A process for engineering fermented biomass feed

A biomass raw material and biomass technology, applied in the technical field of engineering fermented biomass feed, can solve the problems of labor consumption, mildew, shortened fermentation time, high energy cost, etc., so as to reduce production cost, shorten fermentation time, and fermentation time The effect of shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

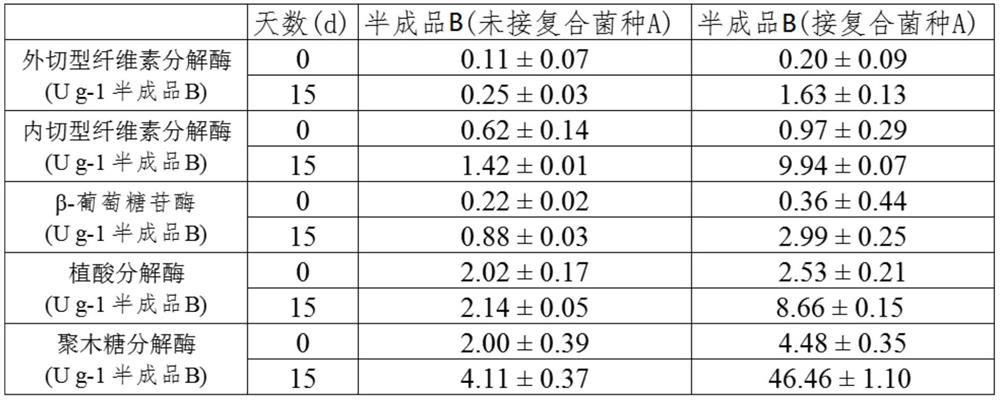

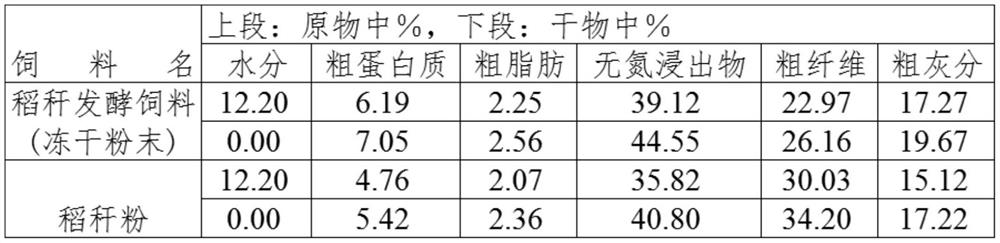

Embodiment 1

[0036] A process for engineering fermented biomass feed, the moisture content of the rice straw is 12.2%, obtained by crushing the rice straw through a pulverizer until the particle size exceeds 0.08mm, and sending it into a mixing mixer; adding 9.8% sterilized Clean water, so that the moisture content of the rice straw powder reaches more than 20%; send the humidified rice straw powder into a tunnel microwave oven for microwave treatment, the frequency is 2600MHz, the power is 1000W, the processing time is 60 seconds, and the processed product is a semi-finished product A; semi-finished product A is sent into the solid-state fermenter and inserted into the compound strain A, the amount of the compound strain A is 5% of the weight percentage of the semi-finished product A added, the culture temperature is controlled at 25~39°C, and the solid-state fermenter is stirred 8 times a day, After 15 days of solid-state aerobic fermentation, the number of live bacteria is greater than 1...

Embodiment 2

[0065] The biomass raw material in the present embodiment adopts soybean meal, and the preparation method of this biomass fermented feed in the present embodiment is as follows:

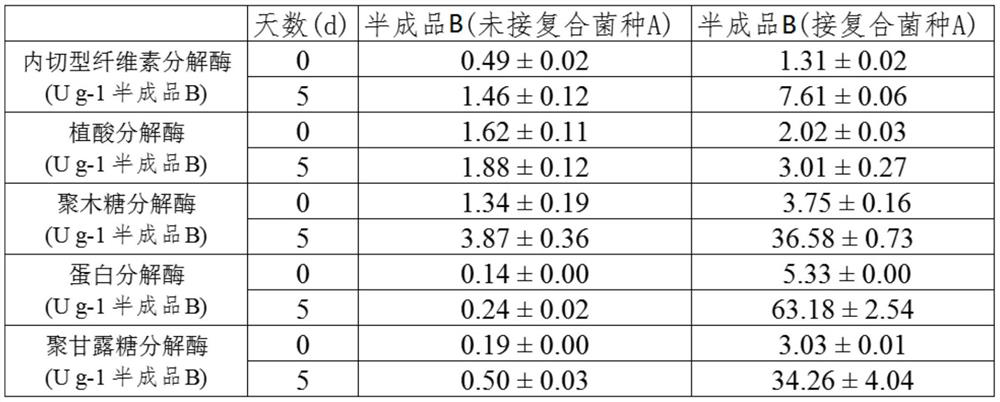

[0066] The moisture content of the soybean meal is 10%, and the soybean meal is crushed through a pulverizer to pass through a 2.5mm sieve, and then sent to a mixing mixer; 18.6% sterilized water is added according to the weight percentage, so that the moisture content of the soybean meal powder reaches 25%; the humidified soybean meal powder The material is sent into the ultrasonic tunnel for ultrasonic treatment, the frequency is 50kHz, and the sound intensity is 8000W / m 2 , the processing time is 120 seconds, and it is a semi-finished product A after processing; The semi-finished product A is sent into a solid-state fermenter and inserted into a compound strain A, and the amount of the compound strain A is to add 10% of the weight percentage of the semi-finished product A, and the culture temperatu...

Embodiment 3

[0099] The difference between this example and Example 1 is that in this example, the rice straw is replaced by distiller's grains. Since distiller's grains and rice straw are both fibrous substances, a process similar to that of the fibrous fermentation in Example 1 can be used. The strains can be selected by adding acid cellulase and silicate degrading strains.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com