Steam condensate waste heat recovery device

A waste heat recovery device and a technology for steam condensing water, applied in the field of waste heat recovery, can solve the problems of poor recovery efficiency, low heat transfer coefficient and large equipment, and achieve the effects of energy saving, high self-evaporation efficiency and complete heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

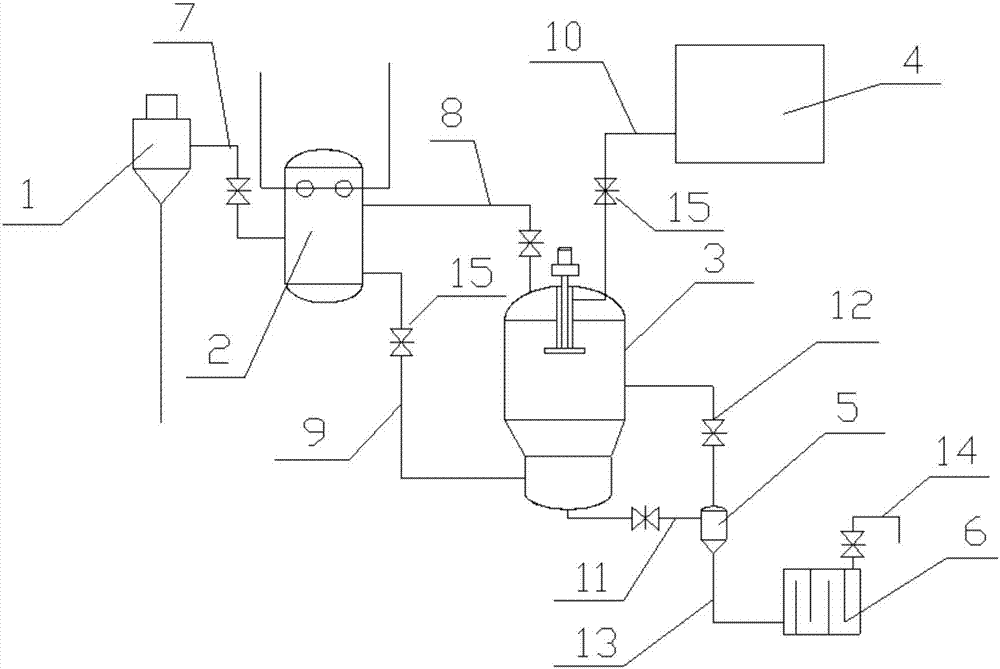

[0016] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0017] Such as figure 1 As shown, a condensate waste heat recovery device includes a vacuum condenser 1, a heater 2, a centrifugal steam diffuser 3, a water tank 4, an equal pressure drainage tank 5 and a multistage drainer 6, and the vacuum condenser 1 The bottom of the heater 2 communicates with the bottom of the heater 2 through the ammonia pipe 7; The lower part communicates with the first drain pipe 9 ; the upper part of the centrifugal steam diffuser 3 communicates with the water tank 4 through a connecting pipe 10 .

[0018] Vacuum condenser 1 is connected to high-temperature condensate water, and self-evaporating steam is continuously generated under negative pressure conditions, and the self-evaporating st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com