A kind of phospho-alumina sol and preparation method and application thereof, catalytic cracking catalyst and preparation method thereof

A technology of aluminum sol and sol, applied in the field of catalytic cracking catalyst and its preparation, can solve problems such as waste, and achieve the effects of simple process, high pH value and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The method for preparing aluminum sol of the present invention can reduce the usage amount of hydrochloric acid, reduce the addition amount of chloride ions, reduce the damage of free acid to the properties of aluminum sol, improve the activity of aluminum sol, and at the same time avoid the pH value of aluminum sol caused by excessive hydrochloric acid If it is too low, it will damage the molecular sieve and affect the catalyst activity.

[0050] In the present invention, the process of the first reaction and the second reaction is accompanied by stirring, and the process of the first reaction and the second reaction ends when the stirring is stopped. The time for the first reaction and the second reaction described below is the time when stirring is continued.

[0051] According to a preferred embodiment of the present invention, the temperature of the first reaction is 50-80°C.

[0052] According to a preferred embodiment of the present invention, the temperature of...

Embodiment approach

[0068] According to a preferred embodiment of the present invention, the method further includes: before performing step (2), standing the first contacted mixture at room temperature for 1-30 hours, preferably standing for 2-6 hours. The static means that after the agitation accompanying the first contact is stopped, the mixture after the first contact is left in a non-stirred state.

[0069] According to the method of the present invention, normal temperature refers to room temperature, for example, generally 0-40°C.

[0070] According to a preferred embodiment of the present invention, the conditions for the first contact further include: relative to 1 mol of hydrochloric acid, the amount of metal aluminum used is 0.8 mol-1.3 mol.

[0071] According to a preferred embodiment of the present invention, the conditions of the first contact further include: the first contact time is 2-5 hours.

[0072] According to a preferred embodiment of the present invention, the conditions ...

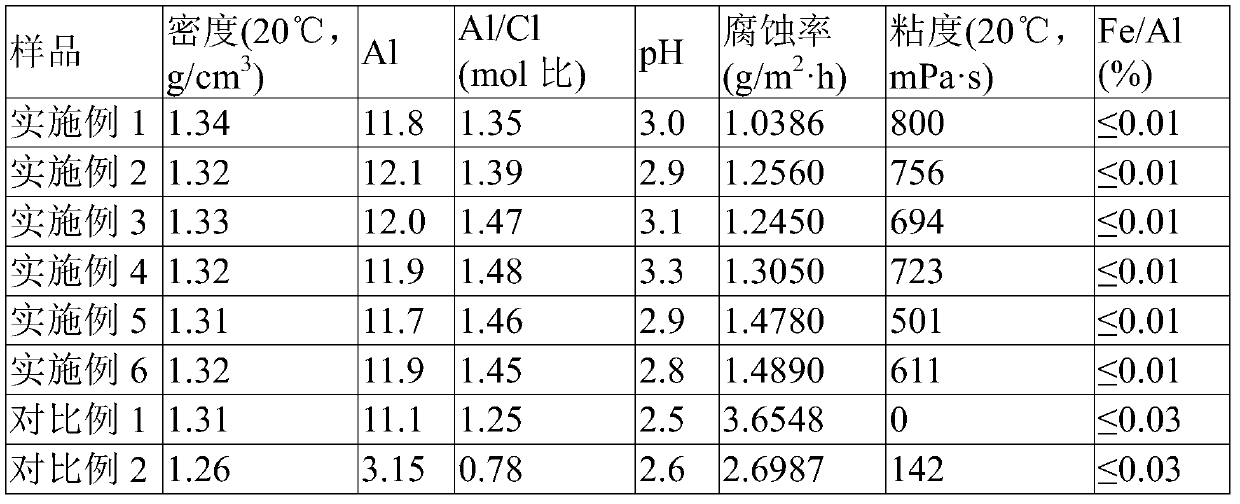

Embodiment 1

[0123] (1) Carry out the first contact with 0.8mol metal aluminum (China Aluminum Corporation) and 1mol (HCl) hydrochloric acid, control the temperature of the first contact process to be 50°C, the first contact time is 3h, and the initial concentration of hydrochloric acid used is 32 wt. %;

[0124] (2) The mixture after the first contact was left at room temperature at 20°C for 6 hours, and then mixed with γ-Al 2 o 3 (Shandong Aluminum Plant) and η-Al 2 o 3 (Shandong Aluminum Works) carries out the second contact, the second contact temperature is 30 ℃, the second contact time is 4h, the gamma-Al calculated as aluminum 2 o 3 , η-Al in aluminum 2 o 3 The molar ratio to the metal aluminum in step (1) is 0.05:0.05:1. The physical and chemical properties of aluminum sol are listed in Table 1.

