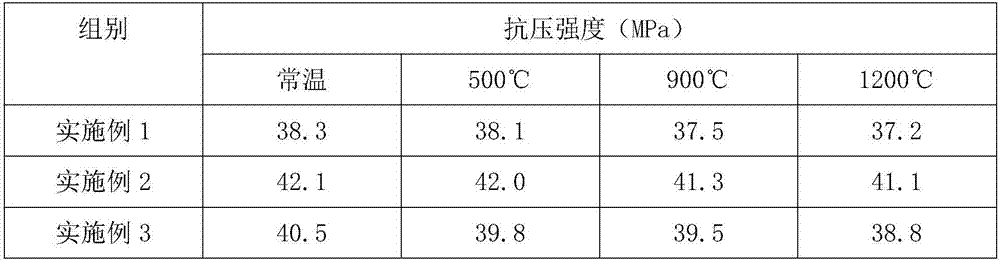

Embodiment 1

[0024] A kind of sintered refractory brick, the following raw materials are prepared to be prepared: 30kg of modified quartz powder, 25kg of magnesite slag, 15kg of dolomite powder, 15kg of bauxite, 10kg of diopside powder, 5kg of milk of lime, 6kg of expanded graphite, 3kg of niobium carbide powder, Boron nitride powder 3kg, silicon phosphide powder 3kg, silicon carbide fiber 4kg, activator 1kg, water reducing agent 1kg, foaming agent 1kg and foam stabilizer 1kg;

[0025] The modified quartz powder is prepared by the following steps: Weigh 30kg of quartz sand, soak it in a mixed solution of sodium carbonate and potassium permanganate for 2 hours, take it out and dry it, and add silane coupling agent KH550 equivalent to 2% of the weight of the quartz sand 1. The polyphenylene sulfone resin equivalent to 3% of the turbidite weight and the alumina equivalent to 1% of the quartz powder weight are stirred at 300r / min for 15min and ground after 70 mesh sieves to obtain the required ...

Embodiment 2

[0034] A kind of sintered refractory brick, the following raw materials are prepared to be prepared: 35kg of modified quartz powder, 30kg of magnesite slag, 20kg of dolomite powder, 20kg of bauxite, 15kg of diopside powder, 10kg of milk of lime, 9kg of expanded graphite, 5kg of niobium carbide powder, Boron nitride powder 5kg, silicon phosphide powder 5kg, silicon carbide fiber 6kg, activator 3kg, water reducing agent 2kg, foaming agent 3kg and foam stabilizer 3kg;

[0035] The modified quartz powder is prepared through the following steps: Weigh 35kg of quartz sand, put it into a mixed solution of sodium carbonate and potassium permanganate and soak it for 2.5 hours, take it out and dry it, and add a silane coupling agent equivalent to 3% of the weight of the quartz sand KH550, the polyphenylene sulfone resin equivalent to 4% of turbidite weight and the alumina equivalent to 2% of quartz powder weight are ground at 400r / min after stirring for 20min, and the required raw materi...

Embodiment 3

[0044]A kind of sintered refractory brick, the following raw materials are prepared to be prepared: 40kg of modified quartz powder, 35kg of magnesite slag, 25kg of dolomite powder, 25kg of bauxite, 20kg of diopside powder, 15kg of milk of lime, 12kg of expanded graphite, 7kg of niobium carbide powder, Boron nitride powder 7kg, silicon phosphide powder 7kg, silicon carbide fiber 8kg, activator 5kg, water reducing agent 3kg, foaming agent 5kg and foam stabilizer 5kg;

[0045] The modified quartz powder is prepared through the following steps: Weigh 40kg of quartz sand, soak it in a mixed solution of sodium carbonate and potassium permanganate for 3 hours, take it out and dry it, and add silane coupling agent KH550 equivalent to 4% of the weight of the quartz sand , the polyphenylene sulfone resin that is equivalent to 5% of turbidite weight and the aluminum oxide that is equivalent to 3% of quartz powder weight are ground after stirring 25min under 500r / min, cross 90 mesh sieves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com