A system and method for constructing a three-dimensional micro-nano-scale prefabricated vascular network of bone tissue

A technology of micro-nano scale and construction method, applied in tissue regeneration, processing and manufacturing, manufacturing tools, etc., can solve problems such as can not be effectively solved, and achieve the effect of easy material, material acquisition, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

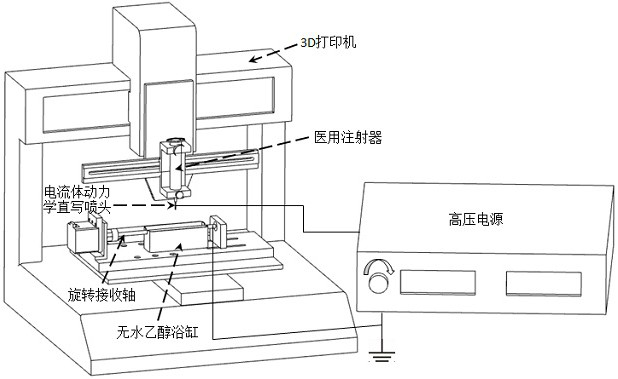

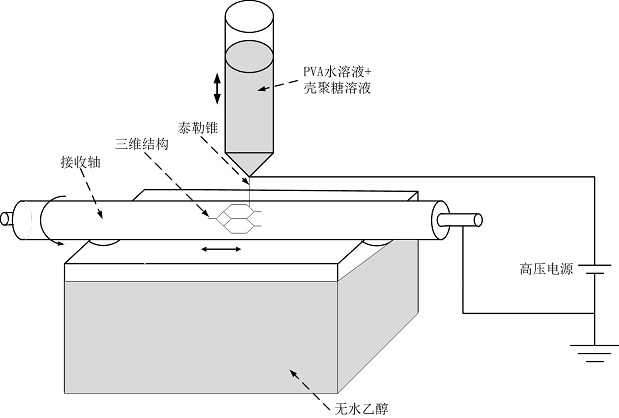

[0031] In this embodiment, see Figure 1 ~ Figure 3 , A method for constructing a three-dimensional micro-nano-scale prefabricated blood vessel network of bone tissue, including the following steps:

[0032] a. Use a blend of PVA aqueous solution and chitosan solution as the sacrificial material, and use anhydrous ethanol as the initiating agent and the coordinated movement of the aluminum alloy shaft as the receiving device, and connect the positive electrode of the high-voltage power supply to the 3D printing nozzle. The wire is connected with the rotating receiving shaft. When there is voltage, the fiber filament formed connects the nozzle with the rotating receiving shaft to form a closed path. The direct writing process can be controlled by shortening the distance between the nozzle and the rotating receiving shaft;

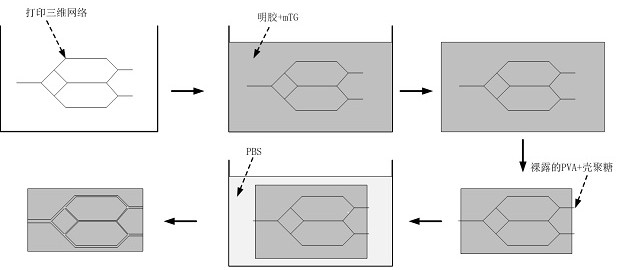

[0033] b. Replace the nozzle in step a with a 20G needle, enter the coding program of the sacrificial structure in the 3D printer and run it. Under the action of...

Embodiment 2

[0038] This embodiment is basically the same as the first embodiment, and the special features are:

[0039] In this embodiment, a method for constructing a three-dimensional micro-nano-scale prefabricated blood vessel network of bone tissue, using PGA as the polymer I material, includes the following steps:

[0040] a. Use a blend of PGA aqueous solution and chitosan solution as the sacrificial material, and use anhydrous ethanol as the initiating agent and a coordinated movement aluminum alloy shaft as the receiving device. Connect the positive electrode of the high-voltage power supply to the 3D printing nozzle. The wire is connected with the rotating receiving shaft. When there is voltage, the fiber filament formed connects the nozzle with the rotating receiving shaft to form a closed path. The direct writing process can be controlled by shortening the distance between the nozzle and the rotating receiving shaft;

[0041] b. Replace the nozzle in step a with a 20G needle, enter t...

Embodiment 3

[0045] This embodiment is basically the same as the foregoing embodiment 1, and the special features are:

[0046] In this embodiment, a method for constructing a three-dimensional micro-nano-scale prefabricated vascular network of bone tissue, the hydrogel adopts gelatin loaded with human bone marrow mesenchymal stem cells, and includes the following steps:

[0047] a. This step is the same as in Example 1;

[0048] b. This step is the same as in Example 1;

[0049] c. After the three-dimensional micro-nano-scale sacrificial module prepared in step b is formed, a layer of liquid paraffin is coated on its surface, and then placed in a 37°C drying oven to dry the paraffin, while 15% gelatin is prepared with deionized water, Place in a 60°C water bath and stir until the gelatin particles are uniformly dissolved and the temperature drops to 30°C. At this time, add mTG enzyme (the mass ratio of gelatin to mTG enzyme is 10:1) to crosslink the gelatin solution. Take out the fifth-generatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com