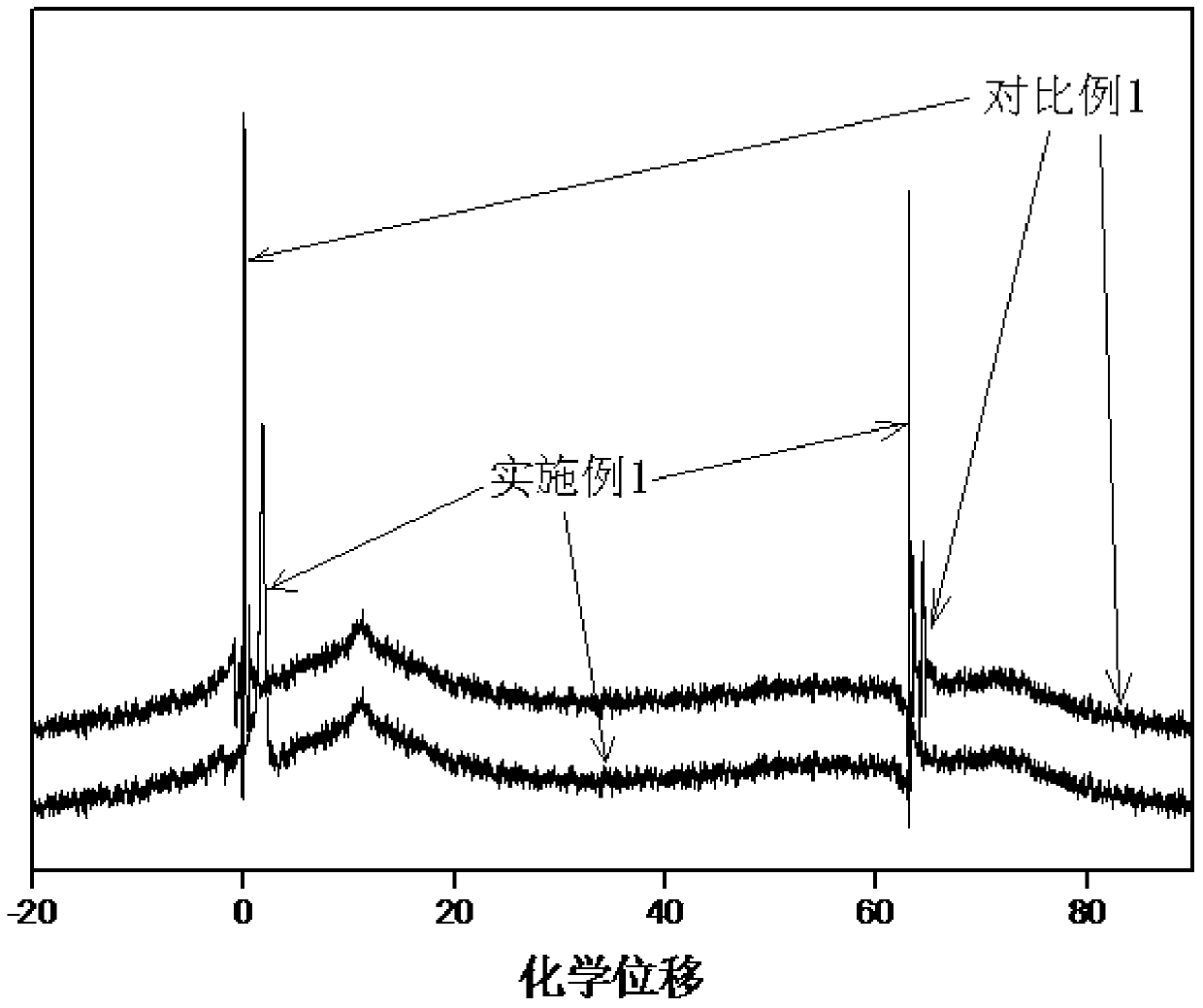

[0125] aluminum sol 27 Al NMR determination, spectrogram see figure 1 , where the peak height and peak area of the signal peak at the chemical shift of 0 to 3 are low and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com