A method for preventing ladle sticking slag in refining process

A refining process, ladle technology, applied in steel manufacturing process, manufacturing converter, metal processing, etc., can solve the problems of affecting refining operation, loss of coating, unfavorable continuous production, etc., to improve economic efficiency and improve service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

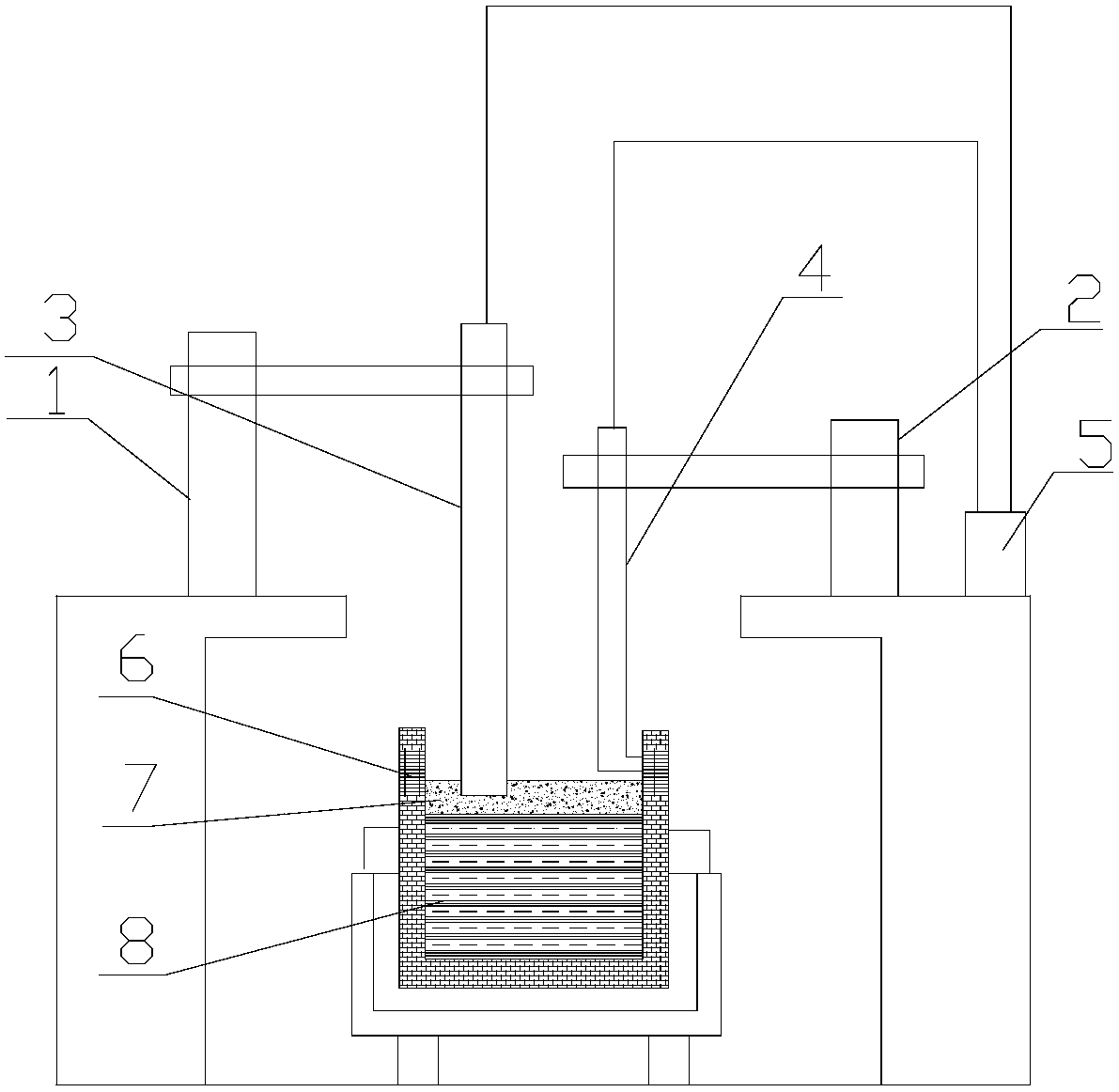

Image

Examples

Embodiment 1

[0026] (1) Converter tapping: After the normal smelting of the converter, the tapping temperature is 1667°C, and the slag blocking treatment is adopted during the tapping process, and the thickness of the slag is 30mm.

[0027] (2) Transport the ladle to the refining position quickly, and the transport time is 8 minutes.

[0028] (3) The ladle is transported to the refining station, and the electrode is immediately lowered to the ladle to ensure that the anode is in contact with the slag and not in contact with the molten steel, and the cathode is in contact with the magnesia carbon brick and not in contact with the slag and molten steel, and then the slag and Apply a stable 20V voltage to the magnesia-carbon bricks for anti-slag treatment. After the ladle arrives at the refining station, the waiting time for the anti-slag treatment is 3 minutes. Bottom blowing gas agitation is carried out during the process.

[0029] (4) Stop blowing gas at the bottom 3 minutes before liftin...

Embodiment 2

[0033] (1) Converter tapping: After the normal smelting of the converter, the tapping temperature is 1680°C, and the slag blocking treatment is adopted during the tapping process, and the thickness of the slag is 35mm.

[0034] (2) Transport the ladle to the refining position quickly, and the transport time is 7 minutes.

[0035] (3) The ladle is transported to the refining station, and the electrode is immediately lowered to the ladle to ensure that the anode is in contact with the slag and not in contact with the molten steel, and the cathode is in contact with the magnesia carbon brick and not in contact with the slag and molten steel, and then the slag and Apply a stable 18V voltage to the magnesia-carbon brick for anti-slag treatment. After the ladle arrives at the refining station, the waiting time for the anti-slag treatment is 4 minutes. Bottom blowing gas agitation is carried out during the process.

[0036] (4) Stop blowing gas at the bottom 3 minutes before lifting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com