Preparation method of fluorescent ceramic containing aluminum oxide matrix and related fluorescent ceramic

A technology of fluorescent ceramics and alumina, applied in the preparation of fluorescent ceramics and related fluorescent ceramics field, can solve the problems of low thermal conductivity and low luminous efficiency of fluorescent ceramics, and achieve high thermal conductivity, high luminous efficiency, and improved thermal conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

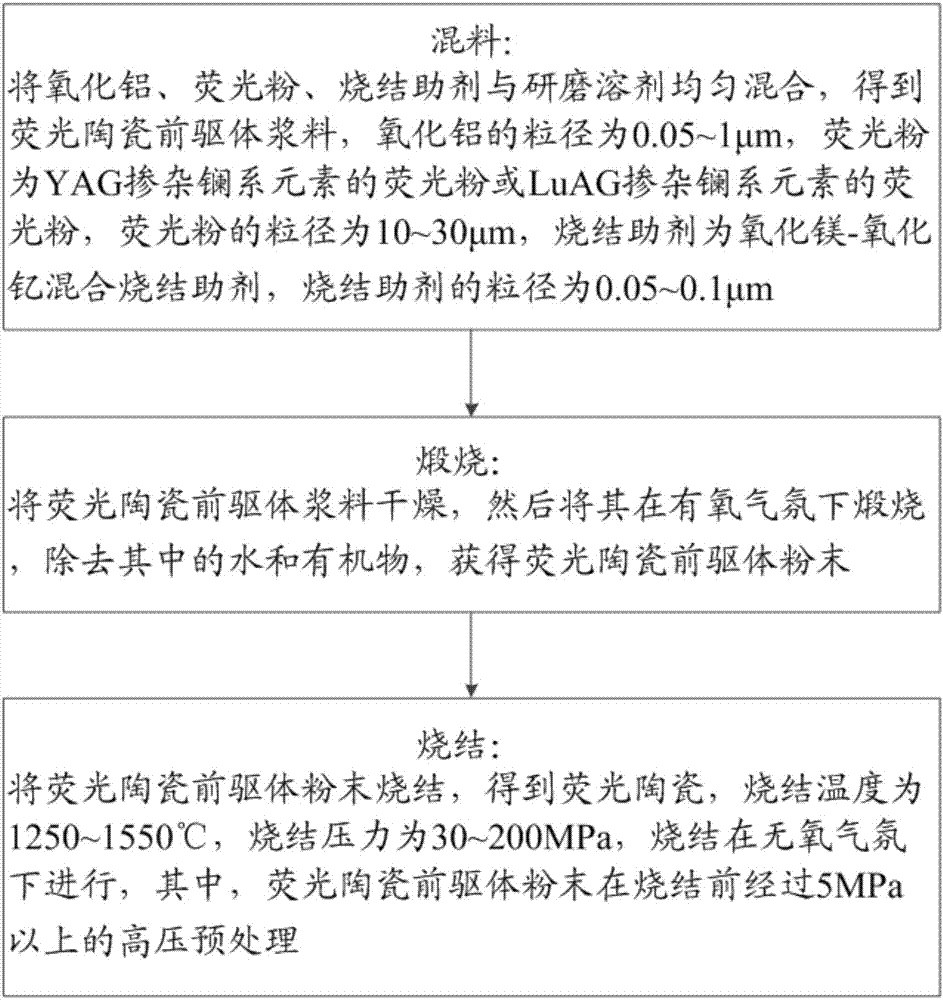

[0024] like figure 1 It is a flowchart of a method for preparing fluorescent ceramics according to an embodiment of the present invention. As shown in the figure, the preparation method includes the following steps in sequence:

[0025] ① Mixing: uniformly mix alumina, fluorescent powder, sintering aid and grinding solvent to obtain fluorescent ceramic precursor slurry. ~0.1μm;

[0026] ②Calcination: Dry the fluorescent ceramic precursor slurry, and then calcinate it in an aerobic atmosphere to remove water and organic matter, and obtain fluorescent ceramic precursor powder;

[0027] ③ Sintering: Sinter the fluorescent ceramic precursor powder to obtain fluorescent ceramics. The sintering temperature is 1250-1550°C, the sintering pressure is 30-200MPa, and the sintering is carried out in an oxygen-free atmosphere. High pressure pretreatment above 5MPa.

[0028] In the mixing step, the first is the selection of raw materials. In this embodiment, ultra-fine alumina powder wi...

Embodiment 1

[0042] The raw materials are high-purity ultra-fine alumina nano-powder with a particle size of 0.08-0.2 μm, high-purity ultra-fine nano-yttrium oxide powder with a particle size of 0.05-0.1 μm, and high-purity ultra-fine nano-magnesia powder with a particle size of 0.05-0.1 μm. 0.05-0.1μm, choose YAG:Ce 3+ Phosphor powder, the particle size is 15-20μm.

[0043] Weigh a certain amount of alumina powder (39.9wt%), yttrium oxide powder (0.05wt%), magnesium oxide powder (0.05wt%) and YAG:Ce 3+ Phosphor powder (60wt%). Put alumina powder, yttrium oxide powder and magnesium oxide powder into a polytetrafluoroethylene ball mill jar, add an appropriate amount of ethanol as a grinding solvent, add an appropriate amount of ceramic dispersant as a dispersant, and use ultra-low loss rate zirconia balls Carry out ball milling for the first time, and the ball milling time is 5h.

[0044] After the first ball milling, add YAG:Ce 3+ The fluorescent powder is put into the ball milling tan...

Embodiment 2

[0049] The raw materials are high-purity ultra-fine alumina nano-powder with a particle size of 0.08-0.2 μm, high-purity ultra-fine nano-yttrium oxide powder with a particle size of 0.05-0.1 μm, and high-purity ultra-fine nano-magnesia powder with a particle size of 0.05-0.1 μm. 0.05-0.1μm, choose YAG:Ce 3+ Phosphor powder, the particle size is 15-20μm.

[0050] Take a certain amount of alumina powder (30wt%), yttrium oxide powder (0.5wt%), magnesium oxide powder (0.5wt%) and YAG:Ce 3+ Phosphor powder (69wt%). Put alumina powder, yttrium oxide powder and magnesium oxide powder into a polytetrafluoroethylene ball mill jar, add an appropriate amount of ethanol as a grinding solvent, add an appropriate amount of ceramic dispersant as a dispersant, and use ultra-low loss rate zirconia balls Carry out the first ball milling, and the ball milling time is 24h.

[0051] After the first ball milling, add YAG:Ce 3+ The fluorescent powder is put into the ball mill tank, and the secon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com