One-step preparation of sulfur and nitrogen double-doped cotton-based porous carbon

A cotton, sulfur and nitrogen technology, applied in the field of electrochemistry, can solve the problems affecting the rapid charge and discharge performance of the battery, reduce the charge and discharge specific capacity of the battery, and reduce the utilization efficiency of active sulfur, so as to shorten the preparation time, save time and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

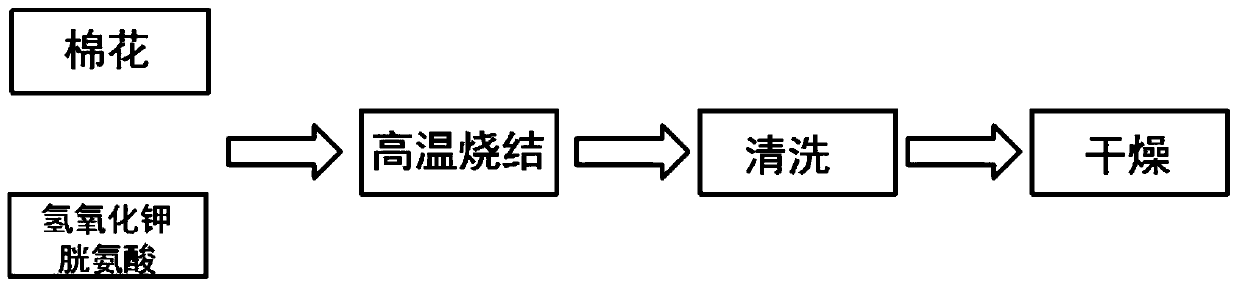

[0032] Firstly, the obtained cotton material is washed with clear water, and then put into a drying oven for drying at 60°C. Mix the dried cotton and potassium hydroxide in a mass ratio of 1:3 to prepare a potassium hydroxide solution and soak the cotton. Weigh cystine whose mass is twice that of cotton, put it into potassium hydroxide solution, and mix well. The solution is sealed and ultrasonically treated for a certain period of time, and placed in an environment with a temperature of 80° C. and sealed and soaked for 5 days, so that the cotton material is fully etched and activated. Then collect the soaked product. After the material is fully dried, put it into a small porcelain boat and put it in a tube furnace for calcination under an argon atmosphere. Set the temperature of the furnace to rise to 850°C at a rate of 3°C / min. And keep warm for 1h. After the furnace is naturally cooled to room temperature, the sample is taken out and fully ground, and then the sample is t...

Embodiment 2

[0034] Firstly, the obtained cotton material is washed with clear water, and then put into a drying oven for drying at 60°C. Mix the dried cotton and potassium hydroxide in a mass ratio of 1:3 to prepare a potassium hydroxide solution and soak the cotton. Weigh cystine whose mass is twice that of cotton, put it into potassium hydroxide solution, and mix well. The solution is sealed and ultrasonically treated for a certain period of time, and placed in an environment with a temperature of 80° C. and sealed and soaked for 5 days, so that the cotton material is fully etched and activated. Then collect the soaked product. After the material is fully dried, put it into a small porcelain boat and put it in a tube furnace for calcination under an argon atmosphere. Set the temperature of the furnace to rise to 850°C at a rate of 4°C / min. And keep warm for 1h. After the furnace is naturally cooled to room temperature, the sample is taken out and fully ground, and then the sample is t...

Embodiment 3

[0036] Firstly, the obtained cotton material is washed with clear water, and then put into a drying oven for drying at 60°C. Mix the dried cotton and potassium hydroxide in a mass ratio of 1:4 to prepare a potassium hydroxide solution and soak the cotton. Weigh cystine whose mass is twice that of cotton, put it into potassium hydroxide solution, and mix well. The solution is sealed and ultrasonically treated for a certain period of time, and placed in an environment with a temperature of 80° C. and sealed and soaked for 5 days, so that the cotton material is fully etched and activated. Then collect the soaked product. After the material is fully dried, put it into a small porcelain boat and put it in a tube furnace for calcination under an argon atmosphere. Set the temperature of the furnace to rise to 850°C at a rate of 4°C / min. And keep warm for 1h. After the furnace is naturally cooled to room temperature, the sample is taken out and fully ground, and then the sample is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com