Full-automatic winding machine for multiple filter papers

A winding machine, fully automatic technology, applied in the direction of filtration and separation, fixed filter element filter, sending objects, etc., can solve the problems of unable to meet the production demand, high labor intensity, low production efficiency, etc., and achieve a wide range of tape selection , Improve the winding quality and facilitate the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

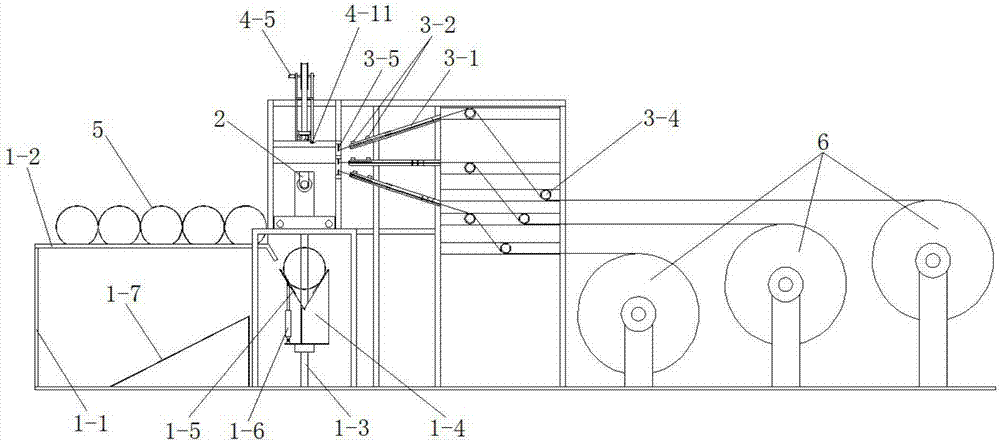

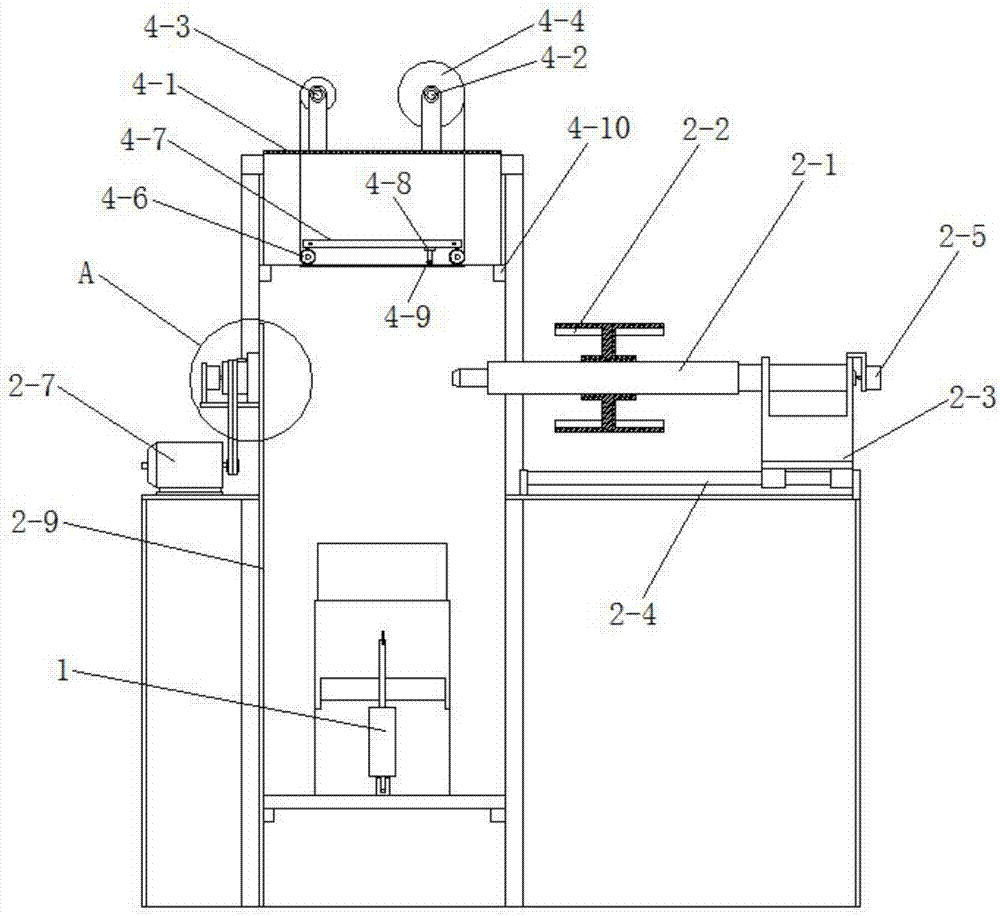

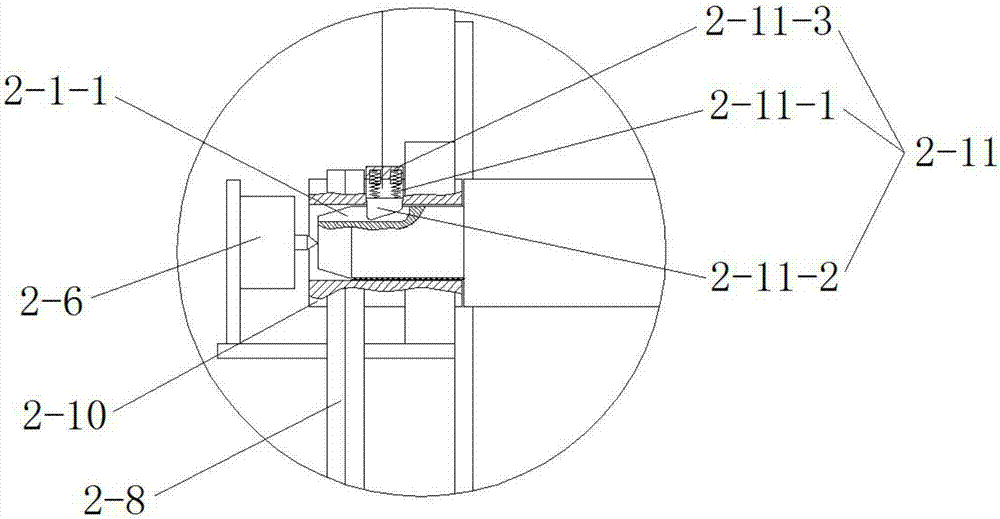

[0037] See Figure 1 to Figure 4 , The multi-filter paper automatic winding machine of the present embodiment includes a filter core skeleton conveying and positioning mechanism 1, a skeleton tensioning and winding mechanism 2, a filter paper conveying positioning cutting mechanism 3 and a tape conveying and pasting mechanism 4.

[0038]The filter element frame conveying and positioning mechanism 1 sends the filter element frame 5 to the frame tensioning winding mechanism 2 . Skeleton expansion The winding mechanism 2 expands the filter core frame 5 and drives the filter core frame 5 to rotate. There are three filter paper conveying positioning and cutting mechanisms 3, each of which is equipped with a filter paper roll 6. The filter paper conveying positioning cutting mechanism 3 sends the filter paper on the corresponding filter paper roll 6 sequentially to the filter core skeleton 5 expanded by the skeleton tension winding mechanism 2 . The tape conveying and sticking mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com