Cooling device for performing forced air cooling with sulfur dioxide gas

A technology of forced air cooling and cooling devices, applied in heat exchange equipment, damage protection, fixed tubular conduit components, etc., can solve problems affecting product quality, fast corrosion speed, short life, etc., to reduce corrosion phenomena and reduce impact degree, structure is simple and practical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

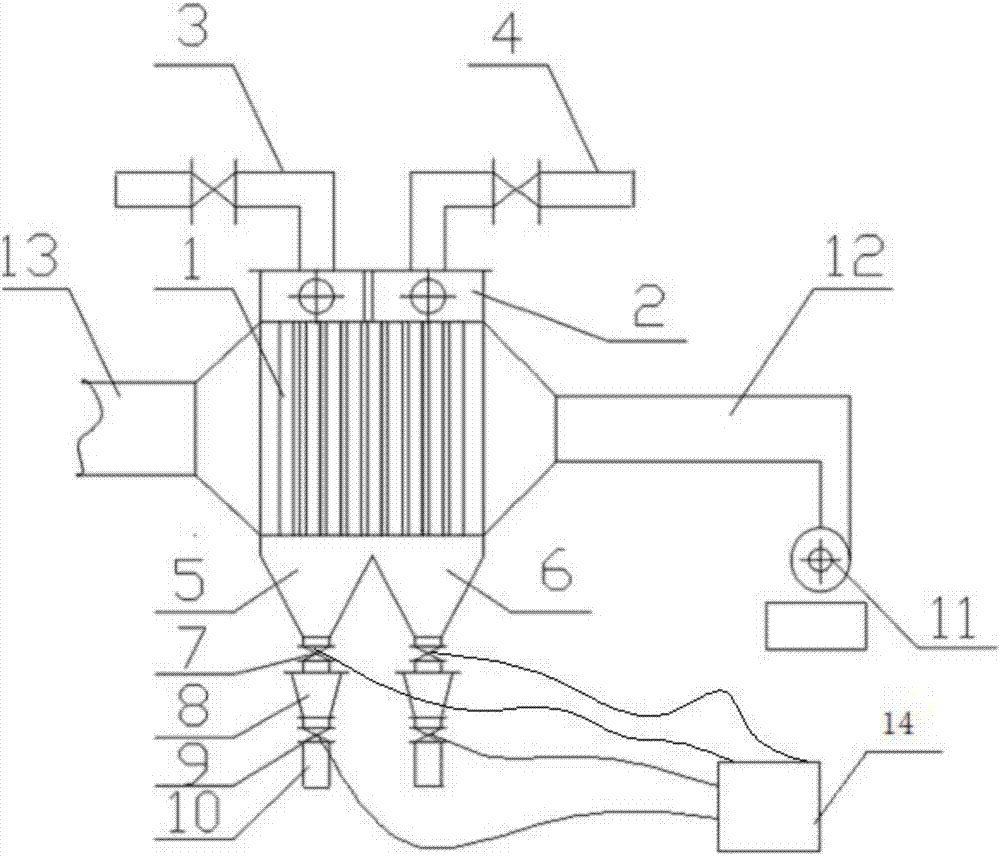

[0017] like figure 1 As shown, a sulfur gas forced air-cooled cooling device includes a cooler 1 and a blower 11. The top of the cooler 1 is provided with two sulfur gas chambers 2, wherein one of the sulfur gas chambers 2 is connected with an inlet pipe 3 for inputting the sulfur gas to be cooled, and the other said sulfur gas chamber 2 is connected with the The outlet pipe 4 for the output of the cooled sulfur gas after the cooler 1; To provide cold air for cooling the sulfur gas, the side of the blower 11 opposite to the air inlet pipe 12 is provided with a tail gas discharge pipe 13 for discharging the heat-exchanged cold air.

[0018] The bottom of the cooler 1 is connected with a primary ash chamber 5 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com