Quick brake internal expanding brake structure

A braking mechanism, fast technology, applied in the direction of brake actuators, brake parts, brake types, etc., can solve problems such as unstable contact between brake pads and friction plates, unstable braking, and inability to complete braking , to achieve the effect of stable locking state, avoiding potential safety hazards, and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

[0026] The present invention will be described in further detail below by means of specific embodiments:

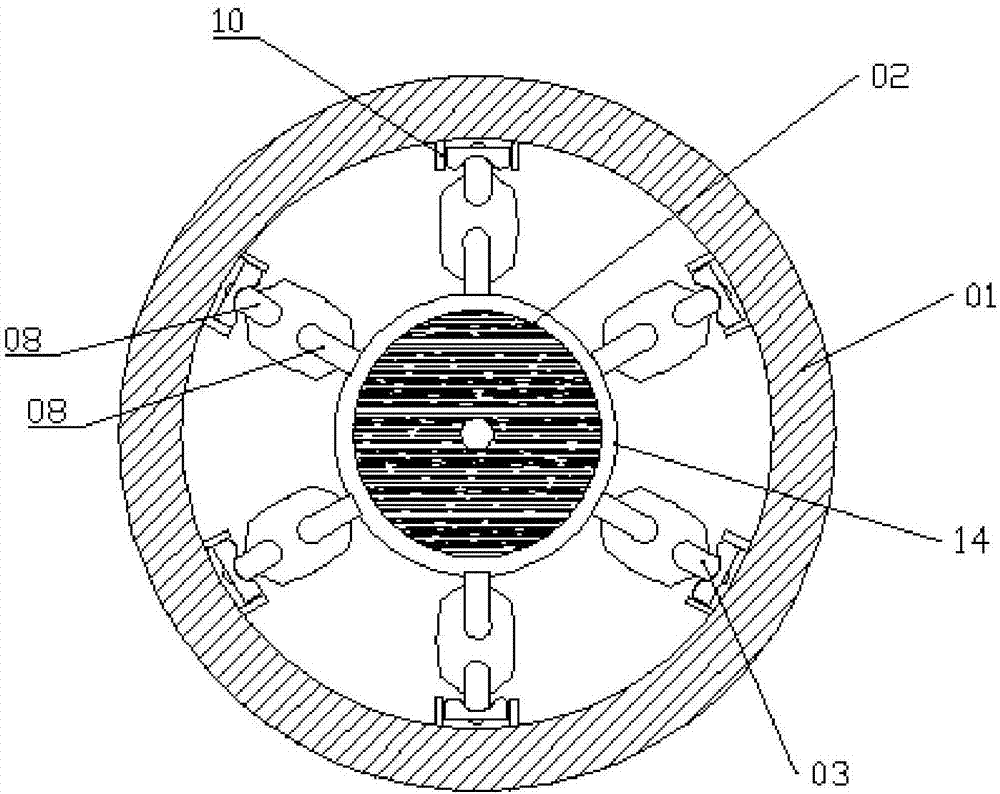

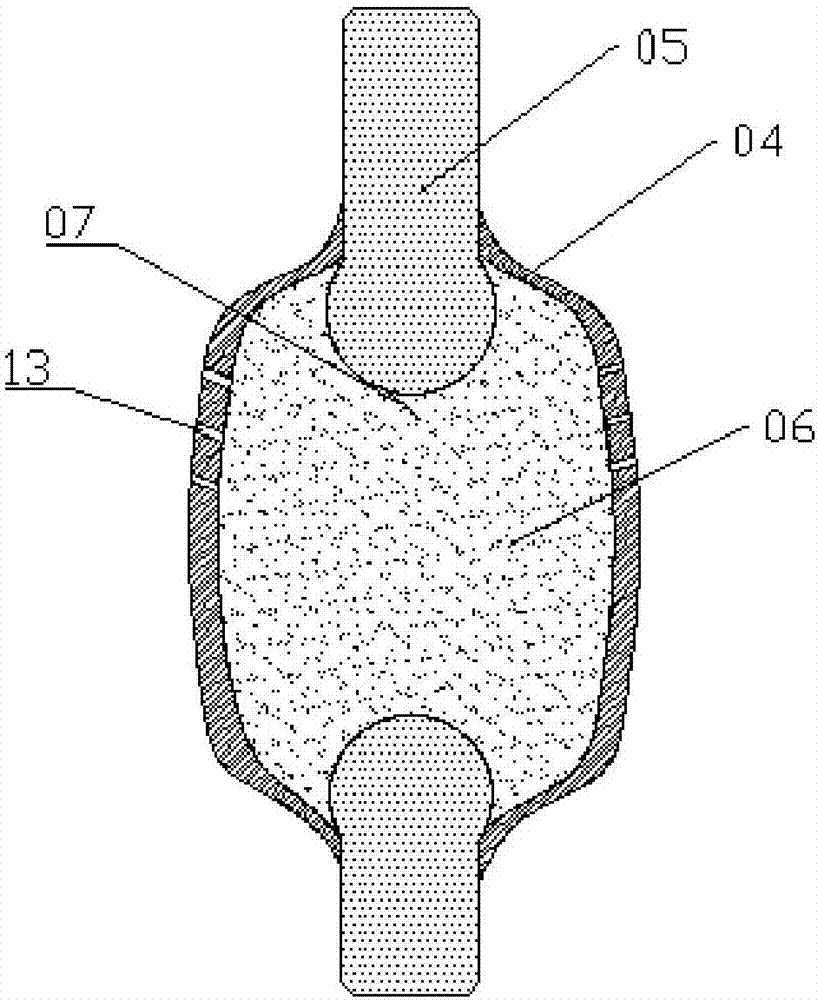

[0027] Such as figure 1 As shown, the present embodiment provides a rapid braking internal expansion brake structure, including a brake disc 01 and a wheel shaft 02 that coincides with the axis of the brake disc 01, and the wheel shaft 02 is fixedly connected with the frame of the car. Between the moving disc 01 and the wheel shaft 02, there are 6 pneumatic brake mechanisms 03 evenly distributed along the inner wall of the brake disc 01 at an equal angle. key, the locking key is fixedly connected to the inner wall of the brake disc 01, and the hub 14 made of flexible and wear-resistant material is provided on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com