A method for detecting the content of organic synthetic pigments

A detection method and organic synthesis technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of difficult content determination, difficult extraction, inability to measure sodium aluminum lake of indigo disulfonate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

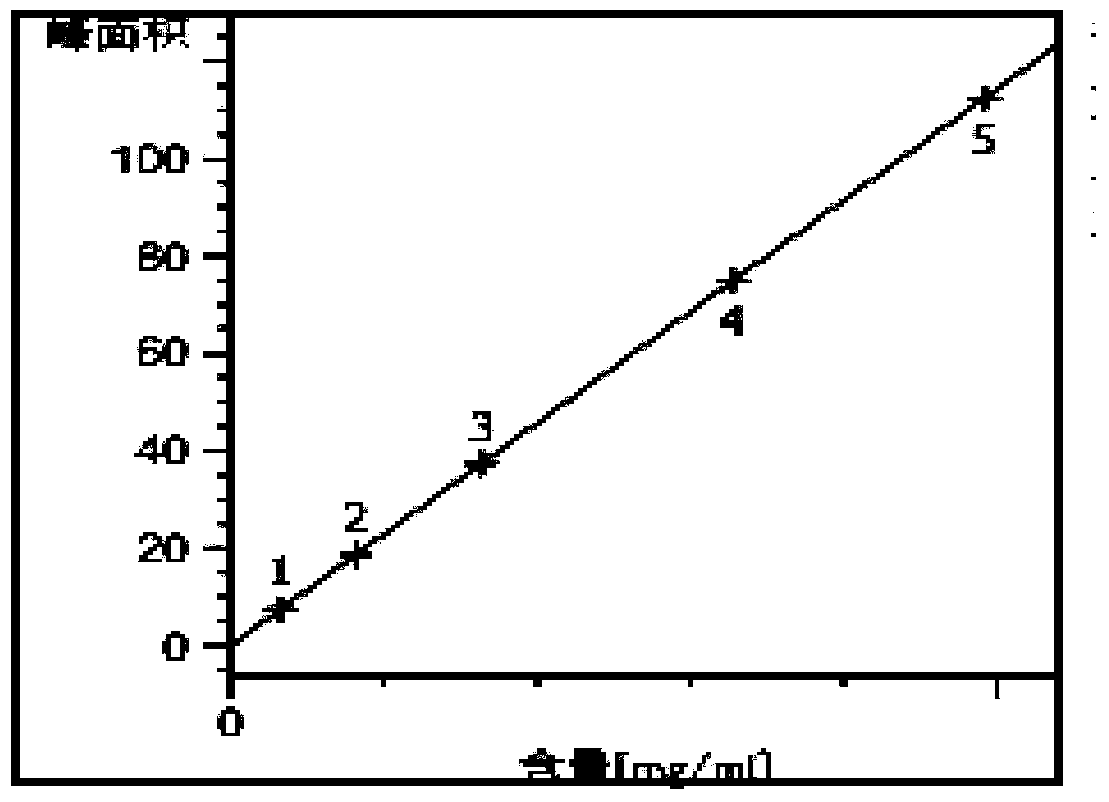

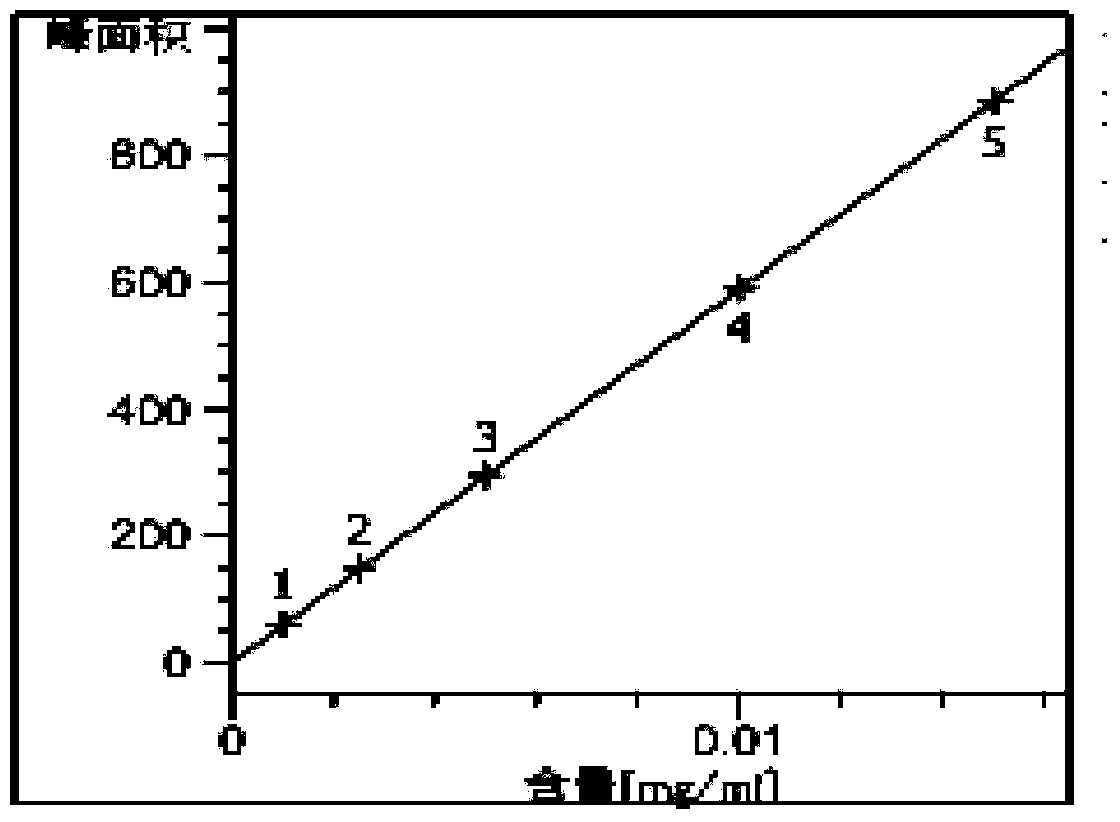

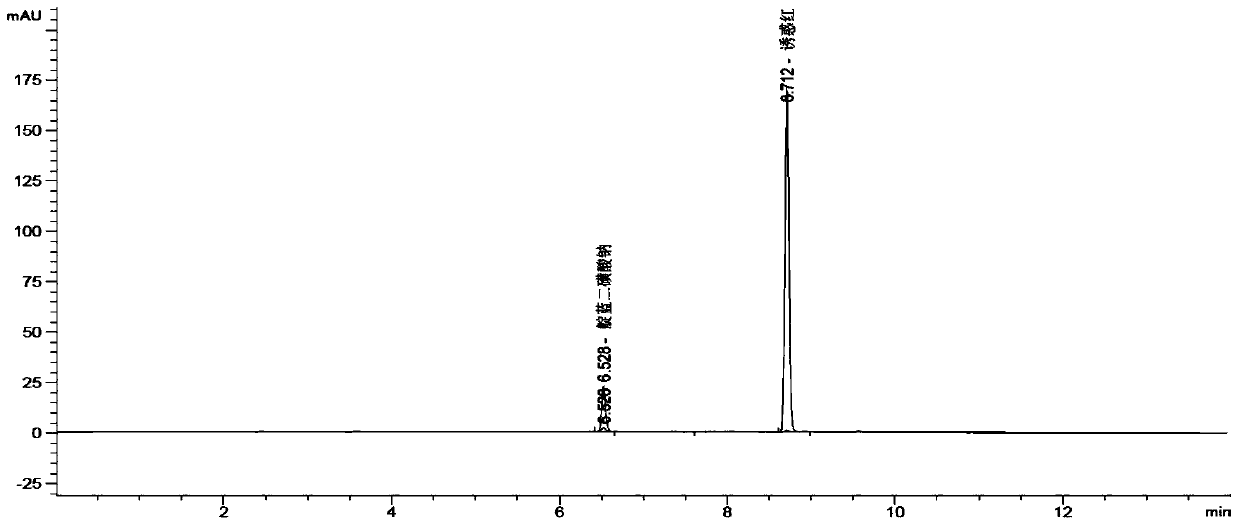

[0066] 1 Principle: Allura red and indigo sodium disulfonate in the sample are extracted with sodium hydroxide solution, and after neutralization with hydrochloric acid solution, allura red and indigo sodium disulfonate are separated by high performance liquid chromatography C18 column, and separated by diode array Detector detection, and quantification by external standard method.

[0067] 2 Instrument: Agilent 1260 high performance liquid chromatography (with diode array detector), or other high performance liquid chromatography with diode array detector.

[0068] 3 Reagents Reagents: sodium hydroxide (AR, ie analytical grade); concentrated hydrochloric acid (AR); ammonium acetate (chromatographically pure); acetonitrile (chromatographically pure); primary water.

[0069] Allura Red, reference substance source: China National Institutes for Food and Drug Control, batch number: 510003-201301, purity: 86.7%;

[0070] Sodium indigo disulfonate, reference source: SIGMA, batch n...

Embodiment 2

[0160] 1 Analysis steps:

[0161] 1.1 Chromatographic conditions:

[0162] Mobile phase: A: 30mmol / L ammonium acetate solution, B: acetonitrile, gradient elution;

[0163] Flow rate: 0.8mL / min;

[0164] Wavelength: Allure Red (500nm), Sodium Indigo Disulfonate (600nm);

[0165] Column temperature: 30°C;

