Beneficiation method for high-carbon micro-fine particle sub-microscopic gold ore

A beneficiation method and fine-grained technology, which is applied in the beneficiation field of high-carbon fine-grained microscopic gold ore, can solve the problems of inability to realize effective recovery of gold, large amount of sodium cyanide, and low leaching rate, and achieve wide application range, The effect of low production cost and improving gold leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

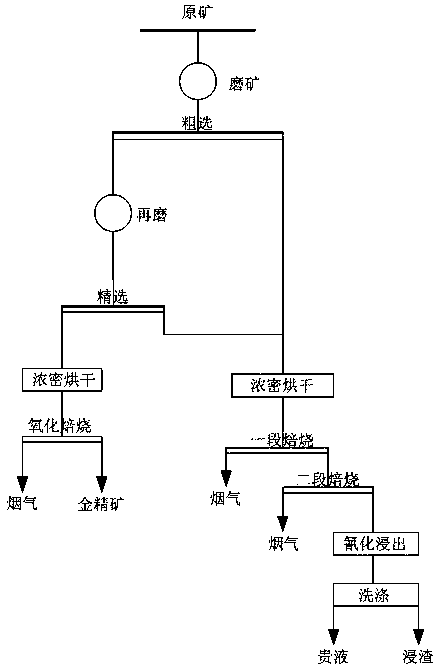

Image

Examples

Embodiment 1

[0015] 1. Grinding process: A carbon-containing fine-grained microscopic gold mine in Gansu, the gold grade is 4.41g / t, the grinding concentration is 55%, and the pH regulator sodium carbonate 3000g / t is added during grinding, and the gangue inhibitor Carboxymethyl cellulose: Sodium hexametaphosphate is added at a ratio of 1:1, 500g / t is added, and the amount of kerosene is 30g / t for grinding. The grinding fineness is less than 0.074mm, and the content is 80%.

[0016] 2. Flotation process: the mass percentage concentration of the pulp is 30%, the activator is copper sulfate, the dosage is 200 g / t, the foaming agent butyl xanthate is 200g / t, and the dosage of 2# oil is 30g / t, after roughing and sweeping, flotation coarse concentrate and flotation tailings are obtained.

[0017] 3. The coarse concentrate is regrinded and re-selected, the grinding concentration is 55%, and the gangue inhibitor carboxymethyl cellulose: sodium hexametaphosphate is added at a ratio of 1:1, and the ...

Embodiment 2

[0022] 1. Grinding process: A carbon-containing fine-grain microscopic gold mine in Tibet, the gold grade is 5.25g / t, the grinding concentration is 55%, and the pH regulator sodium carbonate 3500g / t and gangue inhibitor are added during grinding. Carboxymethyl cellulose: Sodium hexametaphosphate is added at a ratio of 1:1, 800g / t is added, and the amount of kerosene is 40g / t for grinding. The grinding fineness is less than 0.074mm, and the content is 85%.

[0023] 2. Flotation process: the mass percentage concentration of the pulp is 30%, the activator is copper sulfate, the dosage is 200 g / t, the foaming agent butylxanthate dosage is 250g / t, and the dosage of 2# oil is 30g / t, after roughing and sweeping, flotation coarse concentrate and flotation tailings are obtained.

[0024] 3. The coarse concentrate is regrinded and re-selected, the grinding concentration is 55%, and the gangue inhibitor carboxymethyl cellulose: sodium hexametaphosphate is added at a ratio of 1:1, and the...

Embodiment 3

[0029] 1. Grinding process: A carbon-containing fine-grain microscopic gold mine in Xinjiang, the gold grade is 3.26g / t, the grinding concentration is 55%, and the pH regulator sodium carbonate 3000g / t and gangue inhibitor are added during grinding. Carboxymethyl cellulose: Sodium hexametaphosphate is added at a ratio of 1:1, 600g / t is added, and the amount of kerosene is 35g / t for grinding. The grinding fineness is less than 0.074mm, and the content is 85%.

[0030] 2. Flotation process: the mass percentage concentration of the pulp is 30%, the activator is copper sulfate, the dosage is 250 g / t, the foaming agent butylxanthate dosage is 200g / t, and the dosage of 2# oil is 30g / t, after roughing and sweeping, flotation coarse concentrate and flotation tailings are obtained.

[0031] 3. Grinding the coarse concentrate, the grinding concentration is 55%, adding gangue inhibitor carboxymethyl cellulose: sodium hexametaphosphate at 1:1, adding 300g / t grinding fineness to less than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com