A spray welding method for chemical pump flow parts

A technology for overcurrent components and chemical pumps, which is applied in melting spray plating, metal material coating process, coating, etc., can solve the problems of loss of spray welding, poor bonding strength, and high brittleness of cast iron, and achieve the improvement effect. , Improve the effect of wear resistance and not easy to shell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

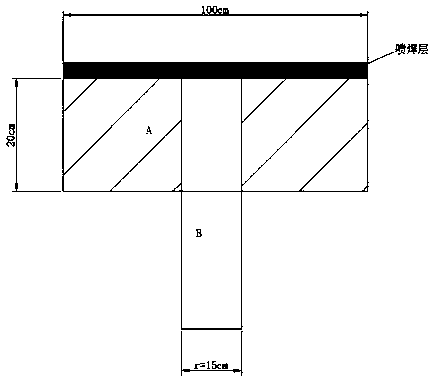

Image

Examples

Embodiment 1

[0016] A spray welding method for wetted parts of a chemical pump, comprising the following steps:

[0017] (1) Spray activation liquid on the flow-passing parts, wherein the activation liquid is made of the following components by weight: 8 parts of sodium ethylenediaminopropanesulfonate, 4 parts of 9-decenoic acid, 3,4,5-tri 12 parts of fluorobenzoic acid, 2 parts of potassium tripolyphosphate, 3 parts of citric acid, 180 parts of water;

[0018] (2) After 20 minutes, clean the activation solution on the flow-passing parts, then use a hot air blower to dry the flow-passing parts, and preheat the flow-passing parts to 160°C;

[0019] (3) Spray a layer of mixed alloy powder evenly on the surface of the preheated flow parts, and then carry out spray welding and remelting treatment on the flow parts. When remelting, the distance between the muzzle of the remelting gun and the surface of the workpiece is 30mm. The distance from the edge of the spray welding layer is 10mm. When t...

Embodiment 2

[0024] A spray welding method for wetted parts of a chemical pump, comprising the following steps:

[0025] (1) Spray activation solution on the flow-passing parts, wherein the activation solution is made of the following components by weight: 9 parts of sodium ethylenediaminopropanesulfonate, 5 parts of 9-decenoic acid, 3,4,5-tri 13 parts of fluorobenzoic acid, 3 parts of potassium tripolyphosphate, 4 parts of citric acid, 190 parts of water;

[0026] (2) After 25 minutes, clean the activation solution on the flow-passing parts, then use a hot air blower to dry the flow-passing parts, and preheat the flow-passing parts to 180°C;

[0027] (3) Spray a layer of mixed alloy powder evenly on the surface of the preheated flow parts, and then carry out spray welding and remelting treatment on the flow parts. When remelting, the distance between the muzzle of the remelting gun and the surface of the workpiece is 35mm. The distance from the edge of the spray welding layer is 13mm. Wh...

Embodiment 3

[0032] A spray welding method for wetted parts of a chemical pump, comprising the following steps:

[0033] (1) Spray activation solution on the flow-passing parts, wherein the activation solution is made of the following components by weight: 10 parts of sodium ethylenediaminopropanesulfonate, 6 parts of 9-decenoic acid, 3,4,5-tri 15 parts of fluorobenzoic acid, 4 parts of potassium tripolyphosphate, 5 parts of citric acid, 200 parts of water;

[0034] (2) After 30 minutes, clean the activation solution on the flow-passing parts, then use a hot air blower to dry the flow-passing parts, and preheat the flow-passing parts to 200°C;

[0035] (3) Spray a layer of mixed alloy powder evenly on the surface of the preheated flow parts, and then carry out spray welding and remelting treatment on the flow parts. When remelting, the distance between the muzzle of the remelting gun and the surface of the workpiece is 40mm. The distance from the edge of the spray welding layer is 15mm. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com