Manufacturing method for foot pedal

A manufacturing method and technology of foot pedals, applied in the field of foot pedal manufacturing, can solve the problems of less than ideal fatigue resistance of metal materials, environmental impact and human hazards, poor anti-slip properties of metal materials, etc., and achieve light weight , Guarantee fire safety and personal safety, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

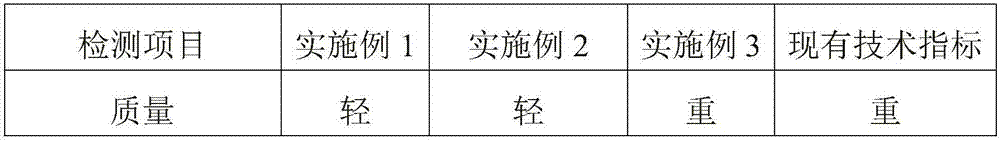

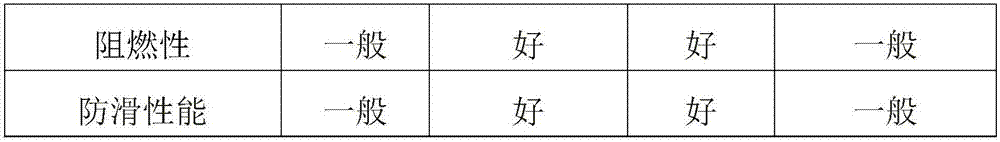

Examples

Embodiment 1

[0027] A method for manufacturing a pedal, comprising the steps of:

[0028] (1) Raw material melting

[0029] Put industrial pure aluminum, Al-rare earth master alloy, industrial magnesium ingot and aluminum-silicon master alloy into the melting furnace, and melt at 700°C for 10 minutes, stir the melt during melting to accelerate melting, and mix well;

[0030] (2) Pouring

[0031] The metal mold is preheated to 200°C and painted with paint, and then preheated to 200°C for pouring. The raw materials are poured into the mold. The pouring time is 30-50s, and the pouring temperature is 720°C. After pouring, take it out and cast it after 2 minutes. Check the surface condition of the grooved pedal. The composition ratio of the paint is: talcum powder: 100g, water glass: 50g, water: 500ml;

[0032] (3) Quenching

[0033] Forced air cooling is adopted, and four centrifugal fans are installed on the top and bottom of the main body of the pedal, so that the temperature of the main ...

Embodiment 2

[0041] A method for manufacturing a pedal, comprising the steps of:

[0042] (1) Raw material melting

[0043] Put industrial pure aluminum, Al-rare earth master alloy, industrial magnesium ingot and aluminum-silicon master alloy into the melting furnace, and melt at 710°C for 13 minutes, stir the melt during melting to accelerate melting, and mix well;

[0044] (2) Pouring

[0045] The metal mold is preheated to 250°C and painted with paint, and then preheated to 250°C for pouring. The raw materials are poured into the mold, the pouring time is 40s, the pouring temperature is 725°C, and the cast tank is taken out after 2.5 minutes after pouring Type pedal, check its surface condition, the composition ratio of paint is: talcum powder: 100g, water glass: 50g, water: 500ml;

[0046] (3) Quenching

[0047] Forced air cooling is adopted, and four centrifugal fans are installed on the upper and lower sides of the main body of the pedal, so that the temperature of the main body o...

Embodiment 3

[0055] A method for manufacturing a pedal, comprising the steps of:

[0056] (1) Raw material melting

[0057] Put industrial pure aluminum, Al-rare earth master alloy, industrial magnesium ingot and aluminum-silicon master alloy into the melting furnace, and melt at 720°C for 16 minutes, stir the melt during melting to accelerate melting, and mix well;

[0058] (2) Pouring

[0059]The metal mold is preheated to 300°C and painted with paint, and then preheated to 300°C for pouring. The raw materials are poured into the mold, the pouring time is 50s, and the pouring temperature is 730°C. After pouring, take out the cast groove after 3 minutes. Pedal, check its surface condition, the composition ratio of the paint is: talcum powder: 100g, water glass: 50g, water: 500ml;

[0060] (3) Quenching

[0061] Forced air cooling is adopted, and four centrifugal fans are installed on the upper and lower sides of the main body of the pedal, so that the temperature of the main body of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com