Flame-retarding asphalt and preparation method thereof

A technology of asphalt and petroleum asphalt, applied in the field of new road material preparation, can solve the problems of poor smoke suppression, smoke, and poor flame retardant effect of halogen flame retardants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

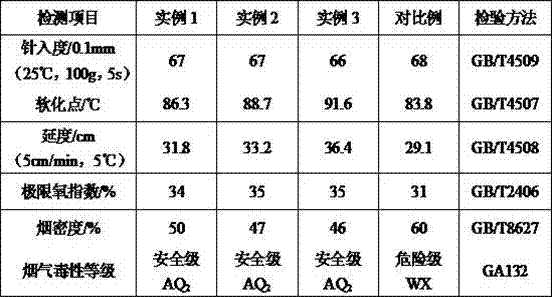

Examples

example 1

[0026]Take 100g of petroleum asphalt and add it to a three-necked flask equipped with a thermometer and a reflux device. Place the three-necked flask in a magnetic stirrer with a digital display, speed measurement, and constant temperature. Add 15g of vinyltrimethoxysilane and 0.1g of diisophenylpropane peroxide to the flask, keep the temperature for 2 hours, then add 300mL of absolute ethanol into the three-necked flask, and move the three-necked flask into an ultrasonic disperser, with a frequency of 35KHz Ultrasonic dispersion for 30 minutes, take out the three-necked flask and put it into a water bath, control the temperature of the water bath to 85°C, then add 0.1g of benzoin dimethyl ether and 15mL of thioglycolic acid into the three-necked flask, stir and mix for 5min, then move the three-necked flask into a UV lamp The reaction was irradiated for 40 minutes. After the reaction, the product was obtained. The product was placed in an oven and dried at 80°C for 3 hours to ...

example 2

[0028] Take 150g of petroleum asphalt and add it to a three-necked flask equipped with a thermometer and a reflux device. Place the three-necked flask in a magnetic stirrer with a digital display, speed measurement, and constant temperature. Add 18g of vinyltrimethoxysilane and 0.2g of lauroyl peroxide to the flask, keep it warm for 2 hours, then add 350mL of absolute ethanol into the three-necked flask, and move the three-necked flask into an ultrasonic disperser for ultrasonic dispersion at a frequency of 38KHz After 35 minutes, take out the three-necked flask and put it into a water bath, control the temperature of the water bath to 90°C, then add 0.2g of benzoin dimethyl ether and 18mL of thioglycolic acid into the three-necked flask, stir and mix for 8min, then move the three-necked flask into the UV lamp for irradiation React for 45 minutes. After the reaction is over, the product is obtained. The product is placed in an oven and dried at 83°C for 3 hours to obtain a drie...

example 3

[0030] Take 200g of petroleum asphalt and add it to a three-necked flask equipped with a thermometer and a reflux device. Place the three-necked flask in a magnetic stirrer with a digital display, speed measurement, and constant temperature. Add 20g of vinyltrimethoxysilane and 0.3g of potassium persulfate into the flask, keep it warm for 3 hours, then add 400mL of absolute ethanol into the three-necked flask, and move the three-necked flask into an ultrasonic disperser, and ultrasonically disperse at a frequency of 40KHz for 40min , take out the three-necked flask and put it into a water bath, control the temperature of the water bath to 95°C, then add 0.3g of benzoin dimethyl ether and 20mL of thioglycolic acid into the three-necked flask, stir and mix for 10min, then move the three-necked flask into the ultraviolet lamp for irradiation reaction 50min, after the reaction is over, the product is obtained, the product is placed in an oven, and dried at 85°C for 4 hours to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com