SSZ-13 molecular sieve catalyst as well as preparation method and application thereof

A molecular sieve and catalyst technology, applied in the field of zeolite molecular sieve synthesis, can solve the problems of reducing the use efficiency of nano-zeolite, easy agglomeration, etc., and achieve the effects of inhibiting hydrogen transfer, low aluminum content, and less surface acid sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

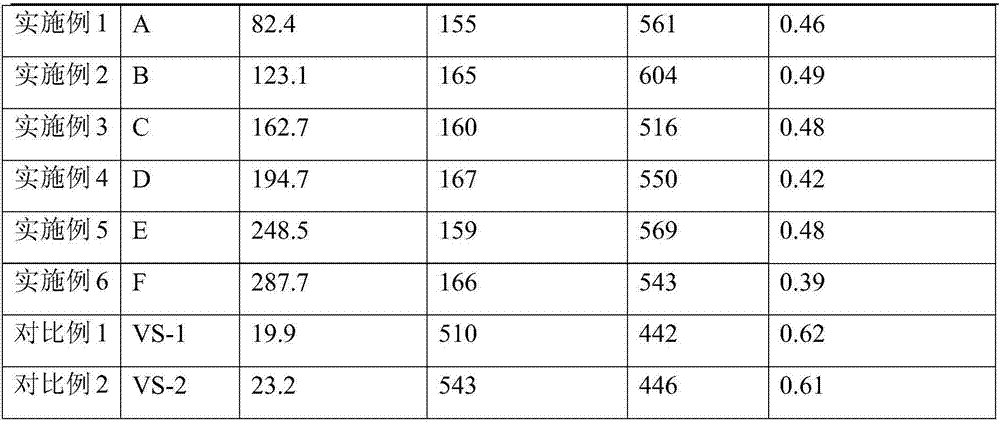

Examples

Embodiment 1

[0027] A kind of SSZ-molecular sieve catalyst is prepared by following method:

[0028] (1) Preparation of molecular sieve powder:

[0029]Dissolve 72.44g NaOH in 600g deionized water at room temperature, then add 1048.30g of N,N,N-trimethyladamantane ammonium aqueous solution (TMADa+, concentration 25wt%), stir well to form solution A, 3.94g NaAlO 2 Dissolve in 125.78g deionized water to form solution B, slowly add solution B to solution A and stir evenly to form solution C, then add 79.94g boric acid to the above solution, and stir until completely dissolved and continue to stir for half an hour, then in Add 122.62g of white carbon black within 1 hour, and keep stirring vigorously. After adding, continue stirring vigorously for 2 hours to obtain a mixed gel. The molar ratio of raw materials is:

[0030] Na 2 O: SiO 2 :Al 2 o 3 :B 2 o 3 :T:H 2 O=0.46:1:0.0118:0.32:0.62:42.0;

[0031] Then transfer the obtained mixed gel to a stainless steel synthesis kettle for cryst...

Embodiment 2

[0037] A kind of SSZ-molecular sieve catalyst is prepared by following method:

[0038] (1) Preparation of molecular sieve powder:

[0039] Dissolve 103.43g NaOH in 400g deionized water at room temperature, then add 3111.07g of N,N,N-trimethyladamantane ammonium aqueous solution (TMADa+, concentration 25wt%), stir to form solution A, and 2.18g quasi Boehmite was dissolved in 110.70g deionized water to form solution B, solution B was slowly added to solution A and stirred evenly to form solution C, then 61.46g H was added to the above solution 3 BO 3 , and stir until completely dissolved and continue to stir for half an hour, then add 122.62g column chromatography silica gel within 1 hour, and keep stirring vigorously, and continue stirring vigorously for 2 hours after adding to obtain a mixed gel, the molar ratio of raw materials is :

[0040] Na 2 O: SiO 2 :Al 2 o 3 :B 2 o 3 :T:H 2 O=0.64:1:0.008:0.246:1.84:79;

[0041] Then transfer the obtained mixed gel to a sta...

Embodiment 3

[0047] A kind of SSZ-molecular sieve catalyst is prepared by following method:

[0048] (1) Preparation of molecular sieve powder:

[0049] Dissolve 67.99g NaOH in 1000g deionized water at room temperature, then add 422.70g of N,N,N-trimethyladamantane ammonium aqueous solution (TMADa+, concentration 25wt%), stir to form solution A, and dissolve 606.62g of water Glass (SiO2, 27.1wt%) was dissolved in 452.35g deionized water to form solution B, solution B was slowly added to solution A and stirred evenly to form solution C, then 54.46g H3BO3 was added to the above solution, and stirred until completely dissolved and Continue to stir for half an hour, then add 1.77g of SB powder within 1 hour, and keep stirring vigorously. After adding, continue stirring vigorously for 2 hours to obtain a mixed gel. The molar ratio of raw materials is:

[0050] Na 2 O: SiO 2 :Al 2 o 3 :B 2 o 3 :T:H 2 O=0.57:1:0.0061:0.218:0.25:66;

[0051] Then transfer the obtained mixed gel to a stain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com