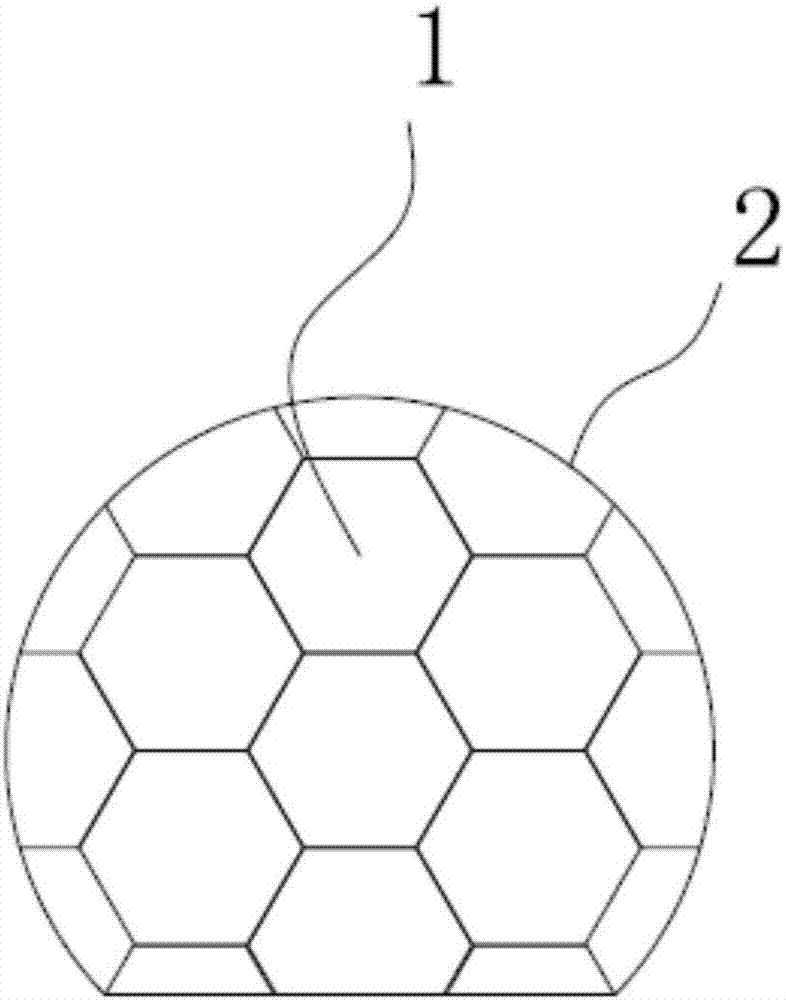

Radar radome and preparation method thereof

A technology of radome and radome, which is applied in the direction of antenna, antenna parts, radiation unit cover, etc., can solve the problems of production staff injury, odor, large dust, low production efficiency, etc., and achieve high production efficiency and mechanical strength High, high porosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