[0166] Injection volume: 5 μL;

[0167] Chromatographic column: PHenomenex Gemini-NX, C18, 250×4.6 mm, 5 μm.

[0168] 1.2 Preparation of control stock solution:

[0169] Accurately weigh 5.7mg of Allura Red reference substance, put it in a 50mL brown volumetric flask, add water to dissolve it and adjust the volume to the mark, and shake well to obtain the stock solution. The stock solution was stored in a refrigerator at 4°C for future use.

[0170] Precisely weigh 8.3mg of indigo sodium disulfonate reference substance, put it in a 50mL brown volumetric flask, add water to dissolve it, adjust the volume to the mark, and shake well to obtain the stock solution. The sto...

Embodiment 3

[0185] 1 Analysis steps:

[0186] 1.1 Chromatographic conditions:

[0187] Mobile phase: A: 100mmol / L ammonium acetate solution, B: acetonitrile, gradient elution;

[0188] Flow rate: 0.5mL / min;

[0189] Wavelength: Allure Red (500nm), Sodium Indigo Disulfonate (600nm);

[0190] Column temperature: 35°C;

[0191] Injection volume: 10μL;

[0192] Chromatographic column: PHenomenex Gemini-NX, C18, 250×4.6 mm, 5 μm.

[0193] 1.2 Preparation of control stock solution:

[0194] Accurately weigh 5.7mg of Allura Red reference substance, put it in a 50mL brown volumetric flask, add water to dissolve it and adjust the volume to the mark, and shake well to obtain the stock solution. The stock solution was stored in a refrigerator at 4°C for future use.

[0195] Precisely weigh 8.3mg of indigo sodium disulfonate reference substance, put it in a 50mL brown volumetric flask, add water to dissolve it, adjust the volume to the mark, and shake well to obtain the stock solution. The st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| correlation coefficient | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com