A construction method for an underground garage

A technology of underground garage and construction method, which is applied to buildings where cars are parked, artificial islands, water conservancy projects, etc. It can solve problems such as bending, limiting the use area of steel sheet piles, and low space requirements for environmental protection, so as to improve construction speed and improve The effect of improving construction efficiency and construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

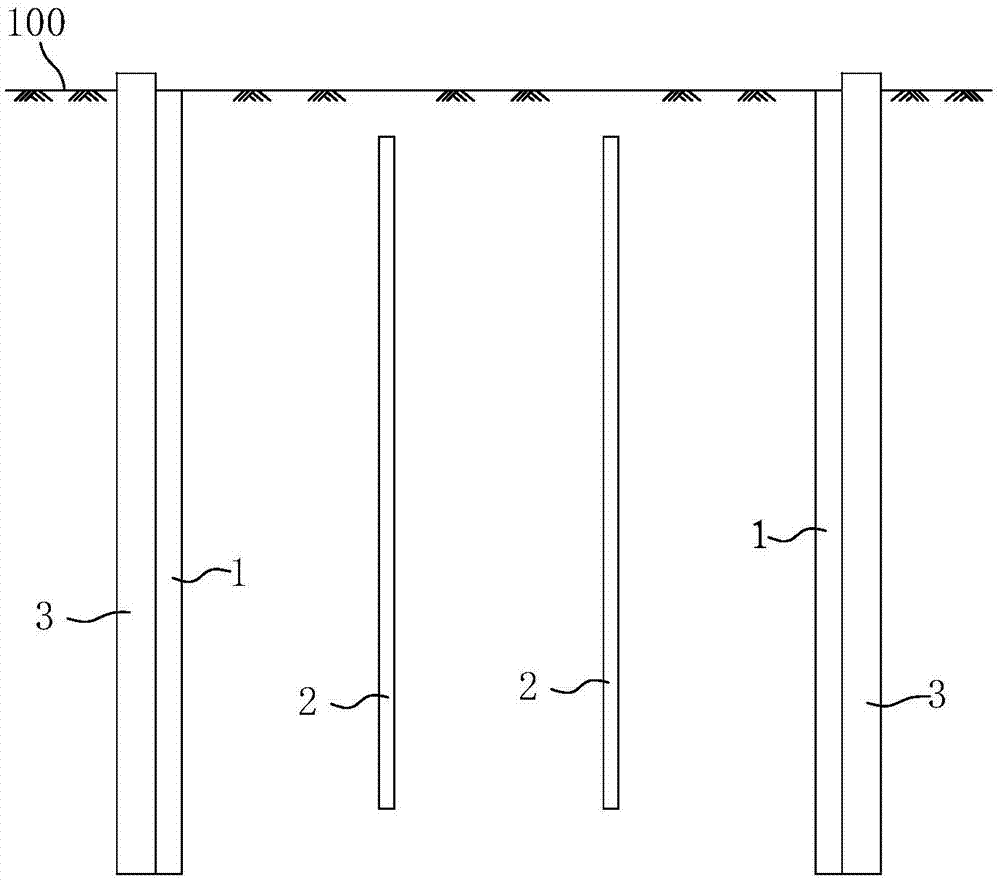

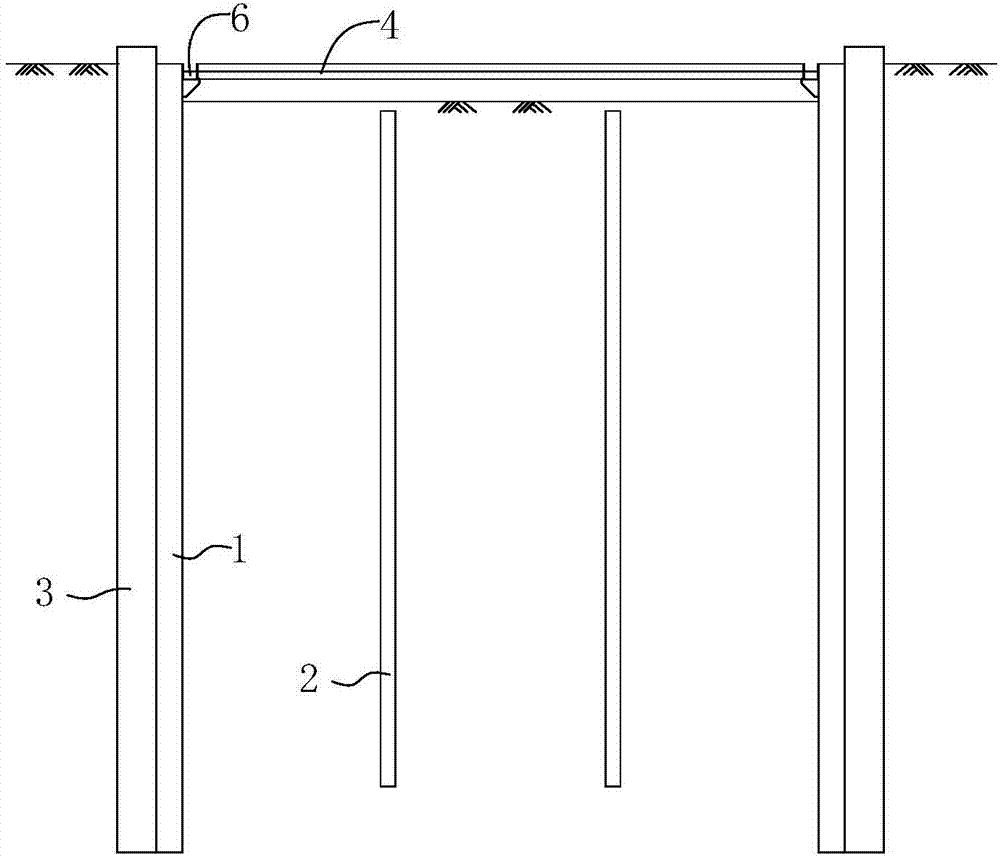

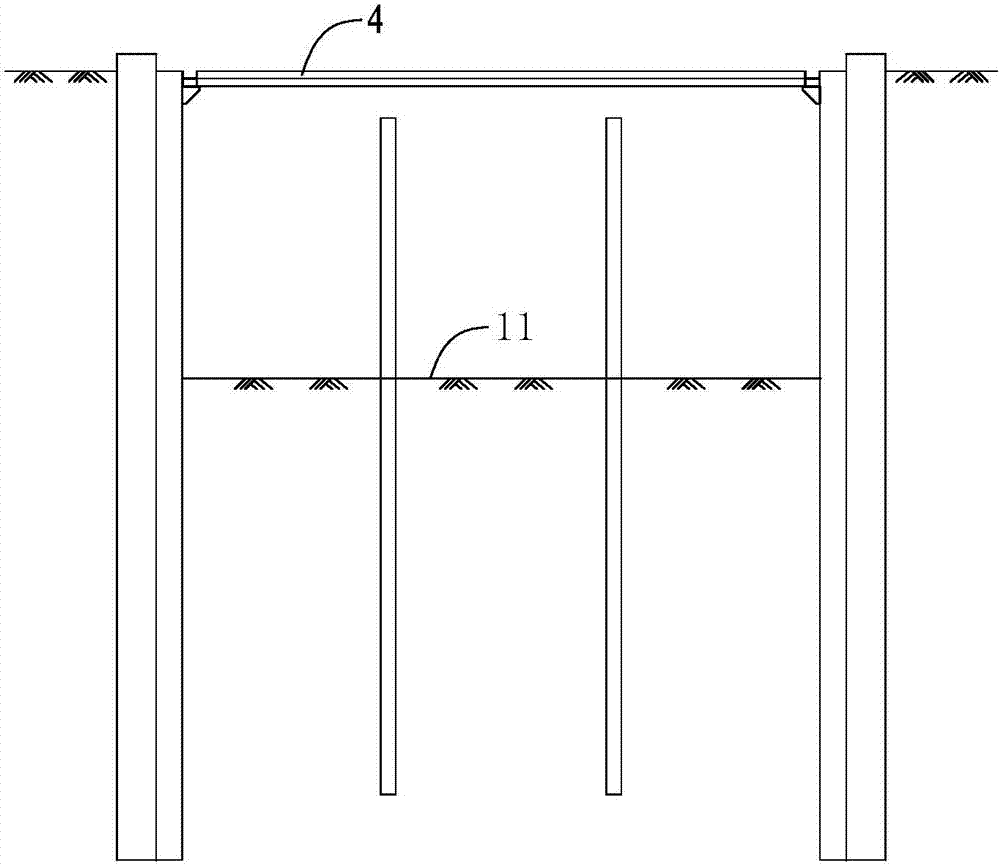

Method used

Image

Examples

Embodiment 2

[0077] In this embodiment, the underground garage to be built has four floors of parking platforms, including three floors of intermediate parking platforms and one floor of bottom parking platforms, which are divided into two upper and lower construction sections, wherein the first construction section above includes two The parking platform in the middle of the first floor, the second construction section below includes a middle parking platform on the first floor and a floor parking platform, except that the second construction section lacks a middle parking platform on the first floor, and the specific construction steps are similar to those in Example 1. Please refer to Embodiment 1 for construction steps.

Embodiment 3

[0079] In this embodiment, the constructed underground garage has eight floors of parking platforms, including seven floors of intermediate parking platforms and one floor of bottom parking platforms, which are divided into three construction sections from top to bottom, which are called the first floor from top to bottom. A construction section, a second construction section and a third construction section, wherein the construction of the first construction section includes a two-story intermediate parking platform, the second construction section includes a three-story intermediate parking platform, and the third construction section includes The middle parking platform and the bottom parking platform on the second floor.

[0080] During construction, follow the steps below:

[0081] (1B) This step is the same as the step (1A) in the embodiment 1, please refer to the step (1A) in the embodiment 1 for the specific construction, and will not repeat it here.

[0082] (2B) Con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com