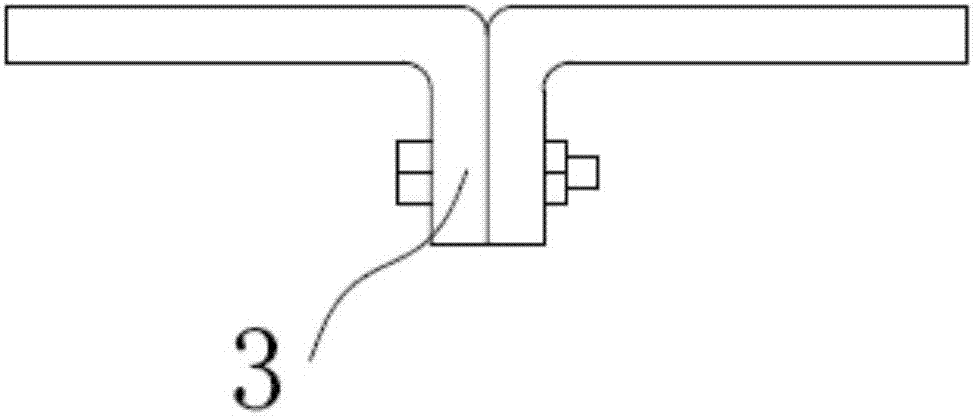

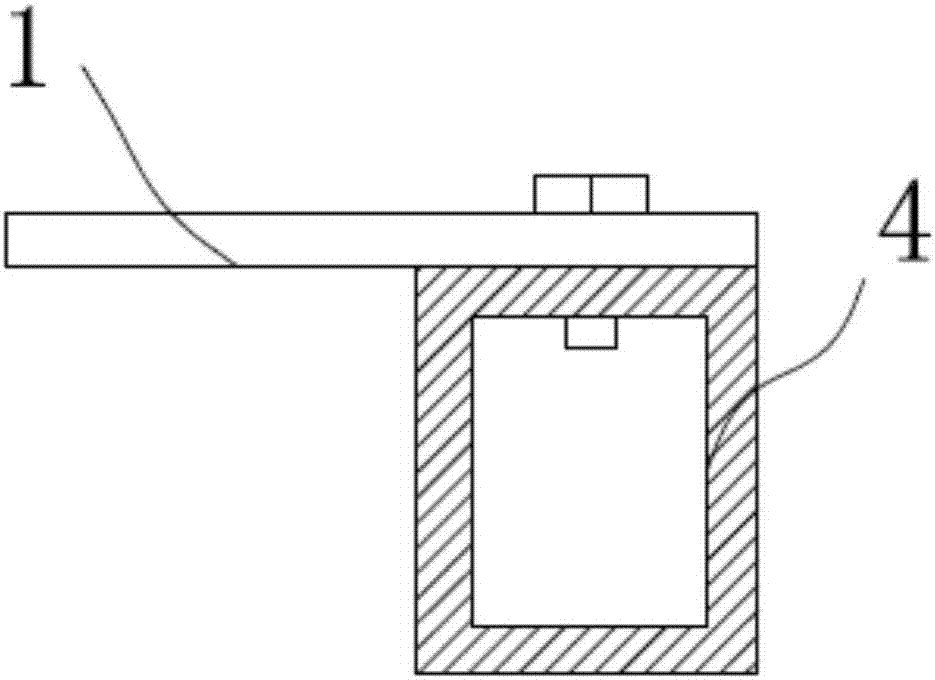

[0038] A method for preparing a radome, comprising the steps of:

[0039] The preparation method of the glass fiber / resin mixed felt layer 5 includes the following steps: drawing glass fiber and resin fiber or glass fiber and resin fiber according to the mass ratio of 1:0.5, uniformly mixing, and then performing opening treatment, carding and forming , cross-laminated, needle-punched into felt, and rolled to obtain a glass fiber / resin mixed felt layer. The first layer of continuous glass fiber reinforced thermoplastic resin composite material 61 and the second layer of continuous glass fiber reinforced thermoplastic resin composite material 62 are sheets obtained by impregnating continuous glass fiber with thermoplastic resin.

[0040] The first layer of continuous glass fiber reinforced thermoplastic resin composite material 61, the glass fiber / resin mixed felt layer 5, and the second layer of continuous glass fiber reinforced thermoplastic resin composite material 62 laid in...

Embodiment 2

[0044] A method for preparing a radome, comprising the steps of:

[0045]The preparation method of the glass fiber / resin mixed felt layer 5 includes the following steps: drawing glass fiber and resin fiber or glass fiber and resin fiber according to the mass ratio of 1:2, uniformly mixing, then performing opening treatment, combing and forming , cross-laminated, needle-punched into felt, and rolled to obtain a glass fiber / resin mixed felt layer. The first layer of continuous glass fiber reinforced thermoplastic resin composite material 61 and the second layer of continuous glass fiber reinforced thermoplastic resin composite material 62 are sheets obtained by impregnating continuous glass fiber with thermoplastic resin.

[0046] The first layer of continuous glass fiber reinforced thermoplastic resin composite material 61, the glass fiber / resin mixed felt layer 5, and the second layer of continuous glass fiber reinforced thermoplastic resin composite material 62 laid in sequen...

Embodiment 3

[0051] A method for preparing a radome, comprising the steps of:

[0052] The preparation method of the glass fiber / resin mixed felt layer 5 includes the following steps: drawing glass fiber and resin fiber or glass fiber and resin fiber according to the mass ratio of 1:1, uniformly mixing, and then performing an opening treatment, combing and forming , cross-laminated, needle-punched into felt, and rolled to obtain a glass fiber / resin mixed felt layer. The first layer of continuous glass fiber reinforced thermoplastic resin composite material 61 and the second layer of continuous glass fiber reinforced thermoplastic resin composite material 62 are sheets obtained by impregnating continuous glass fiber with thermoplastic resin.

[0053] The first layer of continuous glass fiber reinforced thermoplastic resin composite material 61, the glass fiber / resin mixed felt layer 5, and the second layer of continuous glass fiber reinforced thermoplastic resin composite material 62 laid i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com