Production method and applications of high-quality xanthan gum

A production method and technology for xanthan gum, applied in the field of microbial fermentation, can solve the problems of low quality and low production yield of xanthan gum, and achieve the effects of high viscosity, shortened growth period, and reduced content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. The specific steps of Xanthomonas axonopodis fermentation to produce xanthan gum are as follows:

[0033] (1) Strain activation: inoculate Xanthomonas rugosa strain FJAT-10151 on TSB medium, and culture at 28° C. for 24 hours. Among them, Xanthomonas rugosa FJAT-10151 is preserved in the General Microorganism Center of China Committee for the Collection of Microorganisms, and the preservation number is CGMCC No.10271. TSB medium was purchased from BD Company, USA.

[0034] (2) Expanded cultivation of seeds: Pick a single colony and inoculate it into the seed medium, culture at 170 r / min at 30°C for 16 hours, and expand the cultivation. The formula of the seed medium is 20g L of sucrose -1 , peptone 5g·L -1 , yeast extract powder 5g·L -1 , pH 7.0.

[0035] (3) Shake flask fermentation: the liquid volume of the fermentation medium is 25-125mL / 250mL, the inoculum size is 2-10%, 28°C, 170r / min shaker culture for 12-120h.

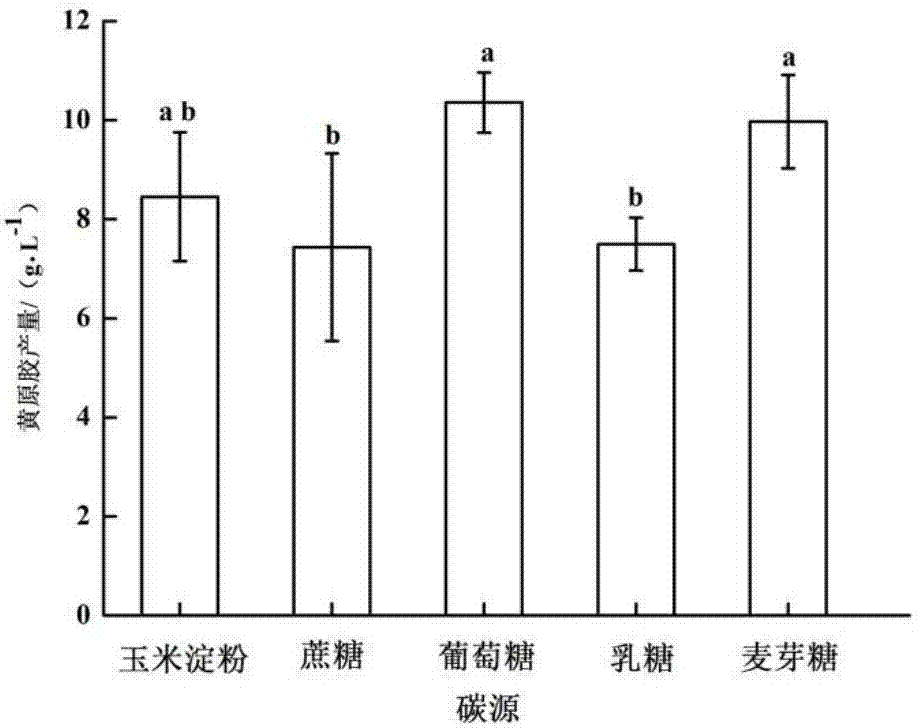

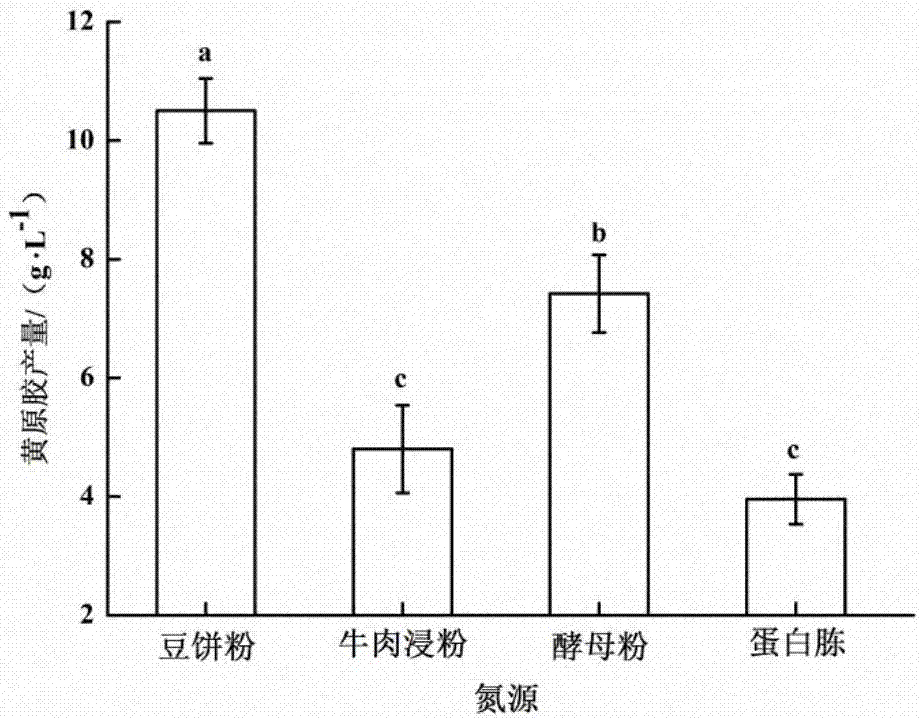

[0036] 30g·L fermentation medium was selec...

