Carbon-base coating high in hardness, resistant to abrasion and resistant to corrosion in emulsion environment on substrate surface and preparation method of carbon-base coating

An emulsion, high hardness technology, applied in the direction of coating, metal material coating process, superimposed layer plating, etc., can solve the problems of low service life and shortened service life, achieve effective protection and improve corrosion resistance , The effect of improving the binding force of the membrane base

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings. It should be noted that the following embodiments and terms are intended to facilitate the understanding of the present invention, but do not have any limiting effect on it.

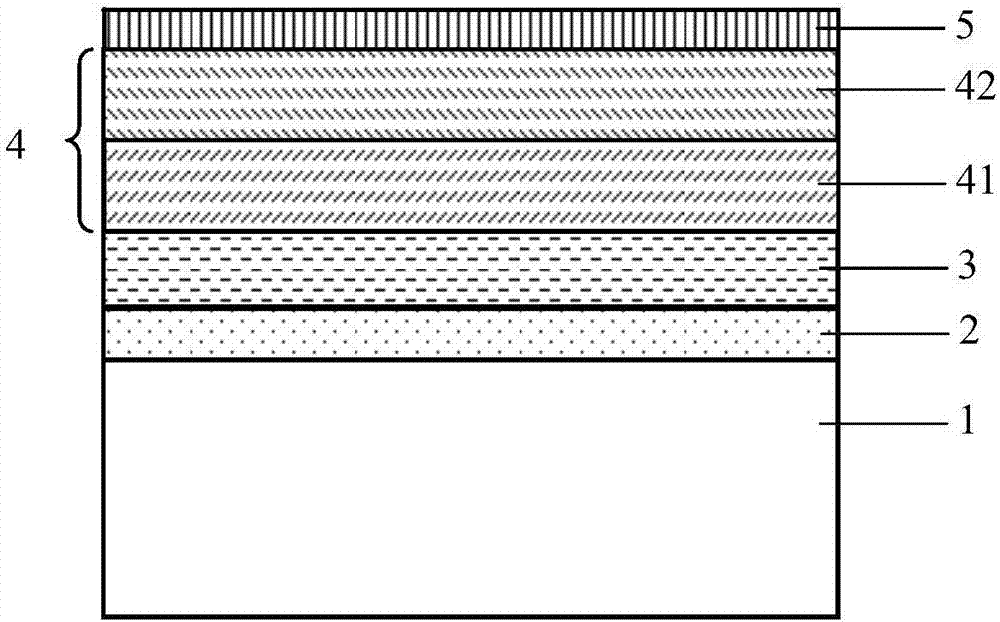

[0022] In this embodiment, the substrate is a hydraulic motor component, and the surface of the substrate is a carbon-based coating, such as figure 1 As shown, the surface of the self-substrate is the base layer 2, the surface of the base layer 2 is the transition layer 3, the surface of the transition layer 3 is the first functional layer 41, the surface of the first functional layer 41 is the second functional layer 42, and the surface of the second functional layer 42 is lubricated Layer 6.

[0023] The base layer 2 is a Cr layer.

[0024] The transition layer 3 is composed of metal Cr and WC, and along the upward direction of the substrate surface, the content of met...

PUM

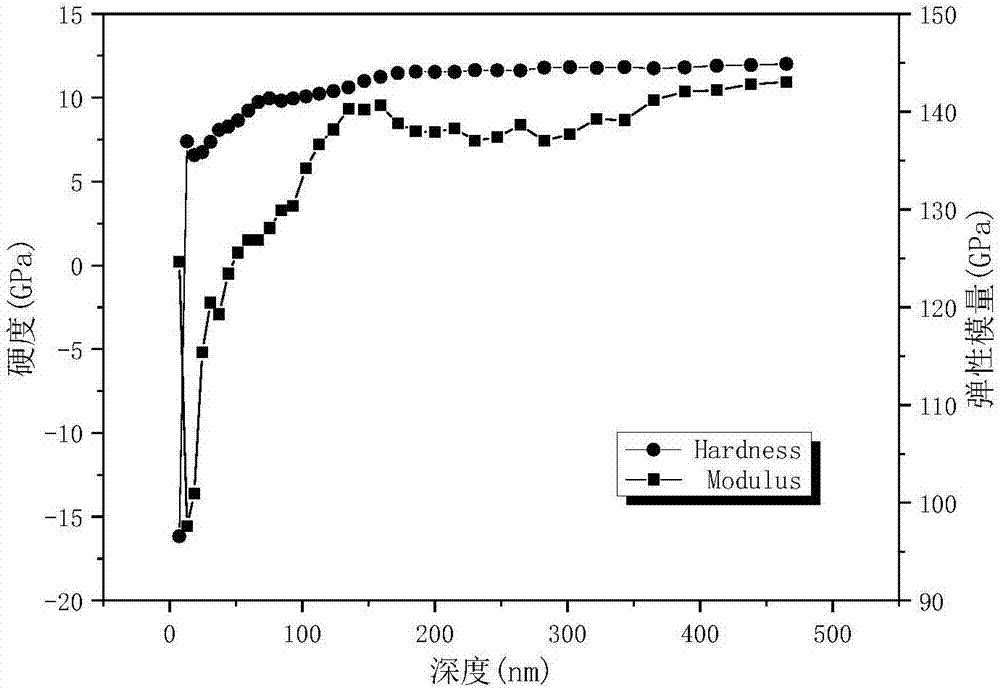

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com