Hemisphere drawing method

A hemispherical and pre-drawing technology, which is applied in the field of aerospace, can solve the problems of high processing cost, low heating time and low processing efficiency of forming speed products, and achieve the effect of low production cost, easy control of processing technology, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A hemispherical drawing method is characterized in that: comprising the following steps:

[0046] a. Cutting and blanking, cutting and blanking the plate to make blank material;

[0047] b. Pre-drawing, using the pre-drawing die to carry out the initial drawing of the blank material in a high-temperature environment, and the drawing makes the blank material into a cylinder and a semi-finished product;

[0048] c. Turning edge, the edge of the semi-finished product has a flange edge, and the flange edge of the semi-finished product is removed through turning processing to make a semi-finished product for use;

[0049] d. Hot drawing, install the smooth semi-finished product on the hot drawing die and place it in a high temperature environment for the second drawing, and draw it into a hemisphere;

[0050] e. Turning, the deep-drawn hemisphere is subjected to turning processing to remove the flange edge produced by the second drawing.

[0051]Based on the above-mentione...

Embodiment 2

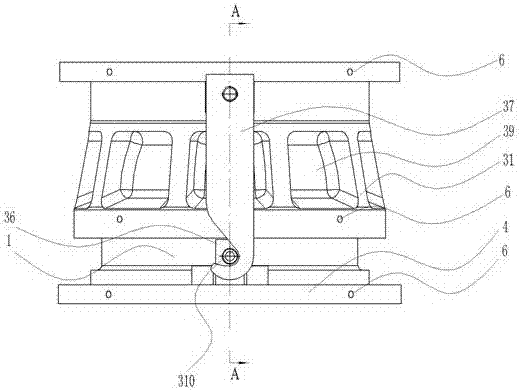

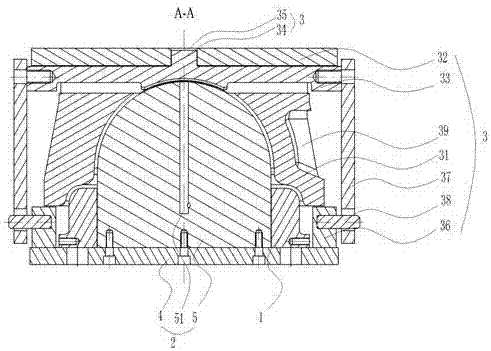

[0056] A hot drawing die used in a hemispherical deep drawing method, such as figure 1 and figure 2 As shown, it includes a punch 2 and a die 3 for forming hemispherical workpieces. The punch 2 includes a pad 4 and a core 5 matching the hemisphere. The core 5 is fixed on the pad 4 by bolts. A blank holder 1 for installing the workpiece blank is also arranged between the punch 2 and the die 3, and the upper platform drives the die 3 to move up and down to realize the drawing and forming of the hemisphere.

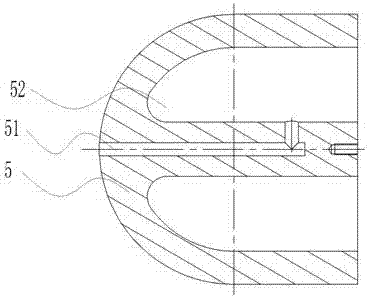

[0057] In the process of deep drawing, the blank material is covered on the mold core, and the upper platform presses down the die to realize deep drawing, and the initial state of the blank material and the mold core is completely bonded, in order to solve this problem questions such as image 3 As shown, in another specific embodiment, the punch 2 is provided with a vent hole 51 penetrating from the top to the bottom.

[0058] Of course, in the actual processing proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com