Photoelectric composite cable for high-definition multimedia transmission and manufacturing method thereof

A photoelectric composite cable, high-definition multimedia technology, applied in the direction of communication cables, cables, light guides, etc., can solve the problems of small transmission capacity, difficult separation of optical units and electrical units, slow speed, etc., to improve signal transmission rate and excellent bending resistance The effect of large performance and transmission capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

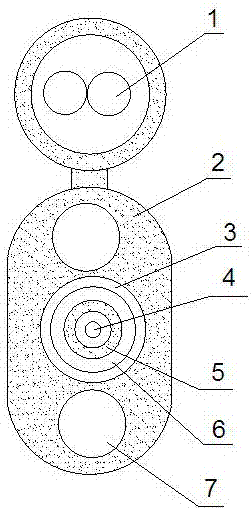

[0039] Take the 1-core tight-buffered optical fiber unit and the 2-core twisted-pair electrical unit as an example, which is designed as a flat structure, such as figure 1 As shown, a photoelectric composite cable for high-definition multimedia transmission, including an electrical unit 1, an optical unit, a reinforcing member 7 and an outer sheath 2, the upper and lower sides of the optical unit are provided with a reinforcing member 7, and the upper and lower sides of the optical unit are provided with an electrical unit 1. The outer sheath 2 wraps around the electrical unit 1, the reinforcing member 7 and the optical unit and forms an oval flat structure at the reinforcing member 7 and the optical unit. The electrical unit is an insulated electronic wire or a twisted pair, and the optical unit includes a central The tight-buffered optical fiber 4 is coated with a strengthening layer 5 outside the tight-bubbling optical fiber 4 , and the inner sheath 6 is extruded outside the...

Embodiment 2

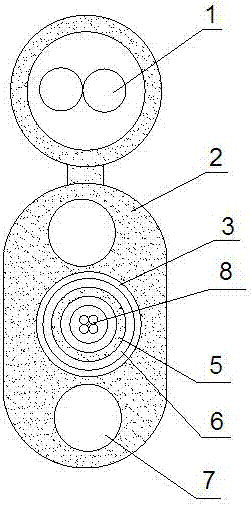

[0056] Taking the 4-core optical fiber microtube unit and 2-core twisted pair electric unit as an example, it is designed as a flat structure, such as figure 2 As shown, a photoelectric composite cable for high-definition multimedia transmission, including an electrical unit 1, an optical unit, a reinforcing member 7 and an outer sheath 2, the upper and lower sides of the optical unit are provided with a reinforcing member 7, and the upper and lower sides of the optical unit are provided with an electrical unit 1. The outer sheath 2 wraps around the electrical unit 1, the reinforcing member 7 and the optical unit and forms an oval flat structure at the reinforcing member 7 and the optical unit. The electrical unit is an insulated electronic wire or a twisted pair, and the optical unit includes a central The optical fiber microtube 8 is coated with a reinforcement layer 5 outside, the reinforcement layer 5 is extruded with an inner sheath 6, and the inner sheath 6 is longitudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com