High-transparency and low-cost polylactic acid composite material and preparation method thereof

A composite material and polylactic acid technology, which are applied in the field of high-transparency and low-cost polylactic acid composite materials and their preparation, can solve the problem of restricting the application of polylactic acid/starch blend materials, the color yellowing of polylactic acid composite materials, and the application cost of polylactic acid. Advanced problems, to achieve the effect of being suitable for industrial production, reducing application cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1 A kind of polylactic acid composite material with high transparency and low cost

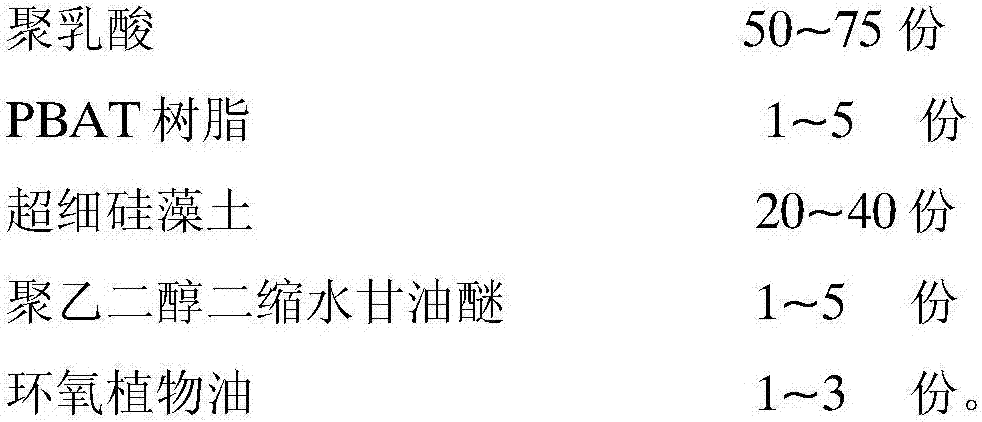

[0051] Contains components in parts by weight:

[0052]

[0053] The preparation process is as follows:

[0054] At 105°C, polylactic acid, PBAT resin and diatomaceous earth were mixed uniformly and dried for 30 minutes using a high-speed mixer, then polyethylene glycol (400) diglycidyl ether and epoxidized soybean oil were added and mixed for 5 minutes, and then Use twin-screw extruder to melt extrude, draw strands, air-cool, granulate, and seal the package. The screw length-to-diameter ratio of the twin-screw extruder is 36:1, and the melt blending temperature is 170°C to 180°C.

Embodiment 2

[0055] Embodiment 2 A kind of polylactic acid composite material with high transparency and low cost

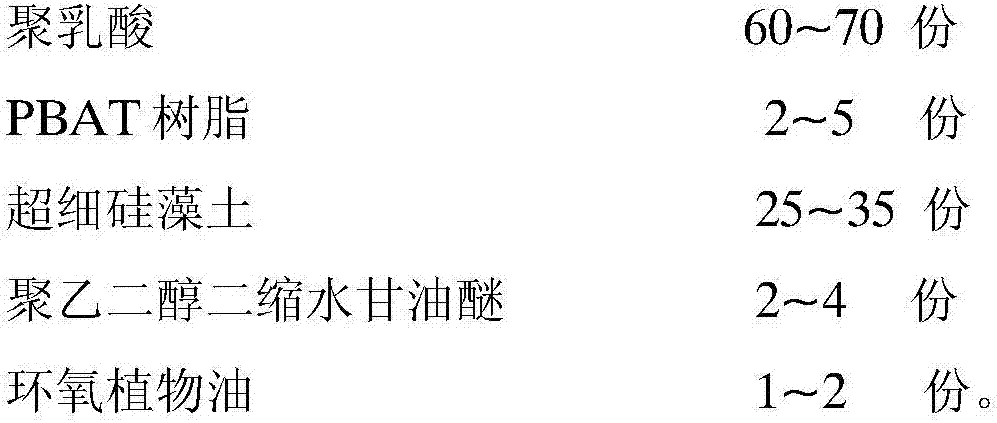

[0056] Contains components in parts by weight:

[0057]

[0058] The preparation process is as described in Example 1.

Embodiment 3

[0059] Embodiment 3 A kind of polylactic acid composite material with high transparency and low cost

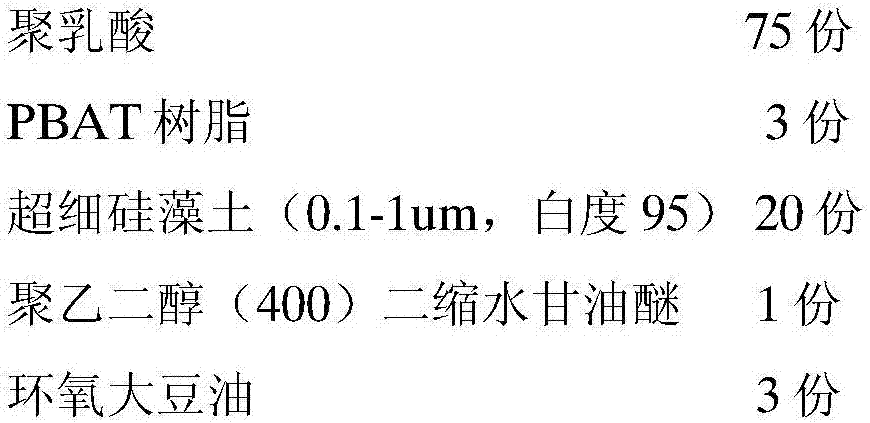

[0060] Contains components in parts by weight:

[0061] The formula is as follows:

[0062]

[0063] The preparation process is as described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com