Medical moisture-removing permeable dressing and processing technology thereof

A processing technology and fiber technology, which is applied in the field of medical moisture-absorbing and breathable dressings and their processing technology, can solve the problems of poor moisture-wicking and air-permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

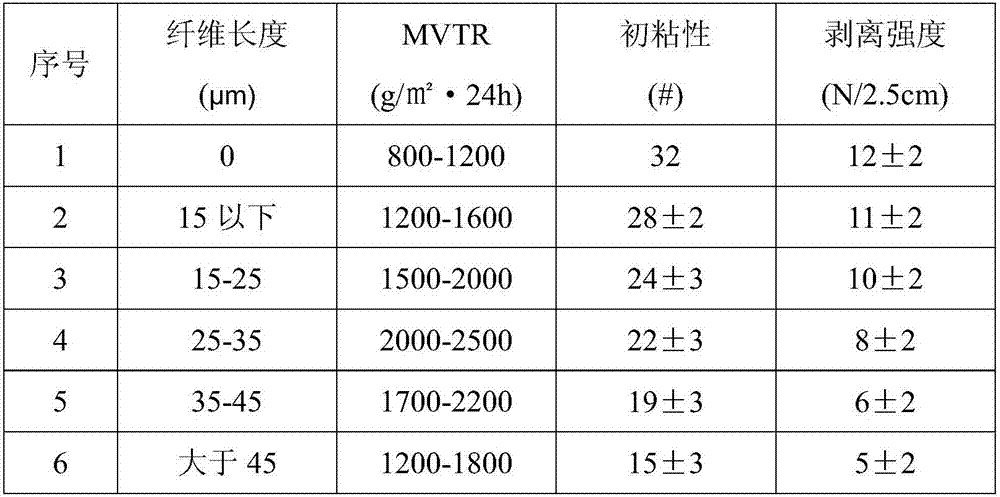

[0023] Example 1: Effects of Fibers of Different Lengths on Moisture Release and Breathability

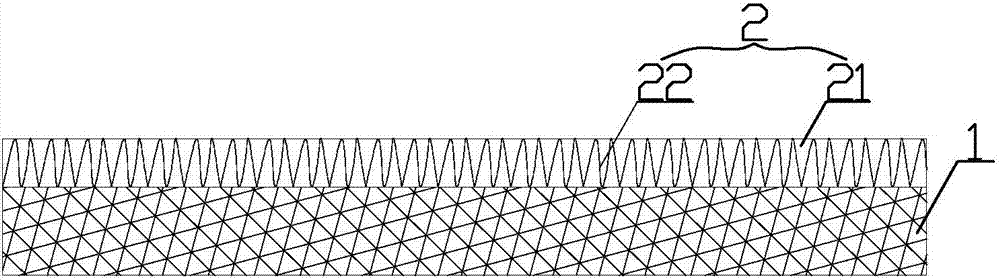

[0024] In this embodiment, the medical dehumidifying breathable dressing is combined with figure 1 , comprising a base material 1 and a composite adhesive layer 2 positioned on the base material 1, wherein the composite adhesive layer 2 is composed of an adhesive body 21 formed of an adhesive and fibers 22 mixed in the adhesive body 21, and the fibers 22 are evenly distributed In the adhesive body 21, in this embodiment, the self-produced ZDS-005 pressure-sensitive adhesive is selected as the adhesive, the self-produced purified water is selected as the soaking agent, and long-staple cotton is selected as the fiber 22. figure 1 The shown is set through the adhesive body 21, and the longer fibers 22 are exposed on the surface of the adhesive body 21, and lie on the upper surface of the adhesive body 21, and the addition percentage of the fiber in the composite adhesive layer is 30%....

Embodiment 2

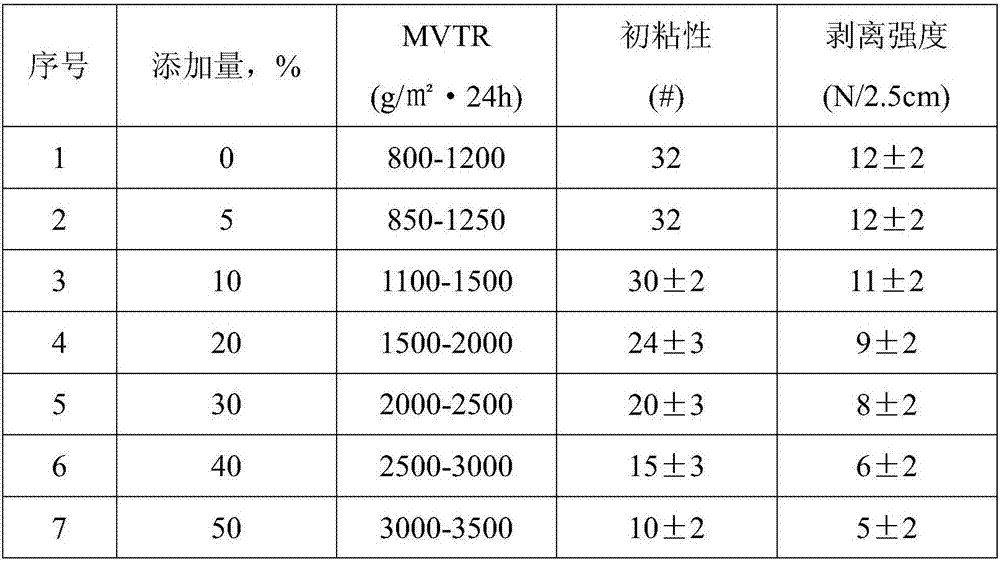

[0033] Example 2: Effect of Fiber Addition on Moisture Release and Air Permeability

[0034] In this embodiment, the medical dehumidifying breathable dressing is combined with figure 1, comprising a base material 1 and a composite adhesive layer 2 positioned on the base material 1, wherein the composite adhesive layer 2 is composed of an adhesive body 21 formed of an adhesive and fibers 22 mixed in the adhesive body 21, and the fibers 22 are evenly distributed In the adhesive body 21, in this embodiment, the self-produced ZDS-005 pressure-sensitive adhesive is selected as the adhesive, the self-produced purified water is selected as the soaking agent, the long-staple cotton is selected as the fiber, and the mass percentage of the fiber added to the composite adhesive layer is gradually increased .

[0035] The processing technology of the above-mentioned dressing is as follows: fiber crushing→soaking→adhesive modification→coating→glue forming→dressing forming.

[0036] Adhes...

Embodiment 3

[0043] Example 3: Effect of Different Fiber Types on Moisture-wicking and Air-permeability

[0044] In this embodiment, the medical dehumidifying breathable dressing is combined with figure 1 , comprising a base material 1 and a composite adhesive layer 2 positioned on the base material 1, wherein the composite adhesive layer 2 is composed of an adhesive body 21 formed of an adhesive and fibers 22 mixed in the adhesive body 21, and the fibers 22 are evenly distributed In the adhesive body 21, in this embodiment, the adhesive is selected from self-produced ZDS-005 pressure-sensitive adhesive, the soaking agent is selected from self-produced purified water, the fiber 22 is selected from long-staple cotton, and the length of the fiber 22 is 20-30 microns, and the fiber 22 The mass percentage added in the composite adhesive layer 2 is 30%.

[0045] The processing technology of the above-mentioned dressing is as follows: fiber crushing→soaking→adhesive modification→coating→glue fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com