Embodiment 2

[0057] 1. The specific steps of producing xanthan gum by fermentation of Xanthomonas rugosa are as follows:

[0058] (1) Strain activation: inoculate Xanthomonas rugosa strain FJAT-10151 on TSB medium, and culture at 28° C. for 24 hours.

[0059] (2) Expanded cultivation of seeds: Pick a single colony and inoculate it into the seed medium, culture at 170 r / min at 30°C for 16 hours, and expand the cultivation. The formula of the seed medium is 20g L of sucrose -1 , peptone 5g·L -1 , yeast extract powder 5g·L -1 , pH 7.0.

[0060] (3) Shake flask fermentation: the liquid volume of the fermentation medium is 50mL / 250mL, the inoculum size is 8%, 28°C, 170r / min shaker culture for 72h.

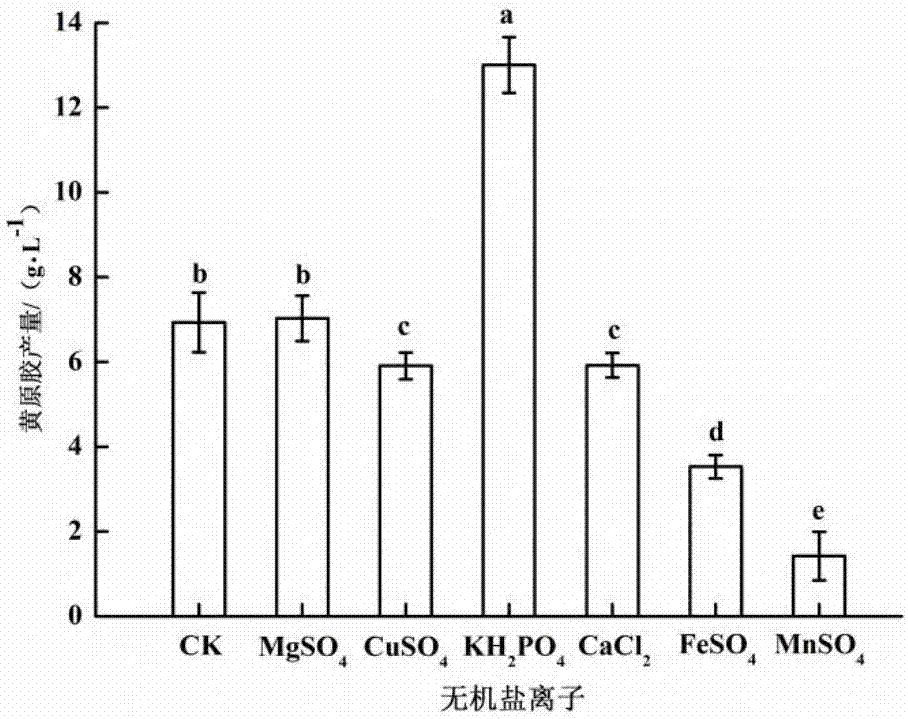

[0061] Optimize the formulation of the fermentation medium, and select three factors that have a relatively large impact: glucose, bean cake powder, and KH 2 PO 4 For the fermentation factor, select three levels for each factor, press L 9 (3 3 ) Orthogonal table design fermentation experimen...

Embodiment 3

[0088] 1. Application of xanthan gum in ice cream production

[0089] (1) Strain activation: According to aseptic operation, a loop of Lactobacillus casei FJAT-7928 and Streptococcus thermophilus FJAT-7927 were respectively inserted into MRS medium (purchased from Beijing Land Bridge Technology Co., Ltd.), and cultured The volume of the base is 30mL / 150mL Erlenmeyer flask, and it is cultured statically in a water-proof incubator at 37°C for 48h.

[0090] (2) Expansion culture of strains: the fermented broth of Lactobacillus casei FJAT-7928 and Streptococcus thermophilus FJAT-7927 (volume ratio 1:1) was inserted into fresh milk, the inoculum amount was 3%, and placed at 37°C Static culture in a water-type constant temperature incubator for 24 hours, as a lactic acid bacteria starter.

[0091] (3) Fermentation of jujube: Take appropriate amount of jujube and mash, add 5% lactic acid bacteria starter, ferment at 37°C for 24 hours.

[0092] (4) Ice cream production: Add 5% ice c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com