Preparation method of methyl propanal ethyl phosphonate as glufosinate-ammonium intermediate

A technology of ethyl methylpropionyl phosphonate and ethyl methylpropionyl phosphonate, which is applied in the field of preparation of ethyl methylpropionyl phosphonate, an intermediate of glufosinate-ammonium, and can solve the problem of unzipping process The process is cumbersome, the yield is not very ideal, and it is not easy to recycle, etc., to achieve the effect of wide weeding spectrum, not easy to drift, safe and convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of glufosinate-ammonium intermediate methyl propionyl phosphonate, said preparation method comprising the steps of:

[0033] ①Add 100g of ethyl 3,3-diethoxypropylmethylphosphonate (content: 95%, 0.4mol), 18g of water (1mol) and 3g of sulfonic acid resin into a 500mL four-necked bottle, and stir , heated to 30°C, the measured pH value was 1.5, and kept at constant temperature for 2h;

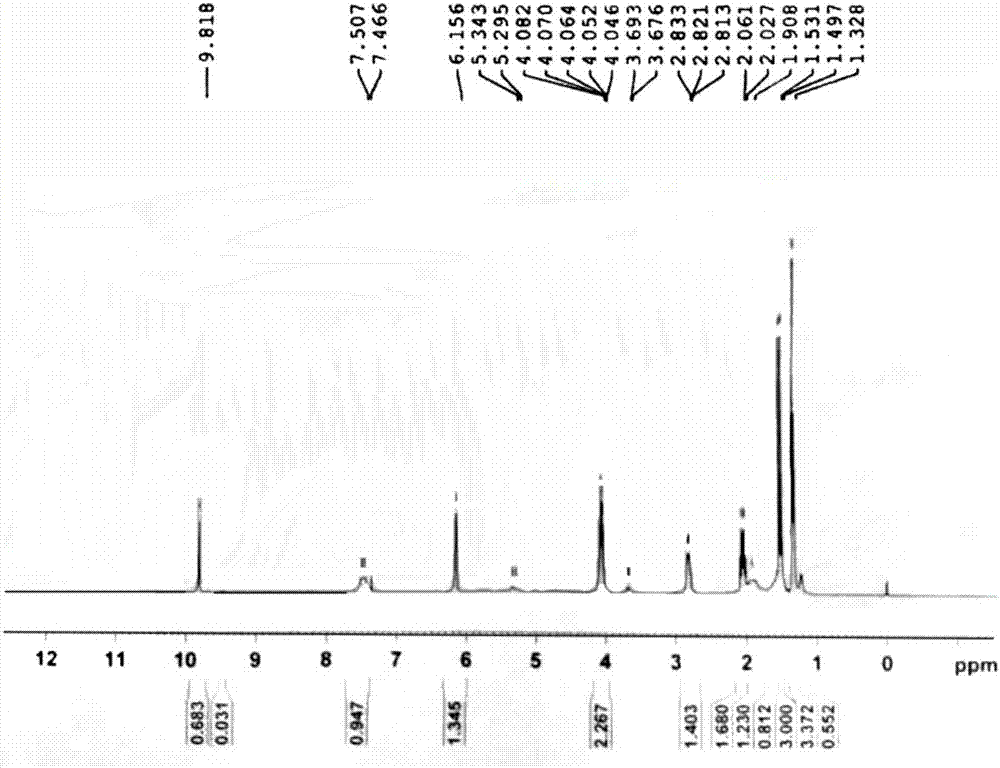

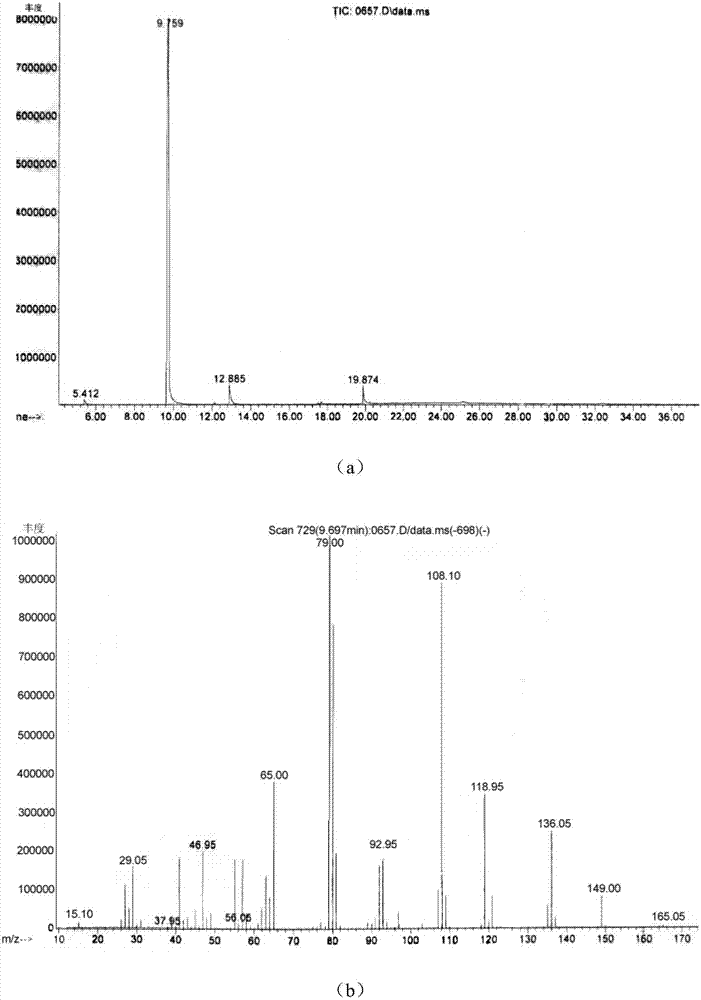

[0034] ②Filtrate the product obtained in step ① to remove the sulfonic acid resin, add the filtrate into a 250mL single-necked bottle, and remove the solvent under reduced pressure by rotary evaporation. Ethyl ester 67.8g, figure 1 and figure 2 Its H NMR spectrum and gas mass analysis chart respectively. After testing, the purity of ethyl methylpropionyl phosphonate was 98% (GC), and the yield was 98.2%.

Embodiment 2

[0036] A preparation method of glufosinate-ammonium intermediate methyl propionyl phosphonate, the difference from Example 1 is: the reaction temperature in step 1. is 50°C; obtain 67g of methyl propionyl phosphonate, It has a purity of 97% (GC) and a yield of 96.2%.

Embodiment 3

[0038] A preparation method of glufosinate-ammonium intermediate methyl propionyl phosphonate, the difference from Example 1 is: the precipitation temperature in step ② is 65°C; obtain ethyl methyl propionyl phosphonate 65.6 g, its purity is 96.2% (GC), and its yield is 95.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com