Sun-proof and anti-corrosion cable sheath material and preparation method thereof

A cable sheath material and anti-corrosion technology, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve problems such as aging and cracking of cable sheaths, affecting life and work, and deterioration of transmission performance, reaching a broad market and application Foreground, small bulk density, excellent acid and alkali resistance and the effect of chemical agent corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

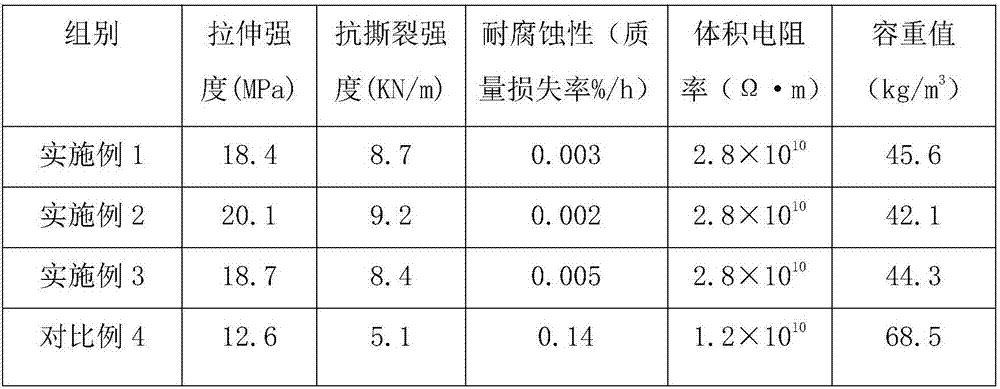

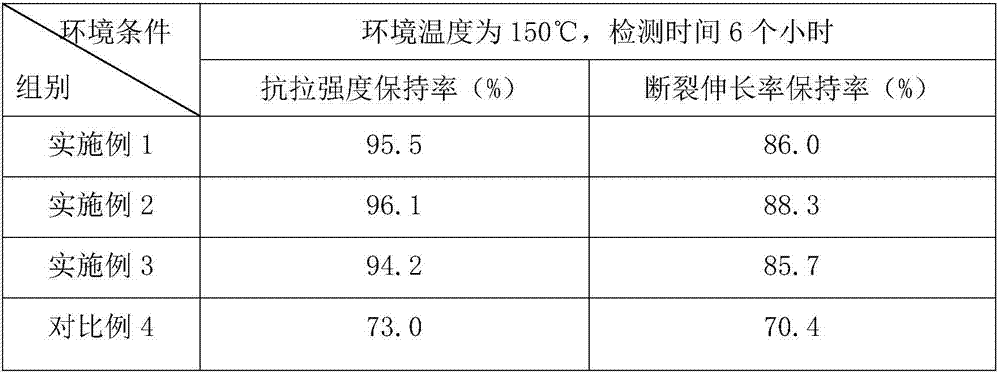

Examples

Embodiment 1

[0025] A sun-resistant and anti-corrosion cable sheath material, the following raw materials are weighed for use: chlorinated polyethylene 60kg, thermoplastic polyurethane elastomer 25kg, polyphenylene sulfone resin 20kg, modified sodium zeolite powder 15kg, sodium-based bentonite 5kg, Microcrystalline wax 4kg, glass fiber 6kg, boron nitride 3kg, dioctyl phthalate 5kg, diphenyl phosphate 4kg, adhesive 1kg, antistatic agent 1kg, antioxidant 1kg and anti-radiation agent 1kg;

[0026] The above-mentioned modified sodium zeolite powder is prepared by the following steps: take 15 kg of sodium zeolite and crush it through a 100-mesh sieve to obtain sodium zeolite powder, then place the sodium zeolite powder in a calcination furnace at 360 ° C for 1 hour, and then roast the calcined Sodium zeolite powder is conveyed in the high-speed kneader, add the aluminate coupling agent that is equivalent to 3% of fly ash weight, 2% sodium lignosulfonate, 2% triethyl citrate and 1% liquid paraffi...

Embodiment 2

[0033] A sun-resistant and anti-corrosion cable sheathing material, the following raw materials are weighed for use: 70kg of chlorinated polyethylene, 30kg of thermoplastic polyurethane elastomer, 25kg of polyphenylene sulfone resin, 20kg of modified sodium zeolite powder, 10kg of sodium bentonite, Microcrystalline wax 6kg, glass fiber 8kg, boron nitride 5kg, dioctyl phthalate 6kg, diphenyl phosphate 5kg, adhesive 3kg, antistatic agent 3kg, antioxidant 3kg and anti-radiation agent 3kg;

[0034] The above-mentioned modified sodium zeolite powder is prepared by the following steps: take 20 kg of sodium zeolite and crush it through a 150-mesh sieve to obtain sodium zeolite powder, then place the sodium zeolite powder in a calcination furnace at 370 ° C for 1.5 h, and then roast the The sodium zeolite powder is transported to the high-speed kneader, and the aluminate coupling agent equivalent to 4% of the weight of fly ash, 3% sodium lignosulfonate, 3% triethyl citrate and 2% liqui...

Embodiment 3

[0041] A sun-resistant and anti-corrosion cable sheath material, the following raw materials are weighed for use: 80kg of chlorinated polyethylene, 35kg of thermoplastic polyurethane elastomer, 30kg of polyphenylene sulfone resin, 25kg of modified sodium zeolite powder, 15kg of sodium bentonite, Microcrystalline wax 8kg, glass fiber 10kg, boron nitride 7kg, dioctyl phthalate 7kg, diphenyl phosphate 6kg, adhesive 5kg, antistatic agent 5kg, antioxidant 5kg and anti-radiation agent 5kg;

[0042] The above-mentioned modified sodium zeolite powder is prepared by the following steps: take 25 kg of sodium zeolite and crush it through a 200-mesh sieve to obtain sodium zeolite powder, then place the sodium zeolite powder in a calcination furnace at 380 ° C for 2 hours, and then roast the roasted Sodium zeolite powder is conveyed in the high-speed kneader, adds the aluminate coupling agent that is equivalent to 5% of fly ash weight, 4% sodium lignosulfonate, 4% triethyl citrate and 3% li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com