A method for synchronous desulfurization of molten steel and slag in rh vacuum furnace for non-oriented silicon steel

A technology of oriented silicon steel and vacuum furnace, which is applied in the field of simultaneous desulfurization of molten steel and slag in RH vacuum furnace of non-oriented silicon steel, can solve the problem of a large amount of sulfur returning to molten steel, reduce the cost of steelmaking, increase the desulfurization reaction interface, and reduce T.Fe The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

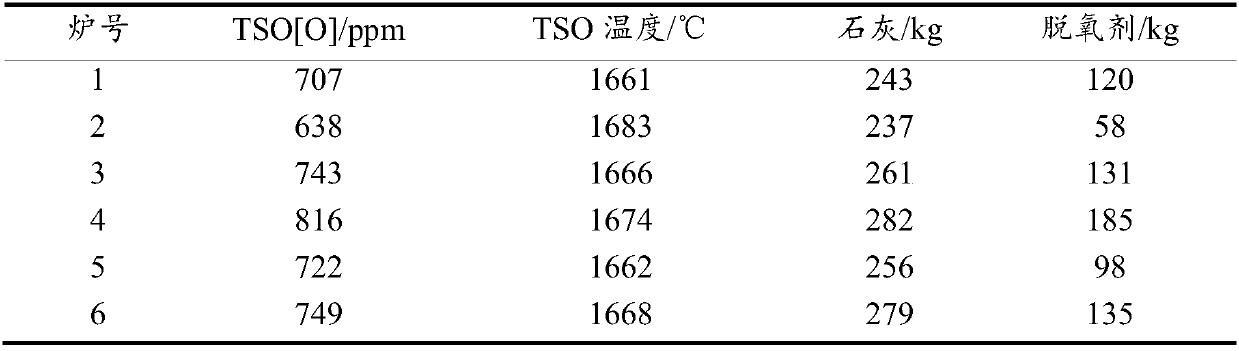

[0037] This implementation discloses a technical scheme adopted by a method for synchronous desulfurization of molten steel and slag in a RH vacuum furnace for non-oriented silicon steel:

[0038] (1) The sulfur content of molten iron after deep desulfurization is lower than 0.0015%, and the slag after desulfurization is removed at the same time;

[0039] (2) The converter uses clean raw and auxiliary materials to reduce the resulfurization of molten steel. Clean raw and auxiliary materials mainly include clean scrap steel, lime, light-burned dolomite, pellets, magnesium balls, sludge balls and other high-sulfur content auxiliary materials are strictly prohibited; converter tapping When the temperature is higher than 1650°C, the slag-stopping cone is used to stop the slag during the tapping process, and the slag is strictly controlled, and the low-carbon steel slag surface deoxidizer and lime are added according to the following methods:

[0040] m 1 =(x [O] -0.06%)×10 6 ·η...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com