Preparation method of monolayer molybdenum disulfide thin film

A single-layer molybdenum disulfide, thin film technology, applied in coating, gaseous chemical plating, metal material coating process and other directions, can solve the problem that the evaporation temperature and growth temperature of molybdenum source cannot be controlled separately, the number of layers varies widely, and Obtaining large-area molybdenum disulfide films and other problems to achieve the effect of avoiding high nucleation density and reducing nucleation density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A kind of preparation method of monolayer molybdenum disulfide film of the present invention,

[0027] A preparation method of a monolayer molybdenum disulfide thin film, comprising the following steps:

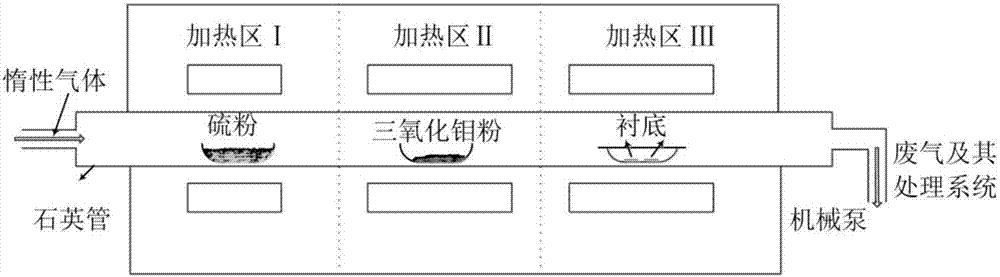

[0028] Step 1, by using a vacuum tube furnace to set three temperature zones, place the sulfur powder in the first temperature zone; put the molybdenum trioxide powder in the second temperature zone; Three temperature zones;

[0029] Step 2, passing carrier gas to the vacuum tube furnace;

[0030] Step 3, the first heating stage: heat the second temperature zone to 150-350°C, heat the third temperature zone to 150-350°C, and keep for 60-180min;

[0031] Step 4, the second heating stage: heat the second temperature zone to 580-800°C and keep it for 5-20 minutes to obtain gaseous MoO 3-x , where 0

[0032] Step 5, the third heating stage: heat the first temperature zone to 130-220°C and keep it ...

Embodiment 1

[0046] Step 1, such as figure 1 As shown, by using a vacuum tube furnace to set three temperature zones, the sulfur powder with a purity of 99.99% is placed in a corundum boat and placed in one temperature zone; the molybdenum trioxide powder with a purity of 99.99% is placed in a corundum boat and placed in a The second temperature zone, where the mass ratio of sulfur powder to molybdenum trioxide powder is: 1:20; select the C-face sapphire as the substrate, and clean the substrate; after drying, place it in a quasi-closed crucible and place it in the three temperature zone .

[0047]Step 2, feed the carrier gas into the vacuum tube furnace: high-purity nitrogen, and the flow rate of the feed carrier gas is 100ccm;

[0048] Step 3, the first heating stage: heat the second temperature zone to 150°C, heat the third temperature zone to 150°C, and keep for 180 minutes; the heating rate of the second temperature zone and the third temperature zone is 5°C / min;

[0049] Step 4, th...

Embodiment 2

[0053] Step 1, such as figure 1 As shown, by using a vacuum tube furnace to set three temperature zones, the sulfur powder with a purity of 99.99% is placed in a corundum boat and placed in one temperature zone; the molybdenum trioxide powder with a purity of 99.99% is placed in a corundum boat and placed in a The second temperature zone, where the mass ratio of sulfur powder to molybdenum trioxide powder is: 1:50; select the C-face sapphire as the substrate, and clean the substrate; after drying, place it in a quasi-closed crucible and place it in the three temperature zone .

[0054] Step 2, feed the carrier gas into the vacuum tube furnace: high-purity nitrogen, and the flow rate of the feed carrier gas is 100ccm;

[0055] Step 3, the first heating stage: heat the second temperature zone to 200°C, heat the third temperature zone to 200-150°C, and keep for 100 minutes; the heating rate of the second temperature zone and the third temperature zone is 10°C / min;

[0056] Step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com