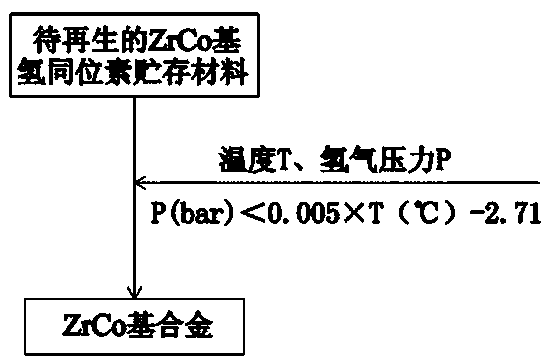

A method for regenerating zrco-based hydrogen isotope storage materials

A hydrogen isotope and hydrogen technology, applied in chemical instruments and methods, hydrogen, non-metallic elements, etc., can solve the problems of difficult hydrogen isotope recovery, complex regeneration process, high regeneration cost, etc., and achieve fast hydrogen release rate and high hydrogen release capacity , The effect of low regeneration cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

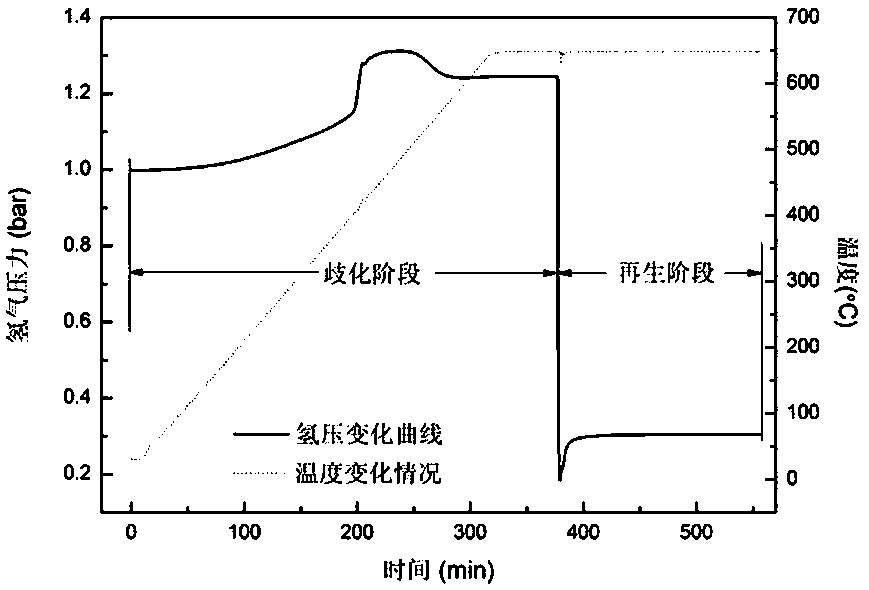

[0030] (1) ZrCo-based alloy disproportionation treatment: first weigh the activated ZrCo-based alloy and put it into the reactor of the Sievert-type test system, then fill the reactor with an initial hydrogen pressure of 1 bar, and then charge it at 2 °C / The heating rate of min can be used to disproportionate the ZrCo-based alloy by raising the temperature of the reactor to 650°C to obtain a disproportionated sample.

[0031] At the same time, the hydrogen pressure and temperature change curve in the reactor during the entire disproportionation process of the ZrCo-based alloy can also be obtained (that is, the hydrogen pressure and temperature change curve in the disproportionation stage of the ZrCo-based alloy), such as figure 2 shown, and, by figure 2 It can be seen that the hydrogen pressure in the reactor first increased and then decreased during the heating process, showing the remarkable characteristics of the disproportionation of the ZrCo-based alloy;

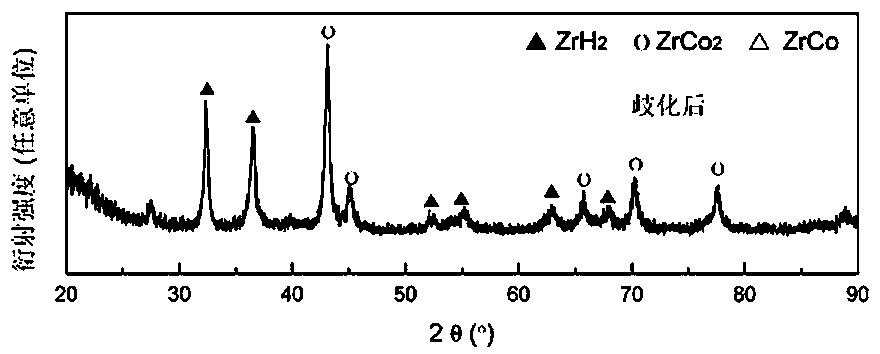

[0032] The ...

Embodiment 2

[0037] In this example, except that the hydrogen pressure in the reactor in step (2) is adjusted to 0.3 bar, and the regeneration reaction time is 200 minutes, the rest are the same as in Example 1.

[0038] In this embodiment, the hydrogen pressure and temperature change curves of the ZrCo-based alloy disproportionation stage obtained in step (1) are recorded as Figure 5 Shown, obtain the XRD pattern record of disproportionation sample as Figure 6 shown; and, the hydrogen pressure and temperature change curves of the ZrCo-based alloy regeneration stage obtained in step (2) were recorded in Figure 5 Among them, obtain the XRD pattern record of disproportionation sample as Figure 7 shown.

Embodiment 3

[0040] (1) ZrCo-based alloy disproportionation treatment: first weigh the activated ZrCo-based alloy and put it into the reactor of the Sievert-type test system, then fill the reactor with an initial hydrogen pressure of 2 bar, and then charge it at 5 °C / The temperature rise rate of min can be used to disproportionate the ZrCo-based alloy by raising the temperature of the reactor to 600°C to obtain a disproportionated sample.

[0041] (2) Regeneration of the disproportionated ZrCo-based alloy: keep the reactor containing the sample at 600 °C, adjust the hydrogen pressure to 0.1 bar, and then keep the reactor at this temperature and hydrogen pressure for 150 min. That is, the regeneration is completed, and a ZrCo-based alloy that has been regenerated is obtained. Among them, the relationship between hydrogen pressure and temperature in the regeneration process of the disproportionated ZrCo-based alloy satisfies 0.1<0.005×600-2.71=0.29;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com