A self-emulsifying non-ionic water-based epoxy curing agent

A water-based epoxy, non-ionic technology, applied in the direction of epoxy resin glue, epoxy resin coating, adhesive, etc., can solve the problems of difficult emulsification of epoxy resin, incomplete curing, slowing down the curing speed of curing agent, etc., to achieve system Better stability, high production efficiency, and improved compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

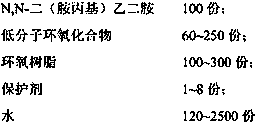

[0031] The self-emulsifying nonionic water-based epoxy curing agent of the present embodiment comprises the following components by weight:

[0032]

[0033] After the self-emulsifying non-ionic water-based epoxy curing agent of the present embodiment is mixed and stirred in proportion to epoxy resin, a stable white emulsion is formed; after the emulsion is diluted to 20% content, the coating film is surface-dried for 2 hours and hard-dried for 12 hours; the coating film has no The color is transparent, uniform and bright, the gloss is 70, the adhesion is grade 1, and the hardness is 3-4H.

Embodiment 2

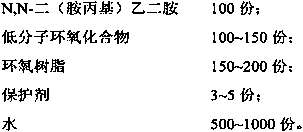

[0035] The self-emulsifying nonionic water-based epoxy curing agent of the present embodiment comprises the following components by weight:

[0036]

[0037] After the self-emulsifying non-ionic water-based epoxy curing agent of this embodiment is mixed and stirred in proportion to epoxy resin, a stable white emulsion is formed; the emulsion is diluted to a content of 20% and the coating film is surface-dried for 2.5 hours and hard-dried for 14 hours; Colorless and transparent, uniform and bright, gloss 65, adhesion level 1, hardness 3-4H.

Embodiment 3

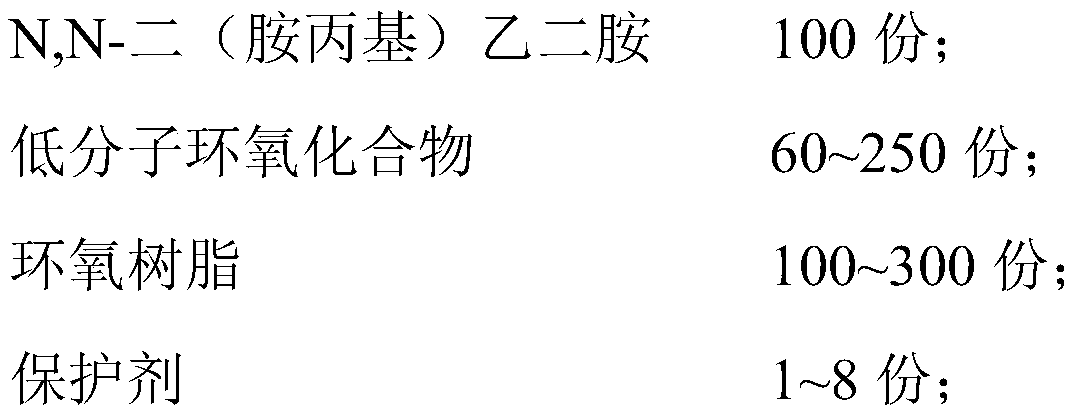

[0039] The self-emulsifying nonionic water-based epoxy curing agent of the present embodiment comprises the following components by weight:

[0040]

[0041] After the self-emulsifying non-ionic water-based epoxy curing agent of this embodiment is mixed and stirred in proportion to epoxy resin, a stable white emulsion is formed; the emulsion is diluted to a content of 20% and the coating film is surface-dried for 2.5 hours and hard-dried for 14 hours; Colorless and transparent, uniform and bright, gloss 60, adhesion level 2, hardness 2-3H.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| luster | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com