ATP/g-C3N4-Ag composite material with high visible-light activity, and preparation method and application thereof

A composite material, g-c3n4-ag technology, applied in chemical instruments and methods, light water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as the degradation efficiency needs to be improved, and achieve excellent photoelectric catalytic performance. , Easy to obtain raw materials, good coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

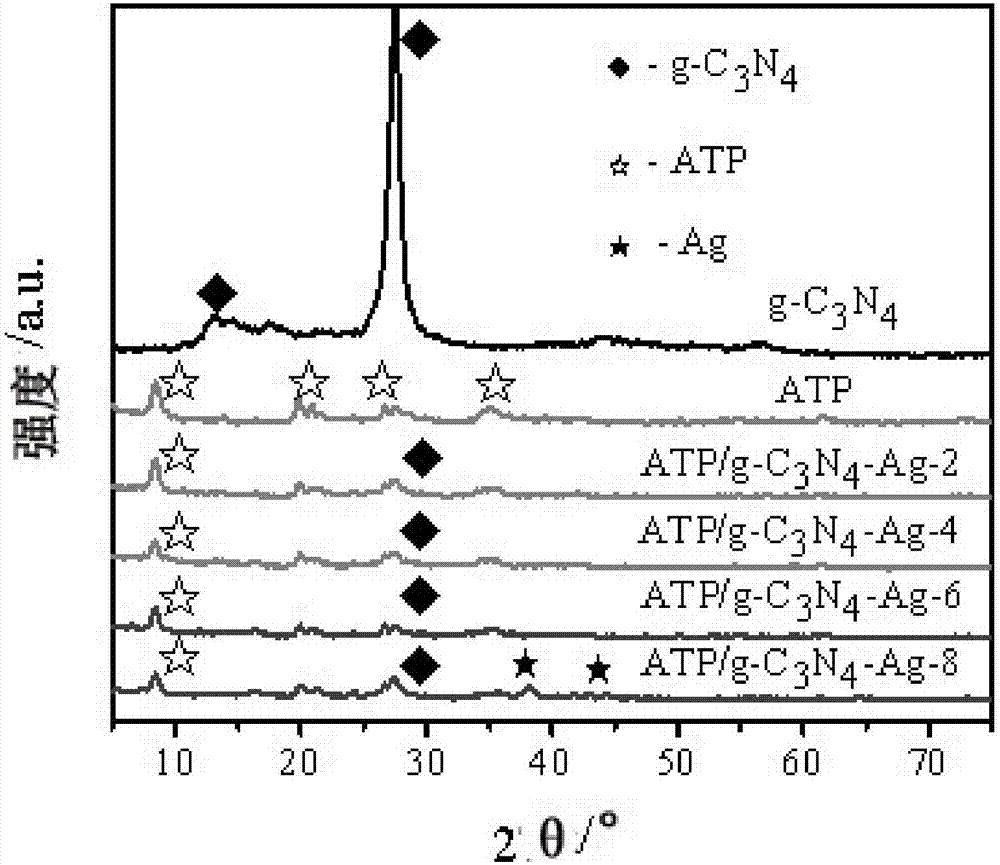

[0038] Another aspect of the present invention provides a preparation method for this material. The first step is the modification of attapulgite: mix attapulgite with an organic solvent, then add a silane coupling agent for modification, and the product is washed and dried Finally, the modified attapulgite is obtained; the second step is to load g-C 3 N 4 Preparation of the attapulgite: Disperse the modified attapulgite in deionized water, then add melamine for reflux reaction, freeze-dry the reaction solution and grind it, and then calcinate the ground product to obtain the loaded g-C 3 N 4 of attapulgite; step 3, loading of Ag: will load g-C 3 N 4 The attapulgite was dispersed in deionized water, and AgNO was added dropwise 3 solution, and NaBH was added dropwise 4 The solution was reacted and the product was filtered off and dried to obtain ATP / g-C 3 N 4 -Ag composite material.

[0039] In the first step described, the organic solvent is toluene; the silane couplin...

Embodiment 1

[0046] Embodiment 1: ATP / g-C is synthesized according to the following steps 3 N 4 -Ag-2 composite material:

[0047] (a) Weigh 12.0g of attapulgite and 140mL of toluene into the four-neck flask in turn, stir at 60°C for 0.5 h, add 10mL of KH560, and react at constant temperature for 4 h under stirring, then wash with toluene and absolute ethanol in sequence, And dry at 60°C to obtain ATP-KH560. (b) Weigh 0.400g of ATP-KH560 and ultrasonically disperse in deionized water for 1 hour to obtain solution A. Heat and dissolve 0.800g melamine in deionized water, mix it with solution A and condense and reflux at 80°C for 4h; freeze-dry the mixed solution after cooling to room temperature for 24h, grind and roast at 520°C in an air atmosphere to obtain ATP / g-C 3 N 4 Thin layer material. (c) Weigh 0.400g ATP / g-C 3 N 4 Thin layer material was dispersed in deionized water, after ultrasonic dispersion for 1h, 0.643mL 0.01g / mL AgNO was added dropwise 3 solution, after stirring for ...

Embodiment 2

[0048] Embodiment 2: ATP / g-C is synthesized according to the following steps 3 N 4 -Ag-4 composite material:

[0049] (a) Weigh 6.0g of attapulgite and 70mL of toluene into the four-neck flask in turn, stir at 60°C for 0.5 h, add 5mL of KH560, and react at constant temperature for 4 h under stirring, then wash with toluene and absolute ethanol in turn, And dry at 60°C to obtain ATP-KH560. (b) Weigh 0.800g of ATP-KH560 and ultrasonically disperse in deionized water for 1 hour to obtain solution A. Heat and dissolve 1.600g of melamine in deionized water, mix it with solution A and condense and reflux at 80°C for 4h; freeze-dry the mixed solution for 24h after cooling to room temperature, grind and roast at 520°C in an air atmosphere to obtain ATP / g-C 3 N 4 Thin layer material. (c) Weigh 0.800gATP / g-C 3 N 4 After ultrasonic dispersion in deionized water for 1 h, 2.625 mL of 0.02 g / mL AgNO was added dropwise 3 solution, after stirring for 1h, add 3.333 mL 0.06g / mL NaBH dro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com